Capacitive temperature, humidity and air pressure sensor integrated manufacturing method based on SOI chip device layer silicon anodic bonding

An air pressure sensor and humidity sensor technology, which is applied in the integrated manufacturing of humidity and air pressure sensors, and capacitive temperature fields, can solve the problems of increased research and development costs, increased research and development difficulty, and long interconnection lines, and achieves improved system reliability and interconnection lines. The effect of length reduction and area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

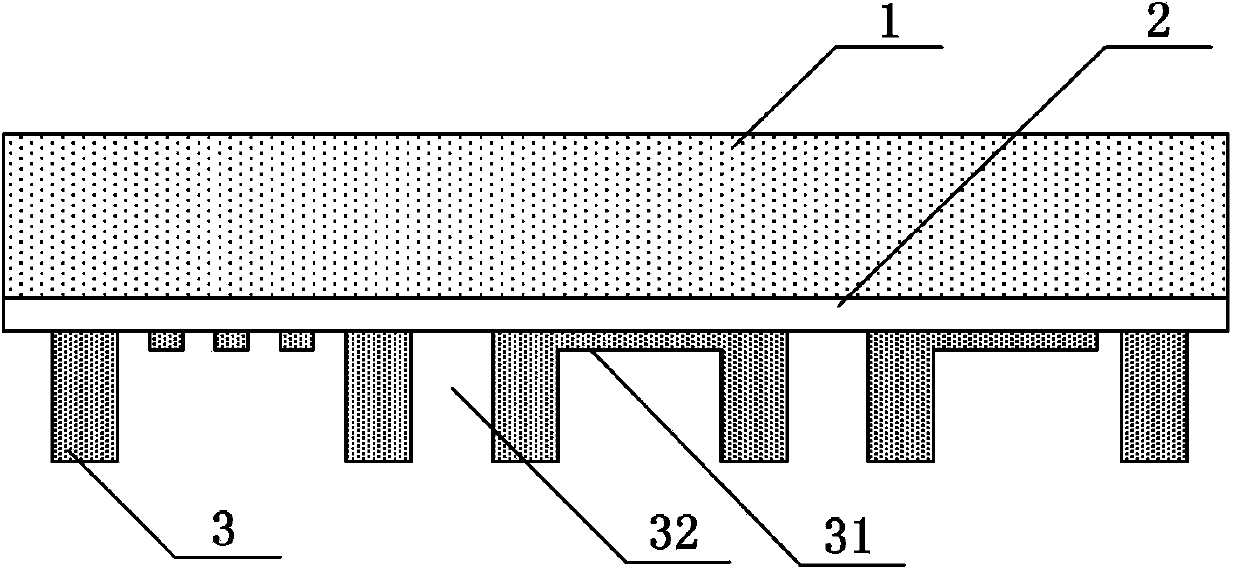

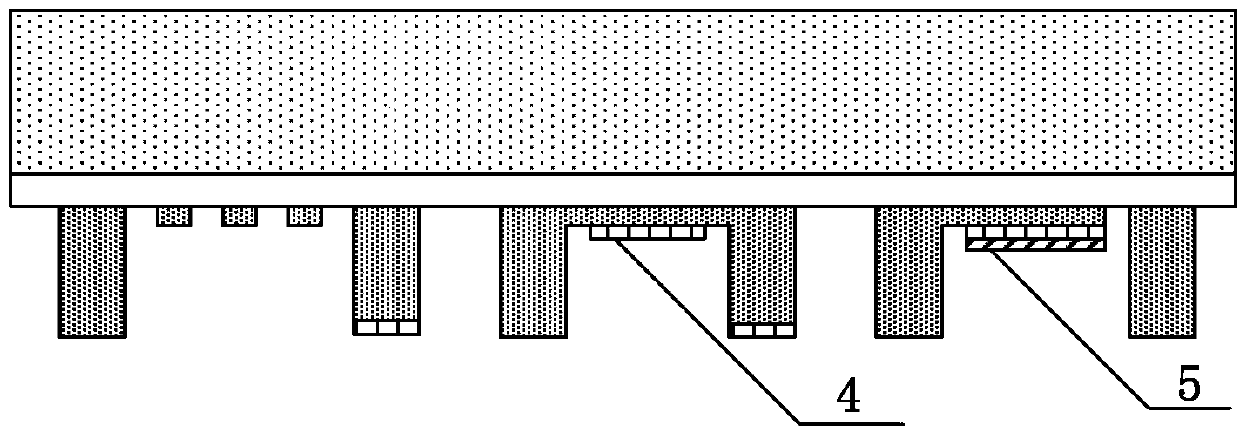

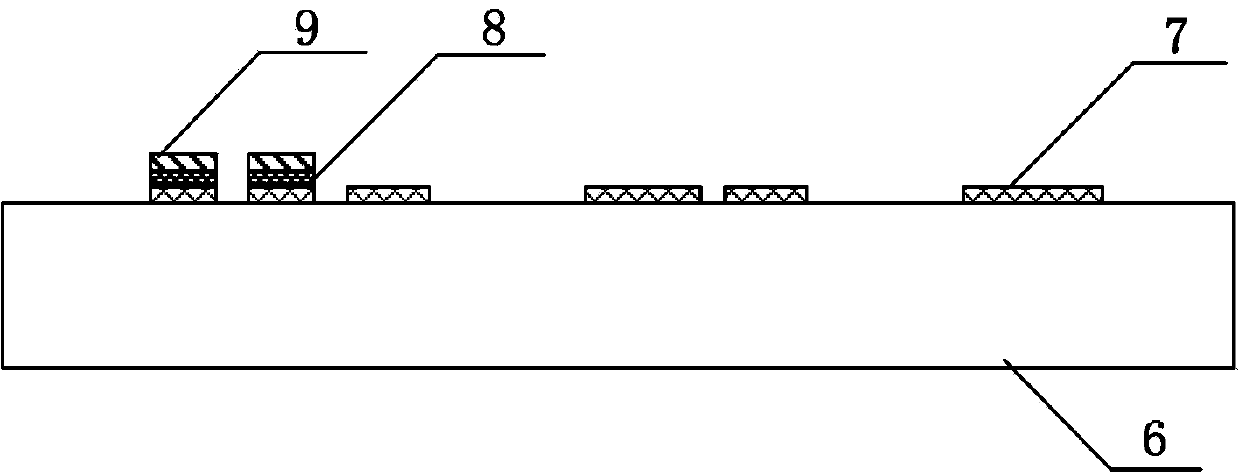

[0021] An integrated manufacturing method for capacitive temperature, humidity and air pressure sensors based on silicon anodic bonding of SOI device layers. The method is realized based on SOI device layer silicon and glass substrate 6. The set substrate silicon 1, the buried oxide layer 2, and the device layer silicon 3 are composed. Using the combination of step-by-step deep silicon etching technology and SOI device layer silicon and glass anode bonding technology, the thin film structure, the flat large capacitance structure and the sealed cavity structure of the air pressure sensor and temperature sensor are prepared at the same time, and finally the humidity sensor and air pressure sensor are formed. Sensor and temperature sensor integrated structure. The method comprises the steps of:

[0022] Step 1), such as figure 1 As shown, the device layer silicon 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com