Anti-aging additive for improving asphalt aging characteristic and preparation method of anti-aging asphalt

An aging performance and anti-aging technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of asphalt pavement becoming hard and brittle, prone to disease, shortening service life, etc., to achieve improved light aging performance and superior barrier performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 75 parts (parts by mass, the same below) of organic montmorillonite, 8 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 5 parts of tris[2,4 -di-tert-butylphenyl]phosphite, 6 parts of 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole and 6 parts of bis (2,2,6,6-tetramethyl-4-piperidinyl) sebacate is placed in a metal container with a top cover, and at room temperature utilizes a stirrer to stir at a rate of 1000rpm for 3min to obtain Anti-aging additives to improve the aging properties of bitumen.

[0025] The organic montmorillonite is obtained by organically intercalating sodium-based montmorillonite with cetyltrimethylammonium bromide, and the fineness of the organic montmorillonite is 200-400 mesh.

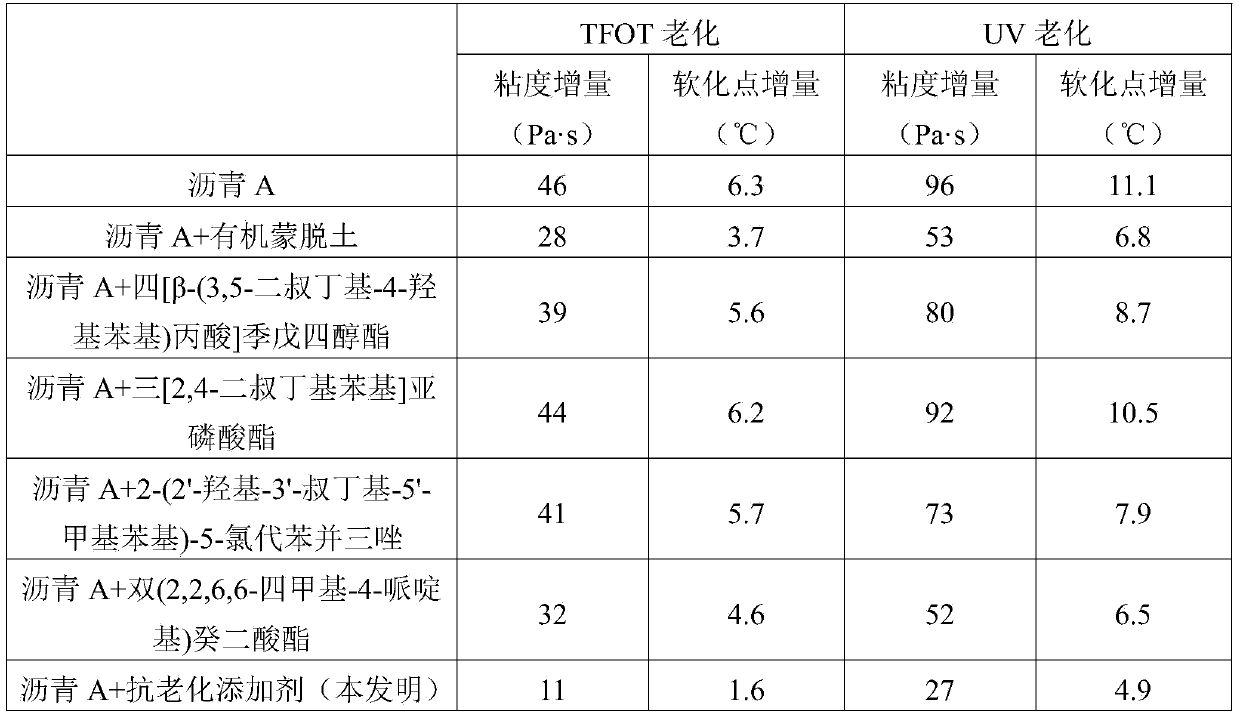

[0026] Heat 95 parts by mass of asphalt A (the said asphalt is road petroleum asphalt, with a penetration of 73dmm at 25°C and a softening point of 46.3°C) to 145-150°C, add 5 parts by mass of the above-mentione...

Embodiment 2

[0031] 75 parts of organic montmorillonite, 8 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 5 parts of tris[2,4-di-tert-butylphenyl ] phosphite, 6 parts of 2-hydroxy-4-n-octyloxybenzophenone and 6 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate In a metal container with a top cover, use a stirrer to stir at a rate of 1000 rpm for 3 minutes at room temperature to obtain an anti-aging additive for improving the aging performance of asphalt.

