Fiber net wet forming technology and special device thereof

A special device and fiber web technology, used in textiles and papermaking, paper machines, papermaking, etc., can solve the problems of increasing raw material costs, product pulling and cracking, etc., to save raw material costs, avoid pulling cracks, and reduce anisotropy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

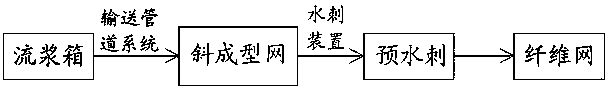

[0028] Embodiment 1: with reference to attached figure 1 . A fiber web wet forming technology, comprising the following steps:

[0029] ① Set the forming net in the forming equipment to be inclined;

[0030] ②In the forming equipment, a spunlace device is installed above the forming net;

[0031] ③The fiber raw material is placed in the water medium to open and loosen into single fibers, and mixed to form a fiber suspension slurry, which is placed in the headbox;

[0032] ④The fiber suspension slurry in the headbox is transported to the forming wire of the forming equipment through the pipeline system. The fiber suspension slurry settles under the action of negative pressure suction and gravity. Due to the blocking of the forming wire, the fibers settle evenly on the surface of the forming wire ;

[0033] ⑤The spunlace device in the forming equipment sprays the high-pressure fine water flow onto the fibers on the surface of the forming net to make the fibers entangle with ...

Embodiment 2

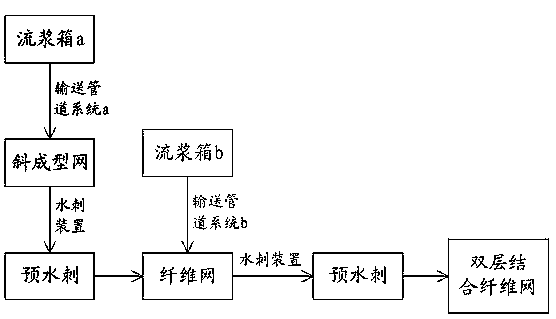

[0035] Embodiment 2: on the basis of embodiment 1, with reference to appended figure 2 . A fiber web wet forming technology also includes the following steps:

[0036] ⑦ After the first layer of fiber web is formed, repeat steps ④ to ⑥ to form a fiber web combined with two layers of fiber web on the basis of the first layer of fiber web; the fiber suspension slurry input to the forming net twice is Two fiber suspension slurries made from different fiber raw materials are placed in headbox a and headbox b respectively.

Embodiment 3

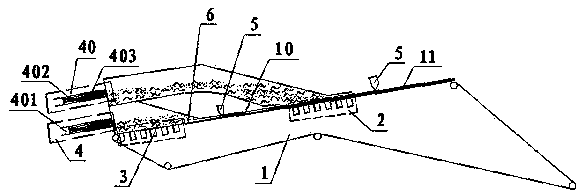

[0037] Embodiment 3: with reference to attached image 3. A special fiber web forming device for the fiber web wet forming technology in Example 2, including an inclined wire former 1 and a hydroentanglement device installed inside the inclined web former 1; the hydroentanglement head 5 of the hydroentanglement device is located on the forming net 6; the angle between the forming wire 6 in the inclined wire former 1 and the horizontal plane is 5° to 30°; on the inclined wire former 1, there are two sets of pipeline systems a4 and Piping system b40; the inclined wire former 1 is also provided with two groups of spunlace devices and two groups of dewatering boxes 2; the dewatering boxes 2 are located below the forming net 6, and the dewatering boxes 2 are composed of multiple independent The adjusted dehydration chamber 3 is composed of; the dehydration box 2 and the hydroentanglement head 5 of the hydroentanglement device are arranged at intervals; the piping system a4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com