Nanometer fabric finishing agent as well as preparation method and application thereof

A fabric finishing agent, nanotechnology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of low stability of finishing agents, easy aggregation and sedimentation of nanoparticles, and achieve excellent anti-ultraviolet and antibacterial and anti-mildew properties. The effect of a single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

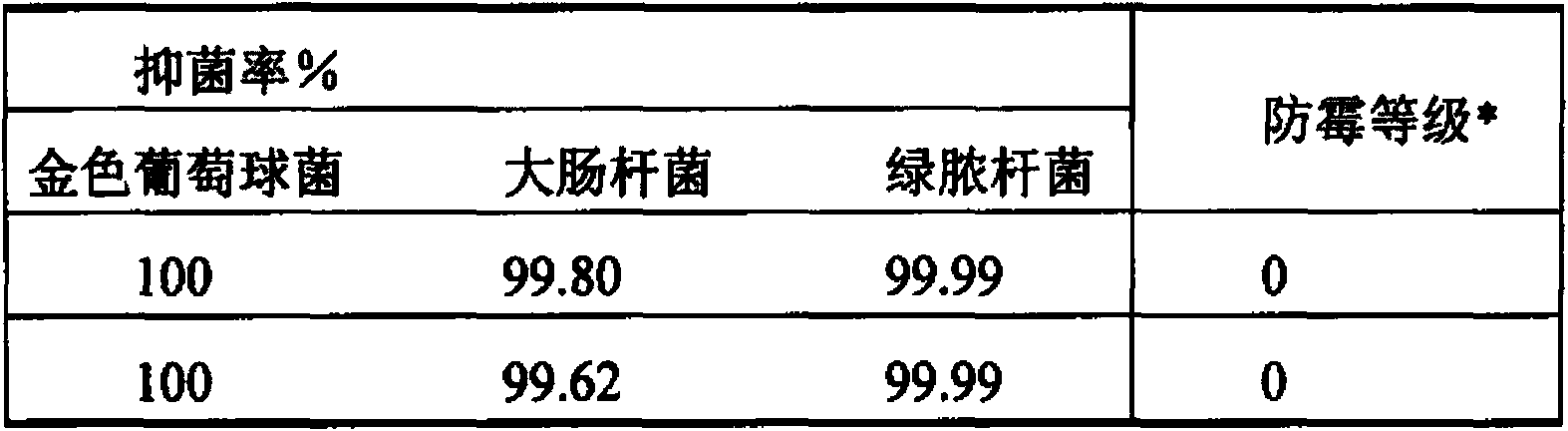

[0028] Preparation of a nano-ultraviolet and antimicrobial polyester fabric

[0029] (1) Preparation of finishing agent: Mix 50g of ethanol and 850g of water evenly, add an appropriate amount of dilute sulfuric acid, adjust the pH value to 3-4, add 50g of nano-zinc oxide powder, and disperse at a high speed of 2000 rpm with an emulsifier 20 minutes, then add 5g silane coupling agent KH560, continue to stir at high speed for 30 minutes, then add 0.2g triclosan, 10g sodium carboxymethylcellulose and 15g water-soluble polyurethane (such as the Impranil series of Bayer in Germany, or Japan Elastron series of Daiichi Pharmaceutical, etc.), and then continue to stir for 1 hour to obtain a white slurry with good stability, that is, a finishing agent;

[0030] (2) Finishing of fabrics: Pure polyester filament fabrics are processed according to the following processes: washing (removing surface sizing or oiling agent), impregnation at room temperature (1.5kg fabric with 1kg finishing a...

Embodiment 2

[0032] Preparation of a nano-ultraviolet and antimicrobial polyester-cotton (40 / 60) blended fabric

[0033] (1) Preparation of finishing agent: Mix 350g of ethanol and 450g of water evenly, add appropriate amount of NaOH dilute solution, adjust the pH value to 11-12, add 12g of nano-titanium dioxide powder, and use an emulsifier to disperse at a high speed of 1500 rpm 10 minutes, then add 3g titanate coupling agent NXT-105, continue to stir at high speed for 25 minutes, then add 1.5g butylparaben, 12g polyacrylamide and 10g water-soluble polyurethane (such as the Impranil series of German Bayer , or the Elastron series of Daiichi Pharmaceutical, etc.), and then continue to stir for 40 minutes to obtain a white slurry with good stability, that is, a finishing agent;

[0034] (2) Finishing of fabrics: Polyester-cotton fabrics are processed according to the following processes: washing (removing surface sizing or oiling agent), impregnating at room temperature (1.5kg fabric with ...

Embodiment 3

[0036] Preparation of a nano-ultraviolet and anti-microbial silk fabric

[0037] (1) Preparation of finishing agent: Mix 20g of ethanol and 980g of water evenly, add appropriate amount of NaOH dilute solution, adjust the pH value to about 10, add 25g of nano-zinc oxide and 5g of titanium dioxide mixed powder, use an emulsifier at 2500 rpm Disperse at high speed for 20 minutes, then add 5g of titanate coupling agent NXT-101, continue stirring at high speed for 30 minutes, and then add 20g of 2.5%wt 5-chloro-2methyl-4-isothiazoline- 3-ketone aqueous solution, 15g sodium alginate and 60g polymethyl acrylate and butyl ester copolymer emulsion (solid content 40%), and continue to stir for 1 hour to obtain a white slurry with good stability, that is, a finishing agent;

[0038](2) Finishing of fabrics: Silk fabrics are processed according to the following processes: washing (removing surface sizing or oiling agent), impregnation at room temperature (2kg fabric with 1kg finishing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com