Method for removing oxygen-containing compound in hydrocarbon stream

A technology for compounds and hydrocarbons, used in the field of removing oxygenated compounds in hydrocarbon streams, can solve the problems of high activation temperature and low adsorption capacity of adsorbents, and achieve the effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

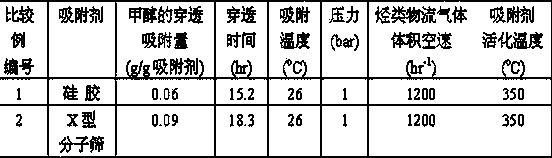

Examples

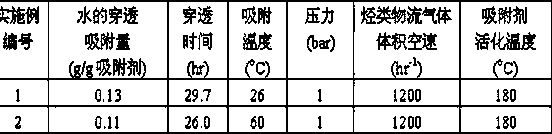

Embodiment 1

[0012] 1 g of fresh metal-organic compound adsorbent Cu 3 (BTC) 2 (H 2 O) 3 Loaded into a fixed bed reactor, at about 2000 hr -1 The bed was heated to 180°C in air for 2 hours and then cooled to 26°C. Then feed the propylene raw material containing 1000 ppm dimethyl ether, at 1200 hr -1 The time required for the concentration of dimethyl ether in the absorbed propylene stream to reach 1 ppm to pass through the bed of the adsorbent at a certain space velocity is recorded as the breakthrough time. Activation of solid adsorbent at 2000 hr -1 It is carried out in air, the activation temperature is 180°C, and the activation time is about 1 hour. The evaluation results are shown in Table 1.

[0013]

Embodiment 2

[0015] The adsorbent used is the organometallic compound Cu after adsorption and activation 10 times according to the conditions of Example 1. 3 (BTC) 2 (H2O) 3 , 1 gram of this adsorbent is packed into a fixed-bed reactor, and the adsorption test is carried out using the same conditions as in Example 1, and the evaluation results are shown in Table 1.

[0016]

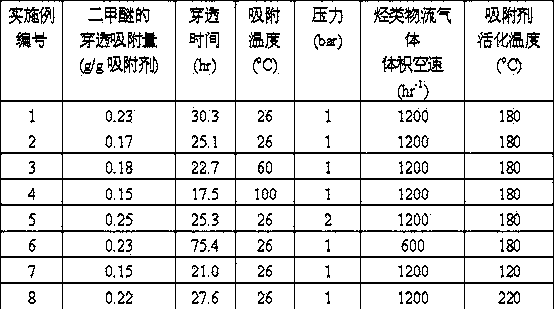

Embodiment 3~8

[0018] The solid adsorbent is fresh metal-organic compound adsorbent Cu 3 (BTC) 2 (H2O) 3 , Its consumption is the same as embodiment 1, and embodiment 3 and 4 change adsorption temperature relative to embodiment 1. Embodiment 5 changes the adsorption pressure relative to Embodiment 1. In Example 6, relative to Example 1, the gas volume space velocity of the hydrocarbon stream was changed, and in Embodiments 7 and 8, relative to Example 1, the activation temperature of the adsorbent was changed. See Table 1 for the experimental conditions and results of Examples 1-8.

[0019]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com