Forming technology for steel-plastic composite high-pressure-resistant type PE electric melting pipe fitting of secondary injection moulding forming

A secondary injection molding, steel-plastic composite technology, applied in the field of pipe fittings, can solve problems such as difficult to reach the pressure level, achieve good welding performance, improve dimensional accuracy, and improve the effect of welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

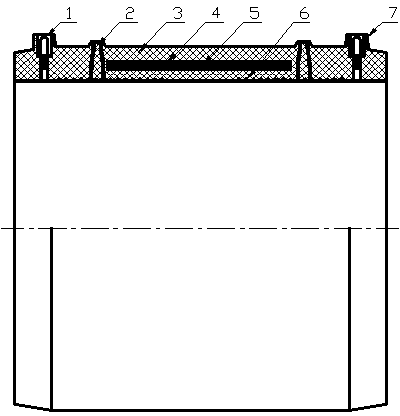

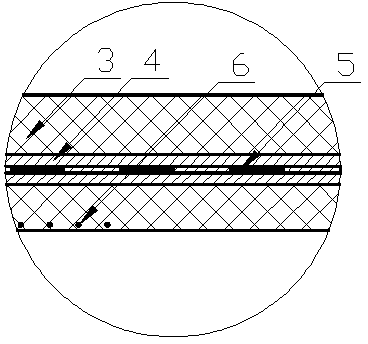

[0031] As shown in the picture, the two-shot injection molding steel-plastic composite high-pressure PE electric fusion pipe fitting:

[0032] It is mainly composed of electrode 1, observation hole 2, pipe fitting body 3, PE hot melt adhesive 4, stainless steel sleeve 5, resistance wire 6, electrode protective sleeve 7 and other components.

[0033] Among them, the electrode 1 is connected with the resistance wire 6 and is inserted into the pipe fitting body 3 in an interference fit manner to connect an electric welding machine, and connect an external power source to the pipe fitting to heat the resistance wire on the inner surface, thereby To achieve the function of welding with pipes.

[0034] The observation hole 2 is a small part of the pipe fitting body 3. Its function is to gradually increase the melting pressure generated by the welding melting during the electrofusion welding process. The observation hole 2 moves outward to characterize the welding quality and status.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com