Exfoliating condensation and preparation method thereof

A technology of exfoliating and mass percentage, applied in the directions of pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of flocculent formation in production and storage, unsuitable for mass production, and high skin irritation, etc. Improves skin conditioning properties, enhances exfoliation, reduces irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

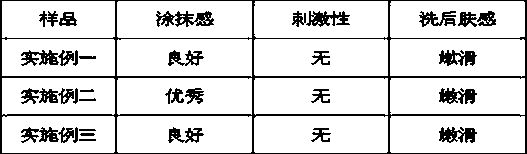

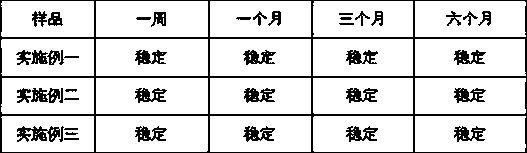

Examples

Embodiment 1

[0022] 1) Weigh 0.80% carbomer, 5.00% propylene glycol, 3.00% glycerin, 0.50% allantoin, 3.00% tetradecyltrimethylammonium chloride, 0.15% by mass of polyquaternium-10, natural hard Dextran 0.50%, methyl paraben 0.20%, methyl chloroisothiazolinone 0.20%, essence 0.05%, deionized water 86.60% spare;

[0023] 2) Add 86.60% deionized water into the reaction kettle, then sprinkle 0.80% carbomer, and start stirring after wetting, at a stirring speed of 45 rpm, until it is uniform and free of particles;

[0024] 3) Add 5.00% propylene glycol, 3.00% glycerin, and 0.50% allantoin, heat up to 85 degrees, keep stirring for 30 minutes at a stirring speed of 30 rpm, and stir until there are no particles for later use;

[0025] 4) Add 0.90% tetradecyltrimethylammonium chloride and 0.045% polyquaternium-10, and stir at a stirring speed of 25 rpm;

[0026] 5) Add 0.50% natural scleroglucan, 0.20% methylparaben, 0.20% methylchloroisothiazolinone, and 0.05% essence, and stir evenly at a stirr...

Embodiment 2

[0029] 1) Weigh 1.50% carbomer, 10.00% propylene glycol, 1.00% glycerin, 0.20% allantoin, 6.00% tetradecyltrimethylammonium chloride, 0.50% by mass polyquaternium-10, natural hard Dextran 1.00%, methyl paraben 0.20%, methyl chloroisothiazolinone 0.20%, essence 0.05%, deionized water 79.35% spare;

[0030] 2) Add 79.35% deionized water into the reaction kettle, then sprinkle 1.50% carbomer, and start stirring after wetting, at a stirring speed of 45 rpm, until it is uniform and free of particles;

[0031] 3) Add 10.00% propylene glycol, 1.00% glycerin, and 0.20% allantoin, heat up to 85 degrees, keep stirring for 30 minutes at a stirring speed of 30 rpm, and stir until there are no particles for later use;

[0032] 4) Add 1.8% tetradecyltrimethylammonium chloride and 0.15% polyquaternium-10, and stir at a stirring speed of 25 rpm;

[0033] 5) Add 1.00% natural scleroglucan, 0.20% methylparaben, 0.20% methylchloroisothiazolinone, and 0.05% essence, and stir evenly at a stirring...

Embodiment 3

[0036] 1) Weigh 2.50% carbomer, 8.00% propylene glycol, 5.00% glycerin, 0.10% allantoin, 10.00% tetradecyltrimethylammonium chloride, 0.80% by mass of polyquaternium-10, natural hard Dextran 2.00%, methyl paraben 0.20%, methyl chloroisothiazolinone 0.20%, essence 0.05%, deionized water 71.15% spare;

[0037] 2) Add 71.15% deionized water to the reaction kettle, then sprinkle carbomer 2.50%, and start stirring after wetting, at a stirring speed of 45 rpm, until it is uniform and free of particles;

[0038] 3) Add 8.0% propylene glycol, 5.0% glycerin, and 0.1% allantoin, heat up to 85 degrees, keep stirring for 30 minutes at a stirring speed of 30 rpm, and stir until there are no particles for later use;

[0039] 4) Add 3.00% tetradecyltrimethylammonium chloride and 0.24% polyquaternium-10, and stir at a stirring speed of 25 rpm;

[0040] 5) Add 2.00% natural scleroglucan, 0.20% methylparaben, 0.20% methylchloroisothiazolinone, and 0.05% essence, and stir evenly at a stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com