Method of processing sodium saccharin crystallized mother liquid

A technology of crystallizing mother liquor and sodium saccharin, which is applied in organic chemistry and other fields, and can solve problems such as increased production costs, waste, and insoluble saccharin that cannot be recycled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

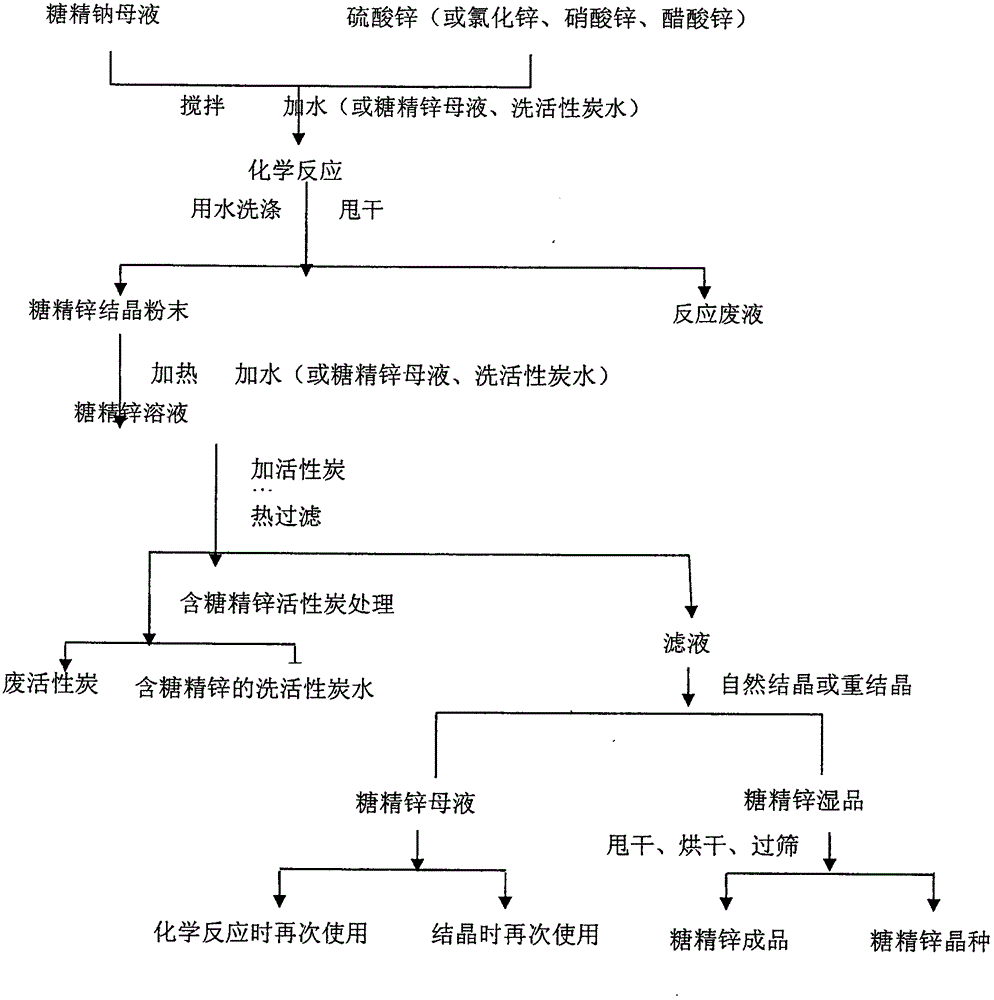

Image

Examples

Embodiment 1

[0019] Vacuum pump 2000kg of saccharin sodium crystallization mother liquor into a 5000L enamel decolorization kettle, measure its Baume concentration to be 27°Bé, take 200g of saccharin sodium crystallization mother liquor, add water to dilute to 11°Bé, add ice to cool to 5°C, add 30 Adjust % dilute sulfuric acid to pH=2.5 to generate oily impurities; separate oily impurity oil, continue to add 30% dilute sulfuric acid to the reaction solution to adjust to pH=1.0, generate saccharin, separate saccharin by suction filtration, drain and dry the saccharin, Obtain 49.2g of insoluble saccharin, thus it can be calculated that the anhydrous saccharin sodium contained in 200g of saccharin sodium crystallization mother liquor is: 49.2×205.19÷183.19=55.11g, wherein, 205.19 is the molecular weight of anhydrous saccharin sodium, and 183.19 is the molecular weight of insoluble saccharin . Then, the molecular weight of known zinc nitrate is 297.49, can calculate 2000kg saccharin sodium cry...

Embodiment 2

[0024] Vacuum pump 2000kg of saccharin sodium crystallization mother liquor into a 5000L enamel decolorization kettle, measure its Baume concentration to be 27.5°Bé, take 200g of saccharin sodium crystallization mother liquor, add water to dilute to 11°Bé, add ice to cool to 5°C, add 30 % dilute sulfuric acid is adjusted to pH=2.5 to generate oily impurities; to separate oily impurities, continue to add 30% dilute sulfuric acid to the reaction solution to adjust to pH=1.0 to generate saccharin, separate saccharin by suction filtration, drain and dry the saccharin to obtain The insoluble saccharin is 53.4g, so it can be calculated that the anhydrous saccharin sodium contained in the 200g saccharin sodium crystallization mother liquor is: 53.4×205.19÷183.19=59.81g, wherein, 205.19 is the molecular weight of anhydrous saccharin sodium, and 183.19 is the molecular weight of the insoluble saccharin. Then, the molecular weight of known zinc nitrate is 297.49, can calculate 2000kg sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com