Preparation method of environmentally-friendly halogen-free cold-stamping molded composite aluminum foil material

A composite aluminum foil, cold stamping technology, applied in chemical instruments and methods, lamination, lamination devices and other directions, can solve the problems of poor barrier properties, poor packaging barrier properties, unsolved halogen and PVC additives hazards, etc., to achieve a safe storage environment, Good barrier properties and prolong shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

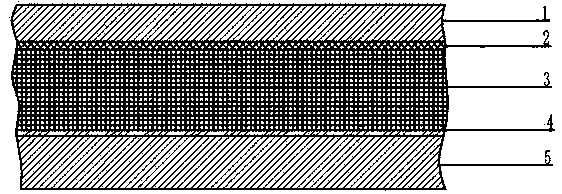

Embodiment 1

[0015] An environment-friendly halogen-free composite aluminum foil material that can be formed by cold stamping. The structure and thickness from outside to inside are: 25μm nylon layer 1, 3μm adhesive layer 2, 50μm aluminum foil layer 3, 3μm conversion layer 4 and 15μm added overgrowth Adhesive modified polyethylene heat seal layer 5. Prepared according to the following process steps and process parameters: (1) Chemical conversion treatment of aluminum foil: equipped with chemical conversion agents of the following concentrations: tannic acid 8.2g / L, phosphoric acid 0.04g / L, F - 0.4g / L, Ti salt 0.05g / L, adjust with NaOH to keep the pH value = 4.9, first use ethyl acetate to clean the oil on the surface of the aluminum foil, and then convert the temperature to 30-60°C and spray for 5-50 seconds Perform chemical conversion treatment on the aluminum foil, and dry it at 120°C for 35 seconds using an online drying equipment; %), 35% metallocene polyethylene, 52% polyethylene, 1...

Embodiment 2

[0017] An environmentally friendly halogen-free cold stamping composite aluminum foil material, the structure and thickness from outside to inside are: 15-25μm nylon layer 1, 3μm polyurethane adhesive layer 2, 40-60μm aluminum foil layer 3, 0.2-3μm chemical A conversion layer 4 and a 10-20 μm thermoplastic polyurethane heat-sealing layer 5 . Prepared according to the following process steps and process parameters: (1) Chemical conversion treatment of aluminum foil: equipped with the following concentration of chemical conversion agent: ammonium fluotitanate 10g / L, phytic acid 16g / L, silica gel 30g / L, PVA (polymerization degree 1400) 50g / L, adjust with NaOH to keep the pH value = 5.3, first use ethyl acetate to clean the oil on the surface of the aluminum foil, and then use a spreader at 10mg / m 2 The coating amount of the aluminum foil is chemically converted, and it is dried with 120°C hot air circulating air for 35 seconds on the online drying equipment; the silane coupling a...

Embodiment 3

[0019] An environment-friendly halogen-free composite aluminum foil material that can be formed by cold stamping. The structure and thickness from outside to inside are: 25μm nylon layer 1, 3μm polyurethane adhesive layer 2, 50μm aluminum foil layer 3, 3μm chemical conversion layer 4 and 15μm thermoplastic Polyurethane heat seal layer5. Prepared according to the following process steps and process parameters: (1) Chemical conversion treatment of aluminum foil: equipped with the following concentration of chemical conversion agent: ammonium fluotitanate 10g / L, phytic acid 16g / L, silica gel 30g / L, PVA (polymerization degree 1400) 50g / L, adjust with NaOH to keep the pH value = 5.3, first use ethyl acetate to clean the oil on the surface of the aluminum foil, and then use a spreader at 10mg / m 2 The coating amount of the aluminum foil is chemically converted, and it is dried for 35 seconds using an online drying equipment with hot air circulation at 120°C; (2) Heat-sealing layer ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| barrier rate | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com