Optical network-based automobile electric system

A technology for electrical systems and optical fiber networks, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve problems such as corrosion, scalability to be improved, high cost, etc., to achieve strong application and market prospects, component upgrades Simple and easy, avoids the effect of electrical short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

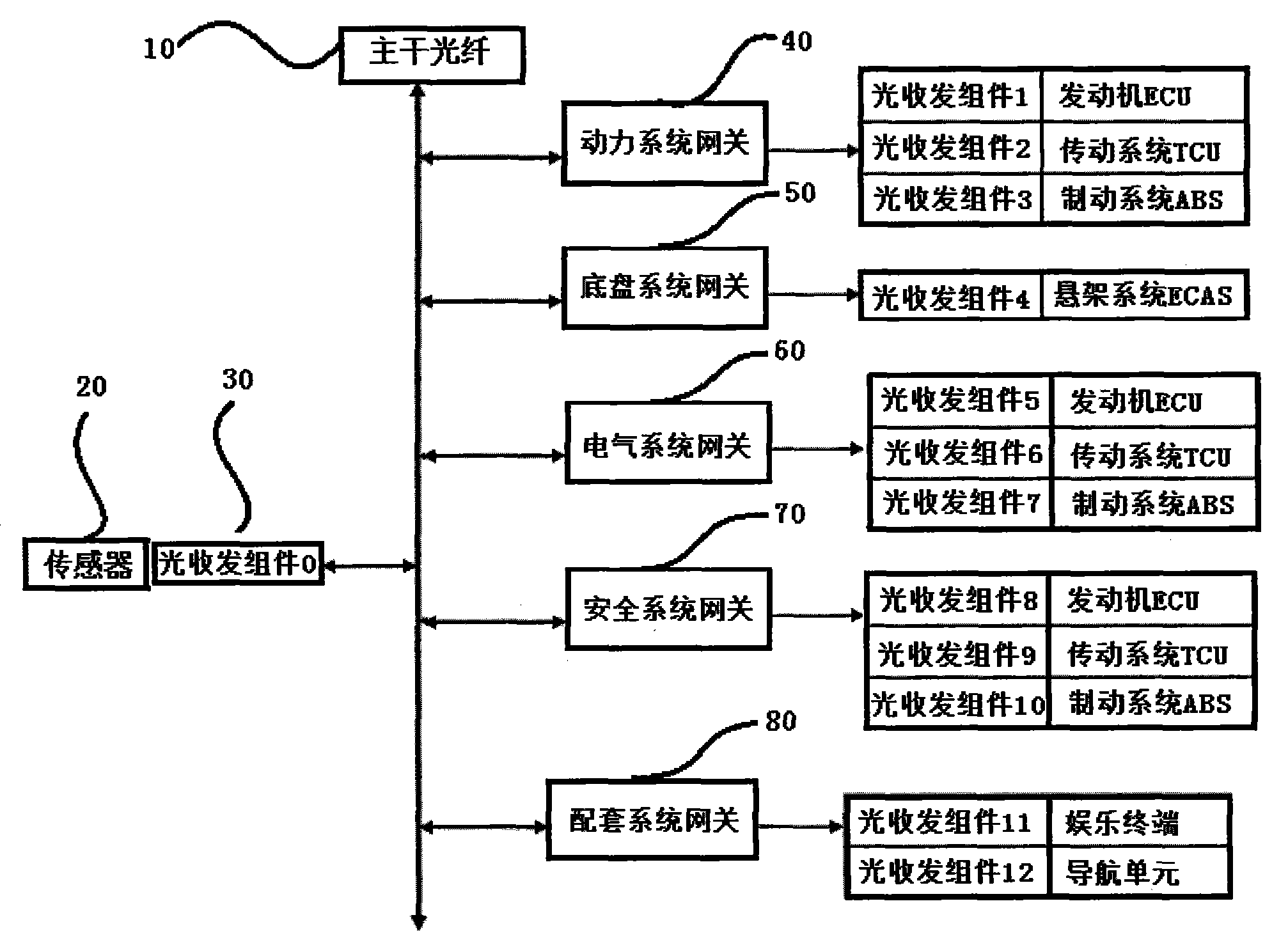

[0020] as attached figure 1 As shown, the automotive electrical system based on optical fiber network described in this embodiment adopts a bus structure, with a single backbone optical fiber as the backbone network, all sensors are shared through the backbone network, and each ECU is connected to the backbone network through a gateway. The system framework of the optical fiber network described in the present invention draws lessons from the design concept of GMLAN, a general company of the United States, and uses the specified architecture (OSI) for open system interconnection as a model to establish a high-speed and effective communication framework. According to the characteristics of automotive communication, the physical layer, data link layer, network layer, transport layer, and application layer are mainly introduced; the automotive electrical system based on optical fiber network developed based on this model can fully meet the needs of vehicle electrical systems now a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com