A light porous melamine resin transboundary capture material and its preparation process

A technology of transboundary capture material and melamine resin, which is applied in the field of lightweight porous melamine resin transboundary capture material and its preparation, can solve the problem that it is difficult to meet the requirements of EMAS materials, and overcome the flammability and resistance of general sprayed organic matter. Good frost resistance and antifreeze performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

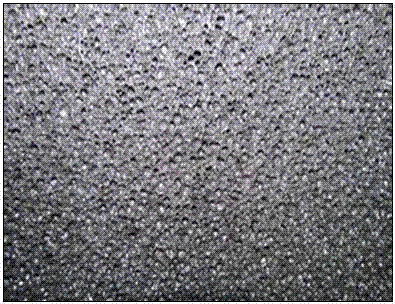

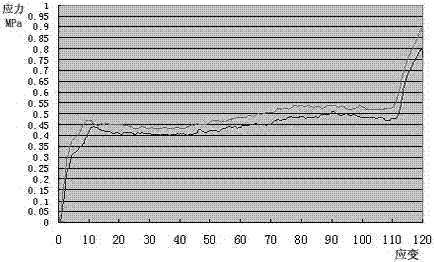

Image

Examples

Embodiment 1

[0055] A preparation process for a lightweight porous melamine resin transboundary capture material, comprising the following steps:

[0056] 1) Preparation of suspension: Dissolve 100 parts by weight of melamine formaldehyde resin in 33.3 parts by weight of water, add 300 parts by weight of a mixture of petrolatum and montmorillonite, 15 parts by weight of alkylphenol polyoxyethylene ether, 60 parts by weight of n-pentyl Alkanes and normal hexane mix blowing agent, 22 parts by weight of sulfuric acid by 1:1, stir and mix uniformly to form stable slurry, the particle diameter of described stone fat and montmorillonite is 1mm, and described melamine formaldehyde resin is melamine, The precondensate of formaldehyde, the molar ratio of melamine and formaldehyde is 1:1 when it is synthesized;

[0057] 2) Put the slurry prepared in step 1) in a 2450MHz tunnel-type microwave heating furnace at a temperature of 80°C, foam and solidify for 1.8 hours, and the slurry undergoes a curing ...

Embodiment 2

[0063] A preparation process for a lightweight porous melamine resin transboundary capture material, comprising the following steps:

[0064] 1) Preparation of suspension: Dissolve 100 parts by weight of melamine formaldehyde resin in 33.3 parts by weight of water, add 400 parts by weight of a mixture of vermiculite and illite, 20 parts by weight of fatty acid polyethylene glycol ether, 70 parts by weight of petroleum ether, 25 parts by weight part formic acid, stirring and mixing uniformly to form stable slurry, the particle diameter of described vermiculite and illite is 0.5mm, and described melamine-formaldehyde resin is the precondensate of melamine, formaldehyde, and the mol ratio of melamine and formaldehyde is 2 during its synthesis :1;

[0065] 2) Put the slurry prepared in step 1) in a 2000MHz tunnel-type microwave heating furnace at a temperature of 75°C, foam and solidify for 2 hours, and the slurry undergoes a curing reaction to form a lightweight porous material, ...

Embodiment 3

[0071] A preparation process for a lightweight porous melamine resin transboundary capture material, comprising the following steps:

[0072] 1) Preparation of suspension: Dissolve 100 parts by weight of melamine formaldehyde resin in 33.3 parts by weight of water, add 500 parts by weight of a mixture of allophane and apophyllite, 25 parts by weight of alkyltrimethylammonium salt, and 80 parts by weight of n-hexyl Alkane, 28 parts by weight of acetic acid, stirred and mixed uniformly to form a stable slurry, the particle diameter of the allophane and apophyllite is 0.1mm, and the melamine-formaldehyde resin is a precondensate of melamine and formaldehyde, and melamine is synthesized The molar ratio with formaldehyde is 3:1;

[0073] 2) Put the slurry prepared in step 1) in a 915MHz tunnel-type microwave heating furnace at a temperature of 75°C, foam and solidify for 2 hours, and the slurry undergoes a curing reaction to form a lightweight porous material, which is then dried n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com