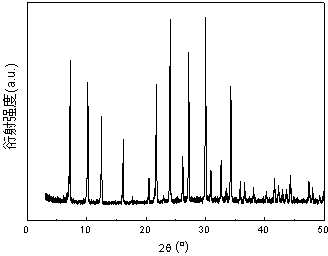

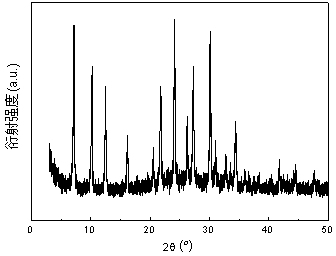

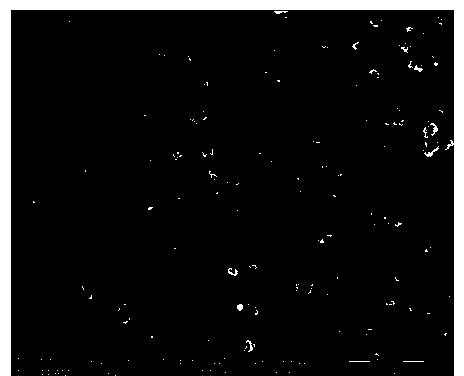

Rapid preparation method for A-type nano zeolite molecular sieve

A zeolite molecular sieve and nanotechnology, which is applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of long preparation period of nano A-type zeolite molecular sieve, shorten the synthesis period, inhibit the polycondensation rate, The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) by SiO 2 :Al 2 o 3 : Na 2 O: (TMA) 2 O: H 2 The molar ratio of O is 10.95: 1.8: 0.45: 14: 690. Weigh the reaction raw materials corresponding to the above substances, such as ethyl orthosilicate, aluminum isopropoxide, sodium hydroxide, tetramethylammonium hydroxide, deionized water, spare;

[0031] (2) Divide 27ml of deionized water in step (1) into two parts, one part accounts for 2 / 3 of the total volume, and the other part accounts for 1 / 3 of the total volume, and the volume accounts for 2 / 3 under stirring at 40°C Slowly add 2.29g of aluminum isopropoxide to 18ml of deionized water, and add 2.8g of sodium hydroxide solution with a concentration of 1mol / L, 15.9g of tetramethylammonium hydroxide (TMAOH 5H 2 (0), fully stir, prepare solution A;

[0032] (3) Add hydrochloric acid solution to 9ml of deionized water accounting for 1 / 3 of the volume, the pH of the solution after adding hydrochloric acid is = 5, and then slowly mix 7.1g of tetraethyl orthosilicate...

Embodiment 2

[0036] (1) by SiO 2 :Al 2 o 3 : Na 2 O: (TMA) 2 O: H 2 The molar ratio of O is 12.2: 1.89: 0.56: 15: 780. Weigh the reaction raw materials corresponding to the above substances, such as tetraethyl orthosilicate, aluminum powder, sodium hydroxide, tetramethylammonium hydroxide, deionized water, spare;

[0037] (2) Divide 36ml of deionized water in step (1) into two parts, one part accounts for 2 / 3 of the total volume, and the other part accounts for 1 / 3 of the total volume, and the volume accounts for 2 / 3 under stirring at 30°C Slowly add 0.38g of aluminum powder to 24ml of deionized water, and add it in one hour, then add 4.15g of sodium hydroxide solution with a concentration of 1mol / L, 21.5g of tetramethylammonium hydroxide (TMAOH·5H 2 (0), fully stir, prepare solution A;

[0038] (3) Add nitric acid solution to 12ml of deionized water accounting for 1 / 3 of the volume, the pH of the solution after adding nitric acid is 1, and then slowly mix 9.3g of tetraethyl orthosi...

Embodiment 3

[0042] (1) by SiO 2 :Al 2 o 3 : Na 2 O: (TMA) 2 O: H 2 The molar ratio of O is 5:1:0.2:10:500, and the reaction raw materials corresponding to the above substances are weighed orthosilicate ethyl ester, gibbsite, sodium hydroxide, tetramethylammonium hydroxide, deionized water, etc., spare;

[0043] (2) Divide 33ml of deionized water in step (1) into two parts, one part accounts for 2 / 3 of the total volume, and the other part accounts for 1 / 3 of the total volume, and the volume accounts for 2 / 3 under stirring at 35°C Slowly add 0.76g gibbsite in 22ml of deionized water, add 1.95g concentration and be 1mol / L sodium hydroxide solution, 17.4g tetramethylammonium hydroxide (TMAOH·5H 2 (0), fully stir, prepare solution A;

[0044] (3) Add sulfuric acid solution to 11ml of deionized water accounting for 1 / 3 of the volume, the pH of the solution after adding sulfuric acid is 3, and then slowly mix 4.91g of ethyl orthosilicate at a rate of 0.3ml / min under magnetic stirring at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com