Method for detecting mercury content in polymeric material and sample processing method

A polymeric material and sample processing technology, applied in the preparation of test samples, analytical materials, measuring devices, etc., can solve the problems of high experimental cost, volatilization loss, mercury adsorption, etc., and achieve high accuracy by avoiding adsorption and volatilization loss , the effect of reducing the cost of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

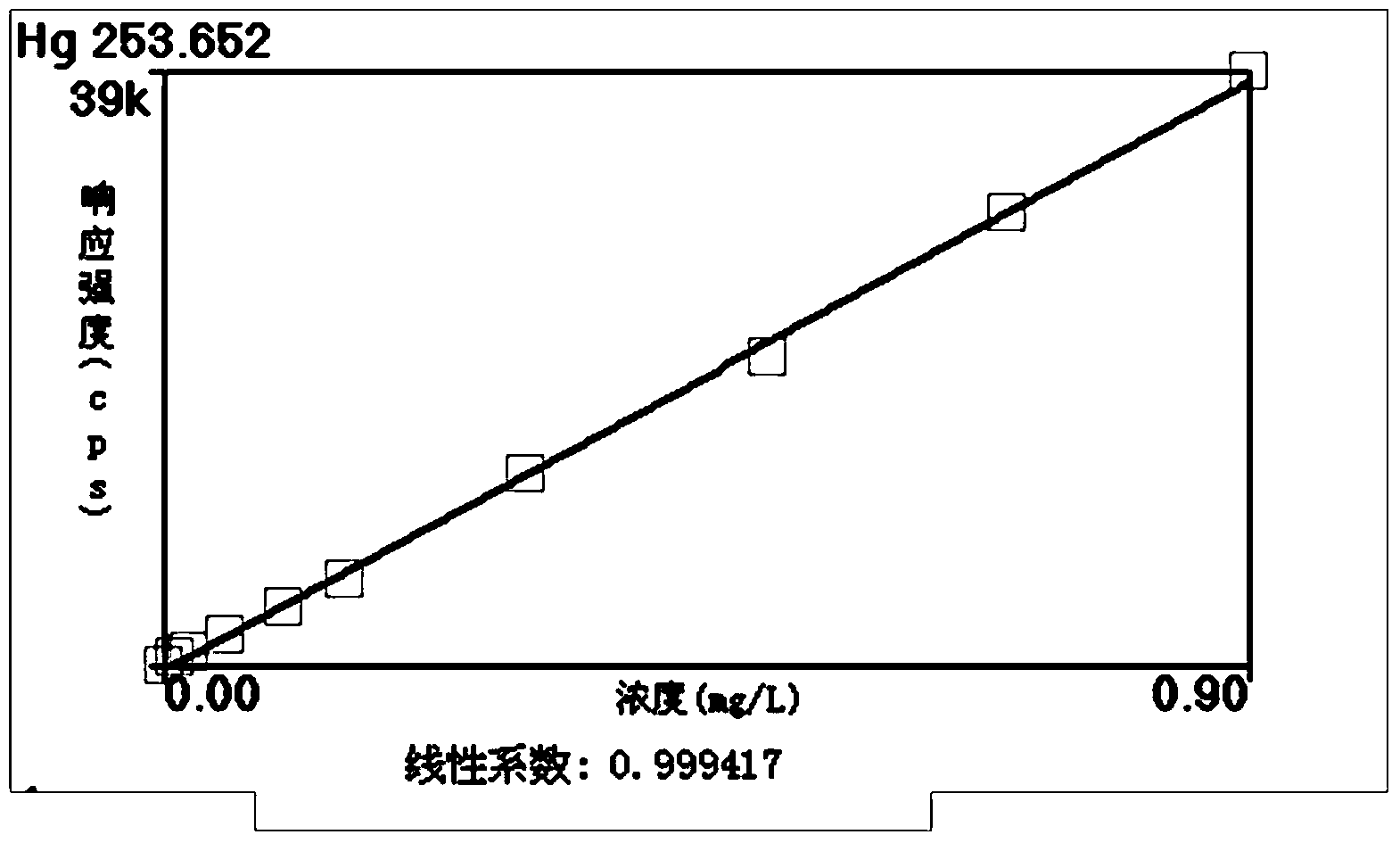

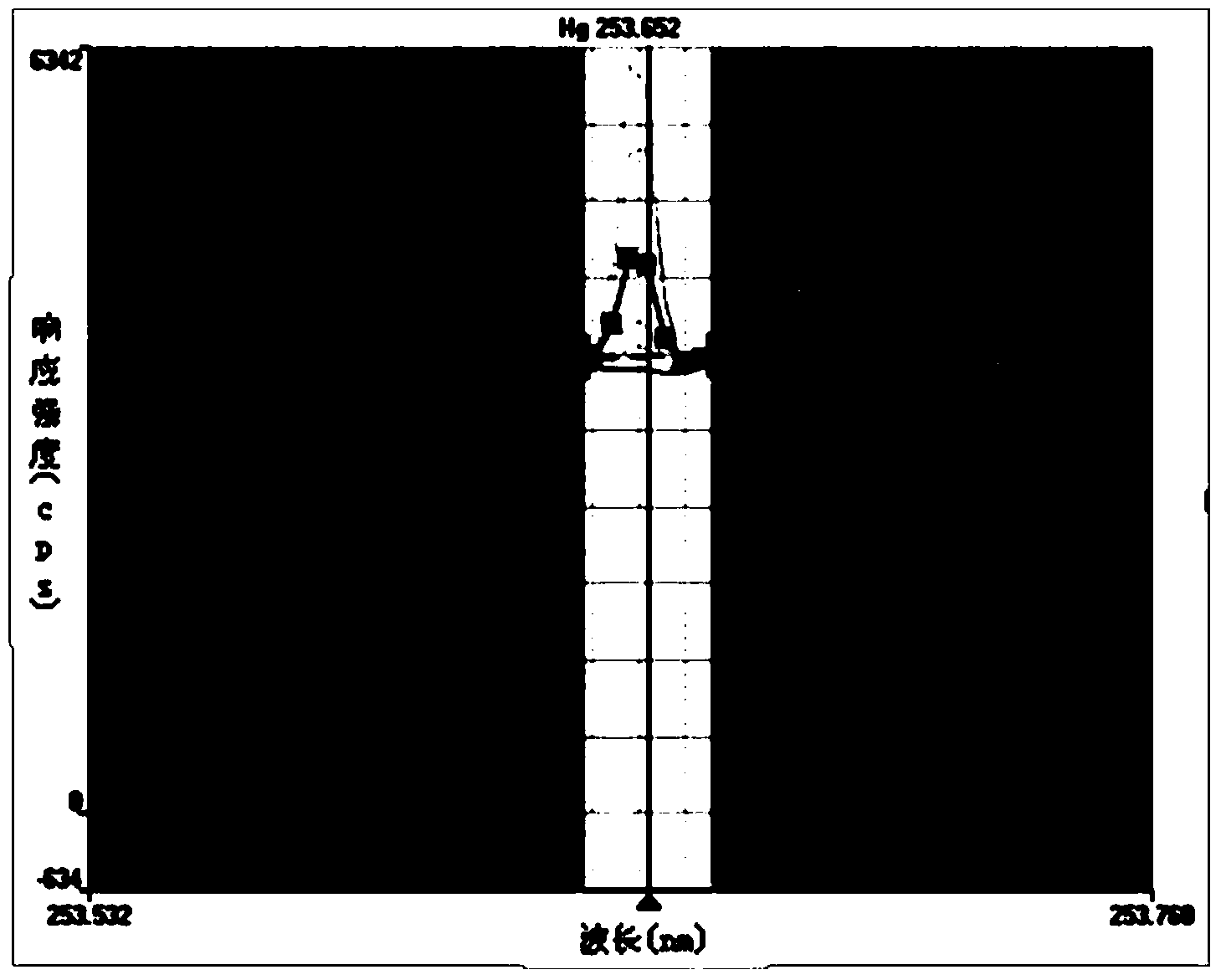

