Bacillus laterosporus fermentation bed and manufacturing method thereof

A technology of Bacillus lateralosporus and its production method, which is applied in the field of poultry breeding, can solve the problems of incomplete decomposition of ammonia gas, troublesome cultivation process, and low activity of strains, so as to achieve a virtuous cycle and reduce the amount of manure cleaning labor and usage little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

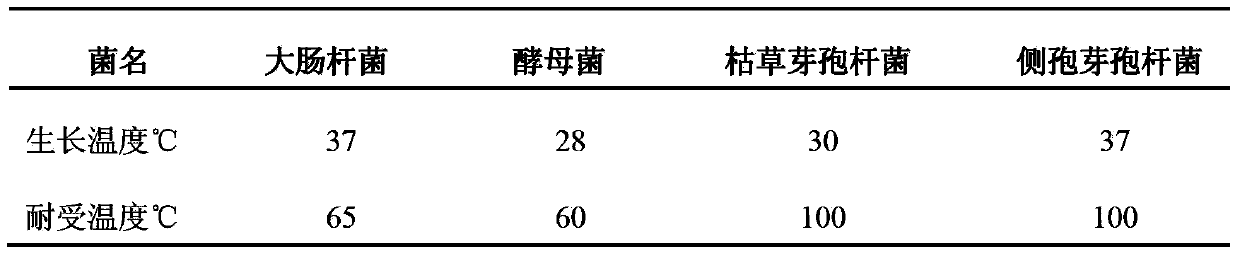

[0027] Preparation of the Bacillus lateralosporus preparation: inoculate the Bacillus lateralosporus on the above-mentioned culture medium, culture at 37° C. with shaking at 200 rpm, and spray-dry the preparation after most of the Bacillus lateralosporus forms spores. Each gram of Bacillus lateralis preparation contains 1×10 Bacillus lateralis 11 more than cfu.

[0028] The pad material is composed of chaff and sawdust, and the chaff and sawdust are composed in a volume ratio of 2-5:5-8. The litter is required to be free from mildew and insects.

[0029] During the brooding stage, about 10 litter materials are laid in the chicken house, and the mixture of litter materials and chicken manure cleaned up after the brooding stage is brooding chicken manure. Compared with using cornmeal or meat chaff as nutrients, the use of brooding chicken manure can reduce the investment cost of the farmer's fermentation bed. At the same time, the brooding chicken manure is fresh and mildew-fr...

Embodiment 1

[0032] Medium formula for cultivating Bacillus lateralosporus (g / L): corn starch 10; bran 10; corn steep liquor 18; (NH 4 ) 2 SO 4 1.5; 2 HPO 4 1.5; MgSO 4 2.0; CaCO 3 0.5; pH 7.0. After 15 minutes of autoclaving, the culture medium was inoculated with spores of Bacillus disspora. Spray-drying is carried out after most of the Bacillus lateralosporus in the culture medium form spores to prepare the Bacillus lateralosporus preparation.

[0033] During the brooding stage, about 3 cm of litter material is laid, and the brooding chicken manure cleaned up after the brooding stage is used for pre-fermentation. The litter material consists of chaff and sawdust in a volume ratio of 4:6.

[0034] The pre-fermentation litter is composed of litter material and brooding chicken manure in a volume ratio of 4:1, mixed evenly, inoculated with Bacillus lateralis, adjusted to 50% moisture, and pre-fermented in a hill shape of not less than 1 meter 6 sky. The inoculum amount is 1g B...

Embodiment 2

[0038] Medium formula for cultivating Bacillus lateralosporus (g / L): corn starch 8; bran 8; corn steep liquor 15; (NH 4 ) 2 SO4 1.0; Na 2 HPO 4 1.0; MgSO 4 1.0; CaCO 3 1.0; pH 7.0. After 15 minutes of autoclaving, the culture medium was inoculated with spores of Bacillus disspora. Spray-drying is carried out after most of the Bacillus lateralosporus in the culture medium form spores to prepare the Bacillus lateralosporus preparation.

[0039] During the brooding stage, about 5 cm of litter material is laid in the chicken coop, and the brooding chicken manure cleaned up after the brooding stage is used for pre-fermentation. The litter material consists of chaff and sawdust in a volume ratio of 5:5.

[0040] The pre-fermentation litter is composed of litter materials and brooding chicken manure in a volume ratio of 3:1, mixed evenly, inoculated with Bacillus lateralis, adjusted to a moisture content between 40%, and pre-fermented in a hilly pile of no less than 1 meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com