Preparation method of surface enhanced Raman scattering substrate based on spirogram ordered porous membrane

A surface-enhanced Raman and porous membrane technology, applied in the field of material chemistry, can solve the problems of high cost and poor enhancement effect, and achieve the effect of low cost, obvious Raman enhancement effect and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

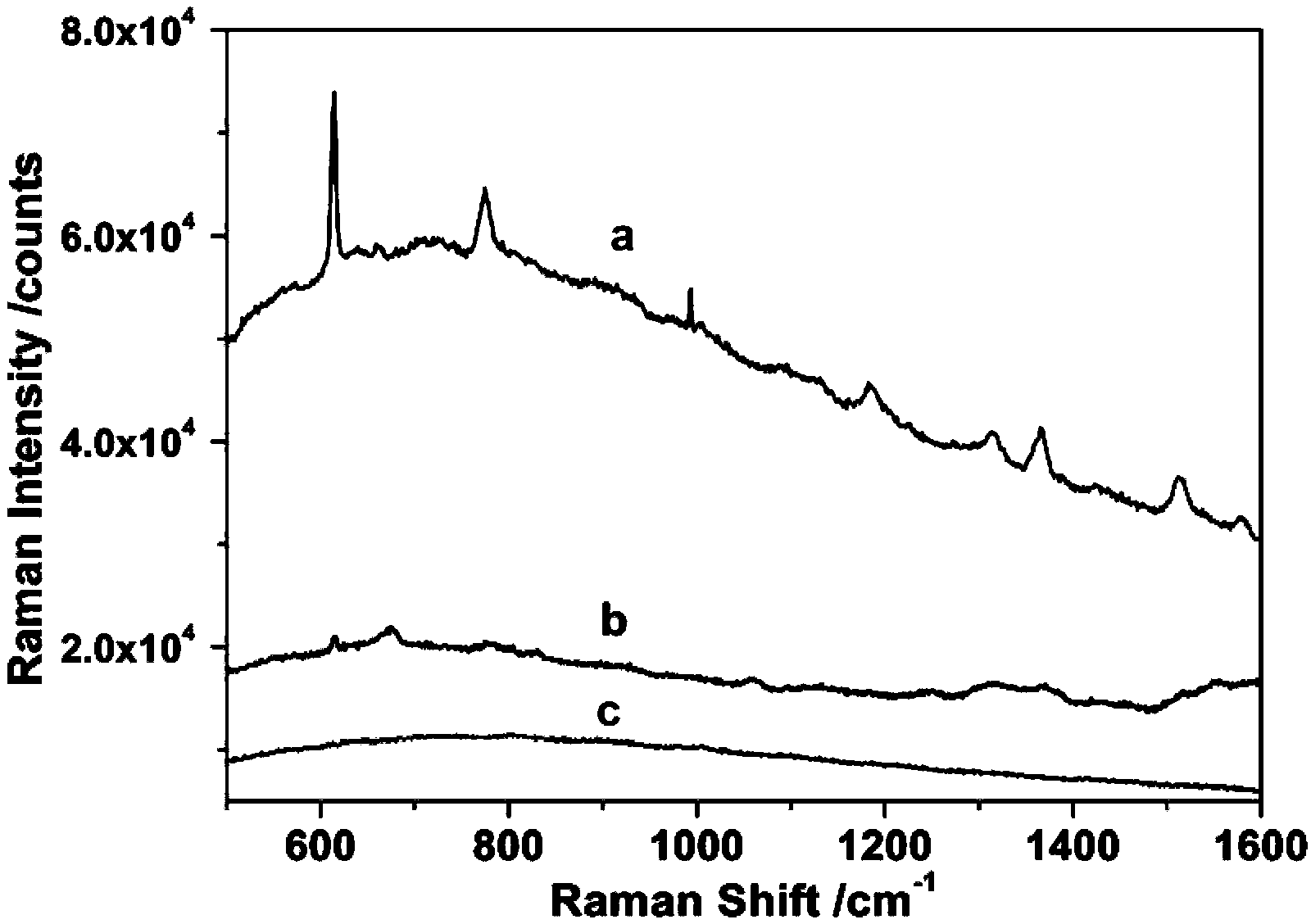

Embodiment 1

[0020] Styrene / dimethylaminoethyl methacrylate block copolymer (PS- b -PDMAEMA) was dissolved in carbon disulfide to prepare 2 mg / mL PS- b -PDMAEMA solution, PS- b -The molar percentage of styrene units in PDMAEMA is 90%, and 50 μL of PS- b -PDMAEMA solution is evenly spread on the polyester film, quickly placed in an environment with a relative humidity of 80%, and taken out after the solvent is volatilized, and an ordered porous membrane with a breath pattern is obtained, and the pore size is 2.0 μm; the preparation of polymethacrylic acid The ethanol solution of dimethylaminoethyl ester (PDMAEMA) has a concentration of 30 mg / mL, the number average molecular weight of PDMAEMA is 35 kg / mol, and the polydispersity coefficient is 1.5. Add 0.5 mL of PMAEMA solution dropwise on the surface of the prepared porous film with a respiration pattern, and spin-coat with a desktop homogenizer. The homogenization time I is 6 seconds, the speed is 0.5 thousand rpm, and the homogenization...

Embodiment 2

[0026] Styrene / hydroxyethyl methacrylate block copolymer (PS- b -PHEMA) was dissolved in dichloromethane to prepare 3 mg / mL PS- b -PHEMA solution, PS- b -The molar percentage of styrene units in PHEMA is 99%, and 50 μL of PS- b -The PHEMA solution is evenly spread on the polyimide film, quickly placed in an environment with a relative humidity of 60%, and taken out after the solvent volatilizes to obtain an ordered porous membrane with a respiration pattern, and its pore size is 2.0 μm; the preparation of PDMAEMA Ethanol solution, the concentration is 35 mg / mL, the number average molecular weight of PDMAEMA is 30 kg / mol, and the polydispersity coefficient is 2.0. Add 0.5 mL of PMAEMA solution dropwise on the surface of the prepared porous film with a respiration pattern, and spin-coat with a desktop homogenizer. The homogenization time I is 6 seconds, the speed is 0.5 thousand rpm, and the homogenization time II is 30 seconds. , and the rotating speed was 3,000 r / min to obt...

Embodiment 3

[0028] Styrene / acrylic block copolymer (PS- b -PAA) was dissolved in chloroform to obtain 5 mg / mL PS- b -PAA solution, PS- b -The molar percentage of styrene units in PAA is 95%, and 50 μL of PS- b - The PAA solution is evenly spread on the glassy carbon, quickly placed in an environment with a relative humidity of 70%, and taken out after the solvent volatilizes to obtain an ordered porous membrane with a breath pattern, and its pore size is 2.5 μm; prepare the ethanol solution of PDMAEMA, At a concentration of 25 mg / mL, the number average molecular weight of PDMAEMA is 40 kg / mol and the polydispersity coefficient is 1.8. Add 0.5 mL of PMAEMA solution dropwise on the surface of the prepared porous film with a respiration pattern, and spin-coat with a desktop homogenizer. The homogenization time I is 6 seconds, the speed is 0.5 thousand rpm, and the homogenization time II is 30 seconds. , and the rotating speed was 3,000 r / min to obtain the coated respiration pattern ordere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com