Method for preparing fumed silica and anhydrous hydrofluoric acid by utilizing phosphatic fertilizer by-product fluosilicate as raw material

A technology of fumed silica and anhydrous hydrofluoric acid, applied in fluorine/hydrogen fluoride, silicon oxide, climate sustainability, etc., can solve the problems of not having fumed silica, large silica particles, etc. Achieve the effect of ensuring continuous operation, reducing pressure, and eradicating hidden dangers of system damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

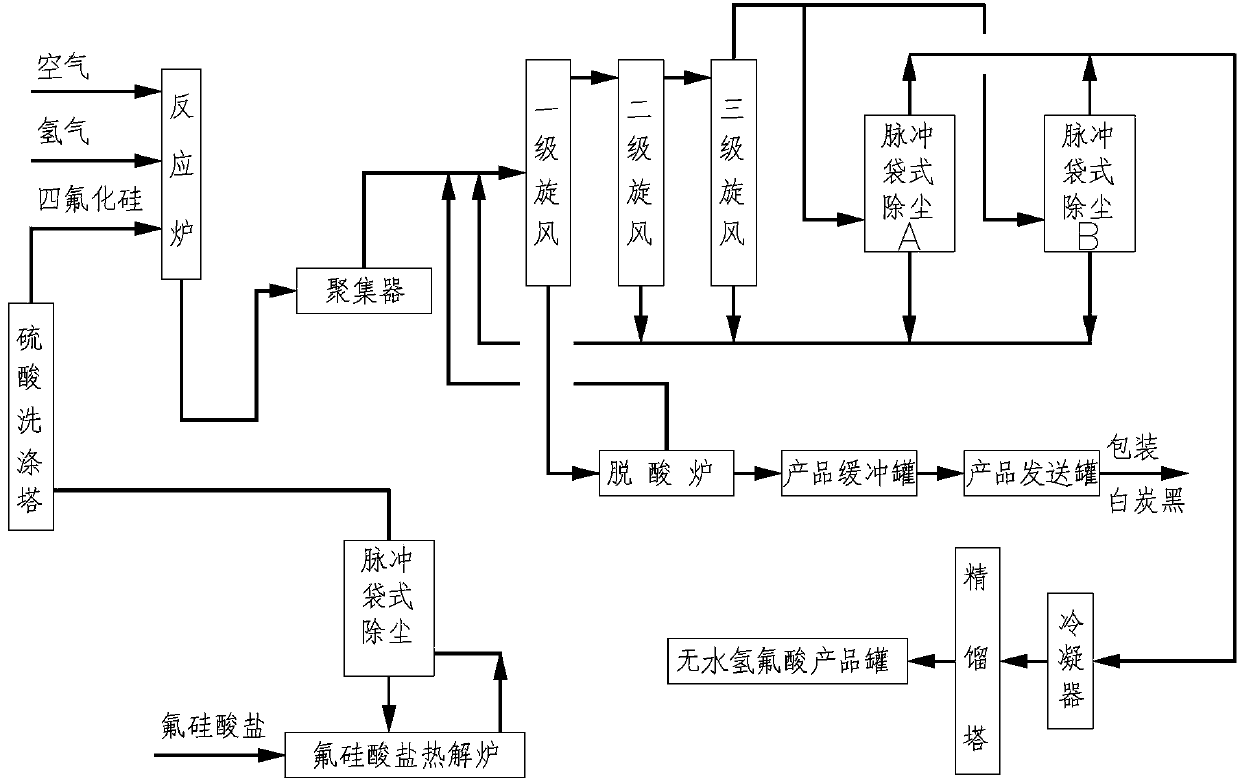

[0027] A method for preparing fumed white carbon black and anhydrous hydrofluoric acid with phosphate fertilizer by-product fluorosilicate as raw material, such as figure 1 shown, including the following steps:

[0028] (1) Preparation of silicon tetrafluoride: pyrolyze fluorosilicate, a by-product of phosphate fertilizer, at 300°C to obtain a gaseous silicon tetrafluoride crude product; cool the crude silicon tetrafluoride product to 75°C, and remove it through a filter After the dust is sent to the washing tower, the water and impurities contained in the silicon tetrafluoride are removed by washing with 96% concentrated sulfuric acid, and the silicon tetrafluoride product with a purity greater than 99.999% is obtained;

[0029] (2) Hydrolysis of silicon tetrafluoride: Send silicon tetrafluoride gas into the hydrolysis reactor, mix it with air and then evenly mix it with hydrogen. The volume ratio of hydrogen, air and silicon tetrafluoride is 1:2:0.2. The reaction temperatur...

Embodiment 2

[0035] A method for preparing fumed white carbon black and anhydrous hydrofluoric acid with phosphate fertilizer by-product fluorosilicate as raw material, such as figure 1 shown, including the following steps:

[0036] (1) Preparation of silicon tetrafluoride: pyrolyze fluorosilicate, a by-product of phosphate fertilizer, at 200°C to obtain a gaseous silicon tetrafluoride crude product; cool the crude silicon tetrafluoride product to 50°C, and remove it through a filter After the dust is sent to the washing tower, the water and impurities contained in the silicon tetrafluoride are removed by washing with 93% concentrated sulfuric acid, and the silicon tetrafluoride product with a purity greater than 99.999% is obtained;

[0037] (2) Hydrolysis of silicon tetrafluoride: Send silicon tetrafluoride gas into the hydrolysis reactor, mix it with air and then evenly mix it with hydrogen. The volume ratio of hydrogen, air and silicon tetrafluoride is 1:2:0.05. The reaction temperatu...

Embodiment 3

[0043] A method for preparing fumed white carbon black and anhydrous hydrofluoric acid with phosphate fertilizer by-product fluorosilicate as raw material, such as figure 1 shown, including the following steps:

[0044] (1) Preparation of silicon tetrafluoride: pyrolyze fluorosilicate, a by-product of phosphate fertilizer, at 400°C to obtain a gaseous silicon tetrafluoride crude product; cool the crude silicon tetrafluoride product to 100°C, and remove it through a filter After the dust is sent to the washing tower, the moisture and impurities contained in the silicon tetrafluoride are removed by washing with 98% concentrated sulfuric acid, and the silicon tetrafluoride product with a purity greater than 99.999% is obtained;

[0045] (2) Hydrolysis of silicon tetrafluoride: Send silicon tetrafluoride gas into the hydrolysis reactor, mix it with air and then evenly mix it with hydrogen. The volume ratio of hydrogen, air and silicon tetrafluoride is 1:2:0.3. The reaction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com