Fireproof and water proof photovoltaic coiled material and method for preparing same

A waterproof coiled material and coiled material technology, used in photovoltaic power generation, roof insulation materials, sustainable buildings, etc., can solve the problems of large environmental and human influence factors, high labor costs, and high prices, and reduce wet construction. link, overcome the flammability of organic matter, and ensure the effect of overall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

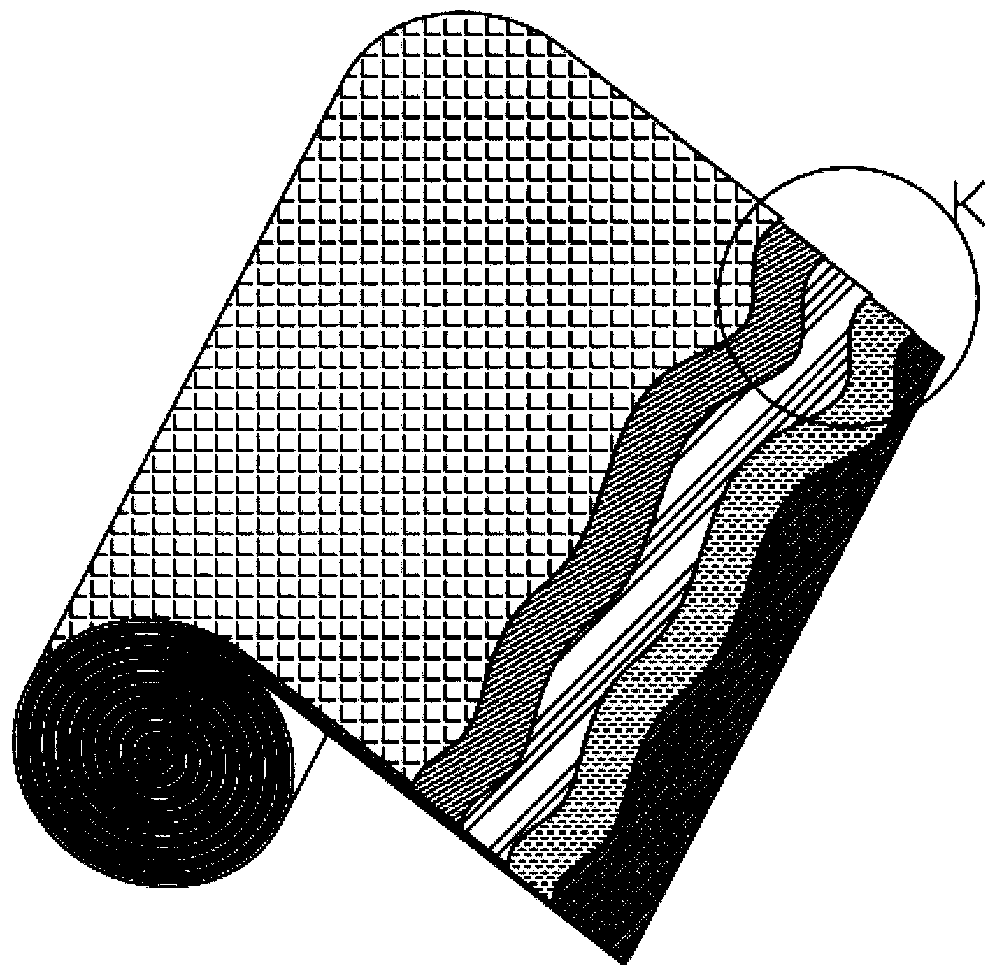

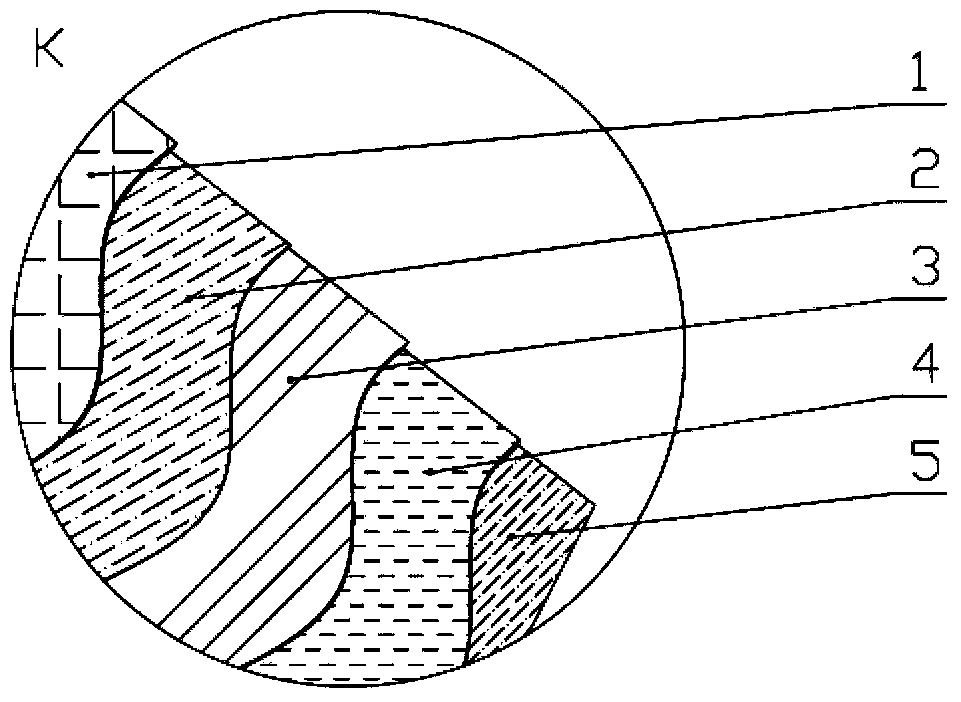

[0029] Such as figure 1 and figure 2As shown, a fireproof and waterproof photovoltaic coiled material has a layered structure, which sequentially includes a waterproof coiled material substrate 1, an adhesive layer 2, a flexible thin film photovoltaic cell module 3, a film layer 4 and a paint layer 5 from inside to outside. The waterproof coiled material substrate uses high-tough glass fiber reinforced flame-retardant non-woven fabric as the base, and the two sides of the base base are scraped with flame-retardant modified polymer cement mortar; wherein the high-tough glass fiber reinforced flame-retardant non-woven fabric is used The material adopts Anfang flame-retardant fiber (viscose fiber) and 4080 fiber (low-melting fiber), which has excellent flame-retardant and anti-melting effects, and can effectively form a flame-retardant firewall. Among them, the main raw materials of the flame-retardant polymer modified cement mortar layer are calculated in parts by weight: 12-1...

Embodiment 2

[0033] A fire-proof and waterproof photovoltaic coil, the thickness of the waterproof coil substrate 1 is 1.2mm; the flexible thin-film photovoltaic cell assembly 3 is an organic thin-film battery; the coating layer 5 is a nano-scale fluorocarbon coating with a thickness of 70um; The flame-retardant polymer modified cement mortar is composed of the following raw materials in parts by weight: 17 parts of ordinary silicon 425 cement, 38 parts of quartz sand, 23 parts of propionic acid emulsion, 15 parts of water, and 7 parts of composite flame retardant; example 1.

Embodiment 3

[0035] A fire-proof and waterproof photovoltaic coil, the thickness of the waterproof coil substrate 1 is 1.8mm; the flexible thin-film photovoltaic cell assembly 3 is a copper indium potassium selenium thin-film solar cell; the coating layer 5 is nano-scale organosilicon modified Acrylic paint with a thickness of 50um; the flame retardant polymer modified cement mortar is composed of the following raw materials in parts by weight: 18 parts of ordinary silicon 42.5 cement, 36 parts of quartz sand, 24 parts of propionic acid emulsion, 14 parts of water, composite flame retardant 7 parts of agent; Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com