Laser-gathering cavity for solid laser

A technology of solid-state lasers and concentrating cavities, which is applied to the structure/shape of optical resonators, can solve the problems of poor high temperature resistance, poor impact and vibration resistance of the diffuse reflection layer, and low reflectivity of the diffuse reflection layer. Strong shock and vibration resistance, high temperature resistance, and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

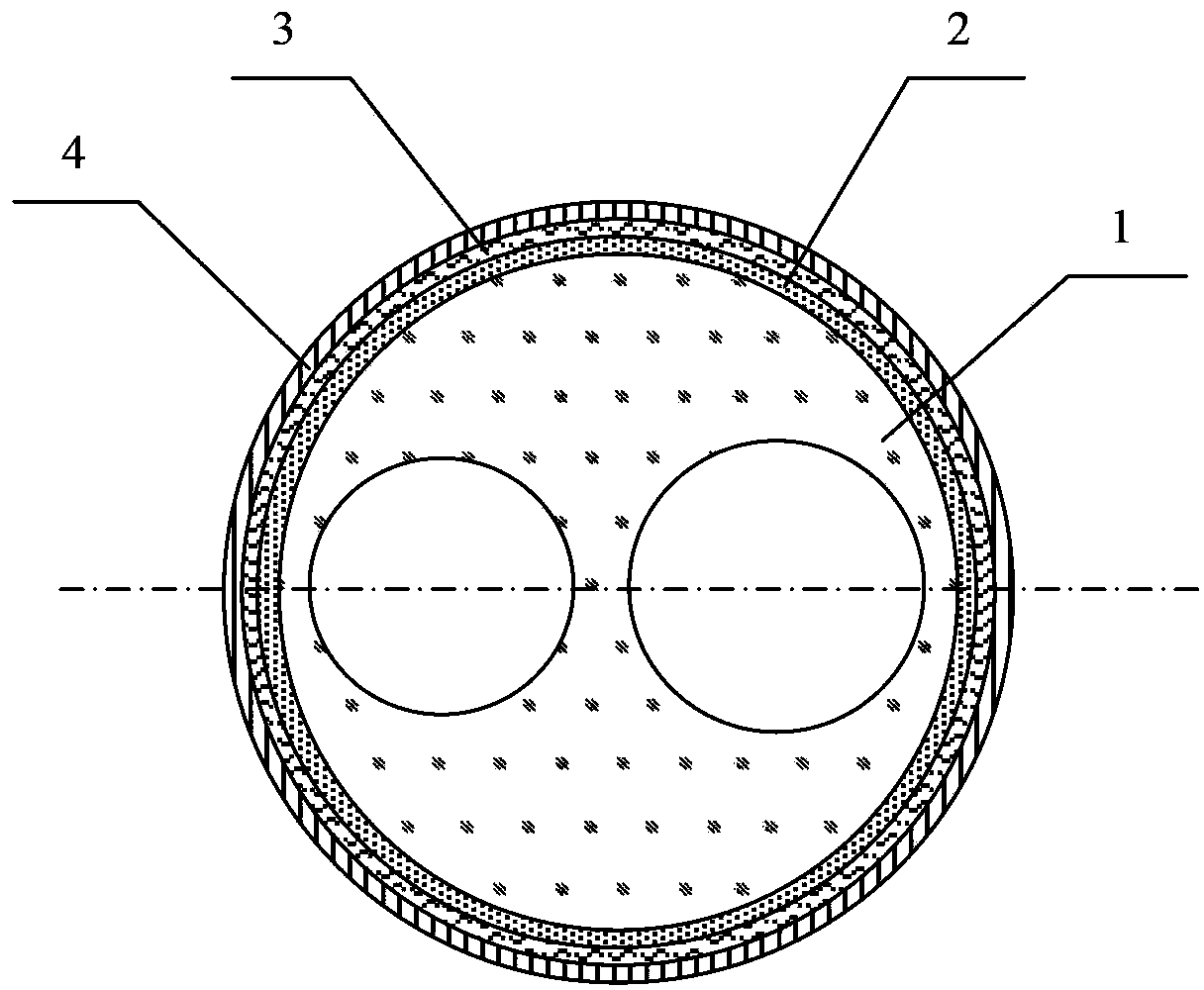

Embodiment 1

[0013] The shape of the quartz rod is cylindrical, and the diffuse reflection coating is sprayed with 0.3mm thick BaSO 4 powder, followed by a layer of SiO 2 The coating has a thickness of 50 μm; the metal reflective layer is made of silver and has a thickness of 0.2 mm.

[0014] The laser rod adopts Nd:YAG, diameter Ф15mm, and the pump lamp adopts pulsed xenon lamp. Gain measurement results show that for the pump cavity with this structure, the gain non-uniformity in the laser rod cross-section does not exceed 5%, and the calculation of the amplifier shows that this gain non-uniformity can obtain satisfactory radiation intensity uniformity at the output of the amplifier sex. It adopts the working mode of one-stage local oscillator and four-stage amplification, among which the four-stage amplification is manufactured by the light-collecting cavity, and obtains 100Hz, 3J, and pulse width of 10ns high peak power laser output, and the beam quality is better than 5mm*mrad. Due ...

Embodiment 2

[0016] The shape of the quartz rod is still cylindrical, and the diffuse reflection coating is sprayed with 0.15mm thick BaSO 4 powder, followed by a layer of SiO 2 The coating has a thickness of 100 μm; the metal reflective layer is made of silver material and has a thickness of 0.3 mm.

[0017] It adopts the working mode of one-stage local oscillator and four-stage amplification, among which the four-stage amplification is made of the light-collecting cavity, and obtains 5Hz, 6J, pulse width 10ns high peak power laser output, and the beam quality is better than 5mm*mrad. Due to the low repetition rate and high single pulse energy of this laser, the thickness of the diffuse reflection coating is appropriately reduced and the thickness of the metal reflection layer is increased. The laser is used in laser surface impact strengthening processing equipment, and has the advantages of small size, light weight, stability and reliability, and easy operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com