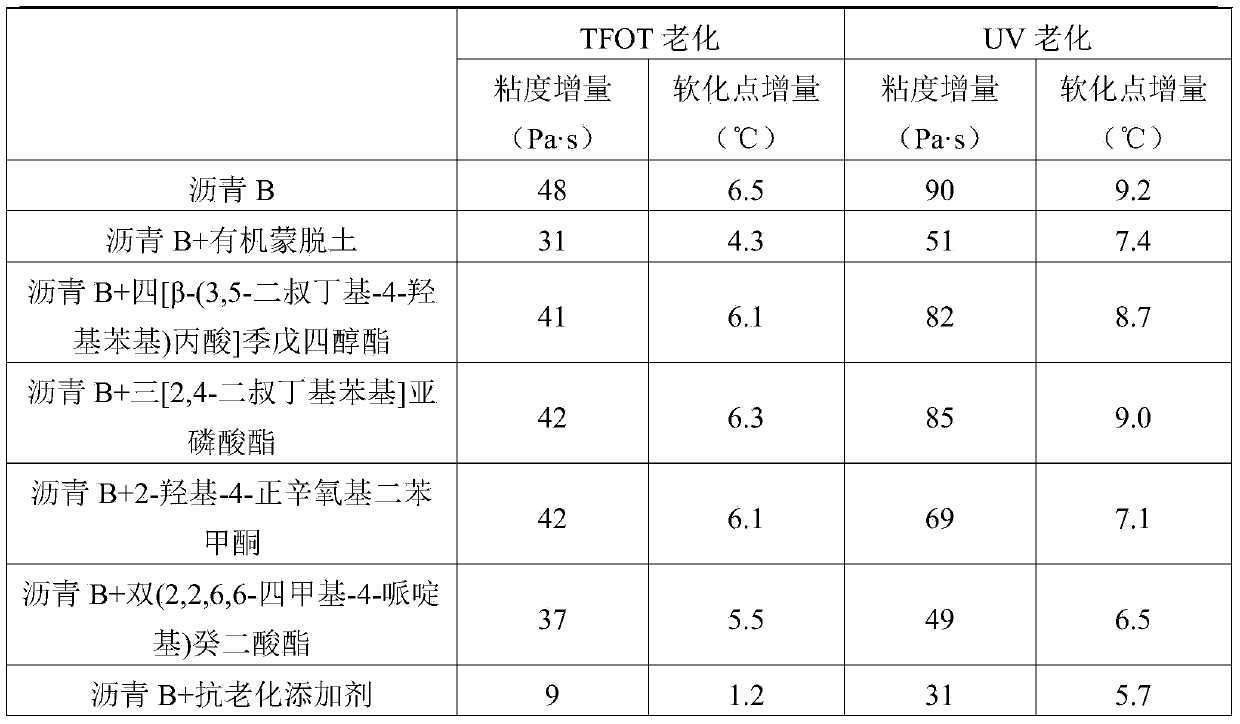

[0032] Heat 95 parts by mass of asphalt B (the said asphalt is road petroleum asphalt, with a penetration of 71dmm at 25°C and a softening point of 47.1°C) to 145-150°C, add 5 parts by mass of the above-mentioned anti-aging agent, and run at 4000rpm Stir for 30 minutes at a rotating speed to obtain aging-resistant asphalt. As a comparison sample, the asphalt was directly stirred at a temperature of 145-150°C at a speed of 4000rpm for 30 minutes, or 5 parts by mass of organic montmorillo...

Embodiment 3

[0037]78 parts of organic montmorillonite, 6 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 4 parts of tris[2,4-di-tert-butylphenyl ] phosphite, 4 parts 2-hydroxy-4-n-octyloxybenzophenone, 3 parts 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5- Chlorobenzotriazole and 5 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate were placed in a metal container with a top cover, and the Stirring at a rate of 1000 rpm for 3 minutes, the anti-aging additive for improving the aging performance of asphalt is obtained.

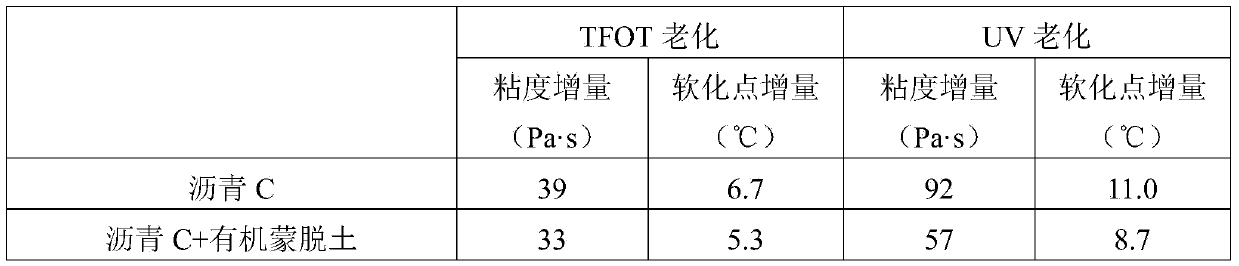

[0038] Heat 93 parts by mass of bitumen C (the said bitumen is road petroleum asphalt, with a penetration of 92dmm at 25°C and a softening point of 44.3°C) to 145-150°C, add 7 parts by mass of the above-mentioned anti-aging agent, at 4000rpm Stir for 30 minutes at a rotating speed to obtain aging-resistant asphalt. As a comparison sample, the asphalt was directly stirred at a speed of 4000 rpm for 30 minutes at a temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com