Graphene curled molybdenum trioxide nano-ribbons, and preparation method and application thereof

A technology of molybdenum trioxide and graphene, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of low conductivity, capacity loss, poor kinetic performance, etc., and achieve the effect of high specific capacity, simple process and excellent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] One-step hydrothermal preparation of graphene curled molybdenum trioxide nanoribbon battery cathode material, comprising the following steps:

[0030] 1) Preparation of molybdenum sol: Measure 40mL of hydrogen peroxide solution into a 100mL beaker, slowly add 4g of molybdenum powder into hydrogen peroxide, and the whole process is carried out in a cold water bath. After the molybdenum powder is added completely, stir in a cold water bath for 4 hours;

[0031] 2) Measure 5mL of the graphene dispersion prepared by the Hummer method and 30mL of the molybdenum sol prepared in step 1), stir in a 70°C water bath for 4h, transfer to a 50mL reaction kettle, keep it in a constant temperature box at 180°C for 6h, and then naturally Cool to room temperature;

[0032] 3) The product obtained in step 2) was washed with absolute ethanol for 3-4 times, and then dried in an oven at 80°C to obtain graphene curled molybdenum trioxide nanobelts.

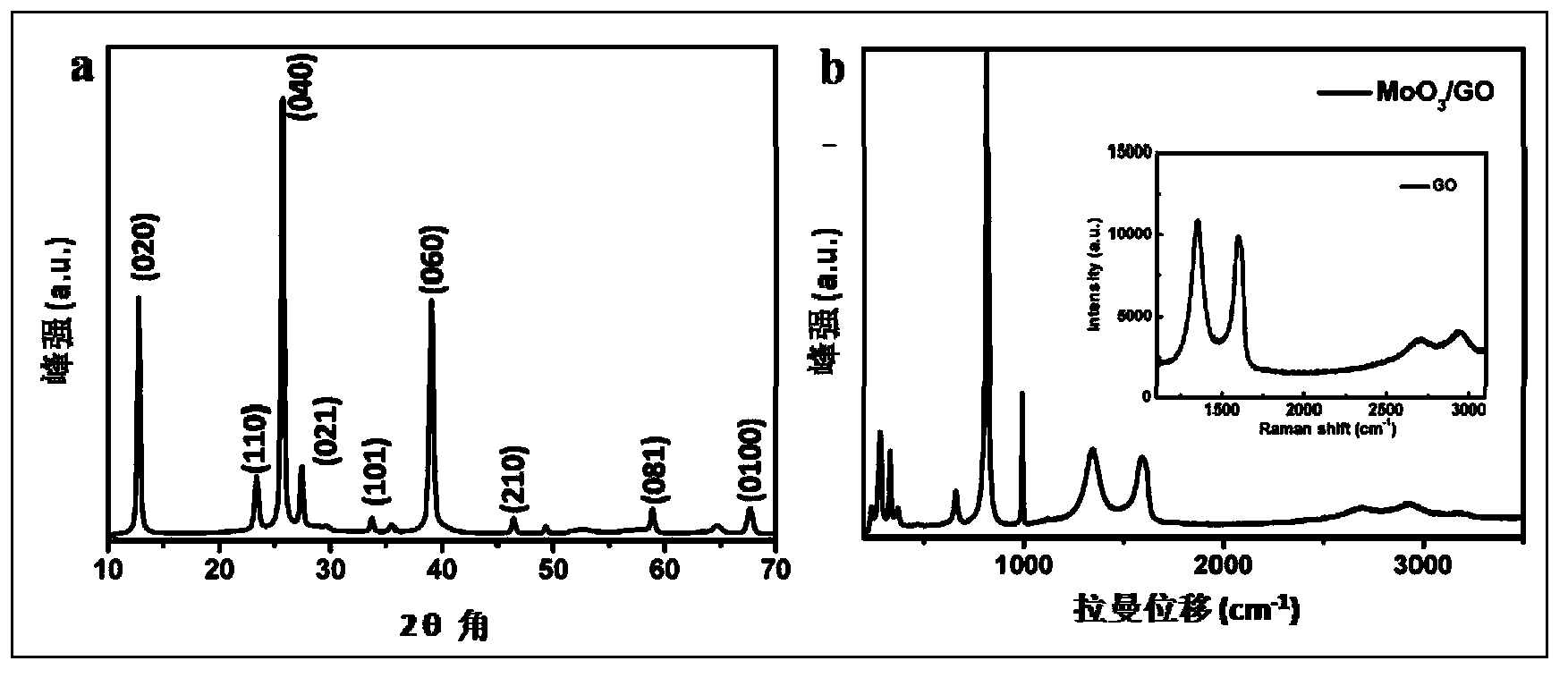

[0033] Such as figure 1 As shown, XRD ...

Embodiment 2

[0041] One-step hydrothermal preparation of graphene curled molybdenum trioxide nanoribbon battery cathode material, comprising the following steps:

[0042] 1) Preparation of molybdenum sol: Measure 40mL of hydrogen peroxide solution into a 100mL beaker, slowly add 4g of molybdenum powder into hydrogen peroxide, and the whole process is carried out in a cold water bath. After the molybdenum powder is added completely, stir in a cold water bath for 4 hours;

[0043] 2) Measure 5mL of the graphene dispersion prepared by the Hummer method and 30mL of the molybdenum sol prepared in step 1), stir in a 70°C water bath for 4h, transfer to a 50mL reactor, and keep it in a constant temperature box at 170°C for 6h, then Natural cooling to room temperature;

[0044] 3) The product obtained in step 2) was washed with absolute ethanol for 3-4 times, and then dried in an oven at 80°C to obtain graphene curled molybdenum trioxide nanobelts.

[0045]The graphene crimped molybdenum trioxide...

Embodiment 3

[0047] One-step hydrothermal preparation of graphene curled molybdenum trioxide nanoribbon battery cathode material, comprising the following steps:

[0048] 1) Preparation of molybdenum sol: Measure 40mL of hydrogen peroxide solution into a 100mL beaker, slowly add 4g of molybdenum powder into hydrogen peroxide, and the whole process is carried out in a cold water bath. After the molybdenum powder is added completely, stir in a cold water bath for 4 hours;

[0049] 2) Measure 5mL of the graphene dispersion prepared by the Hummer method and 30mL of the molybdenum sol prepared in step 1), stir in a water bath at 80°C for 4h, transfer to a 50mL reaction kettle, and keep it in an incubator at 190°C for 6h, then Natural cooling to room temperature;

[0050] 3) The product obtained in step 2) was washed with absolute ethanol for 3-4 times, and then dried in an oven at 80°C to obtain graphene curled molybdenum trioxide nanobelts.

[0051] The graphene crimped molybdenum trioxide n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com