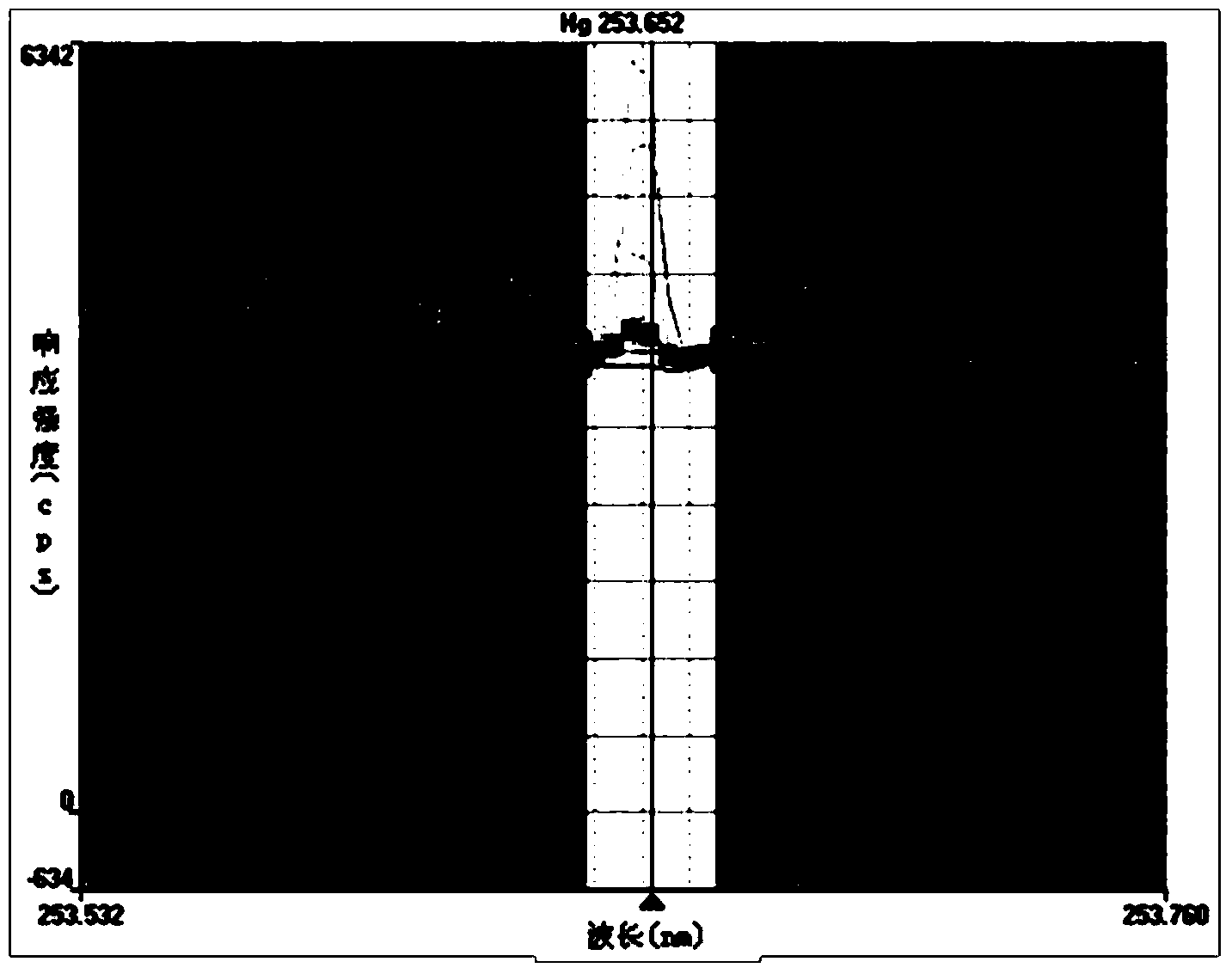

[0053] The mercury-containing polymer material sample described in this embodiment, ERM-EC681k is selected as a "blind sample" for detection, and the detection method of mercury content in the polymer material specifically includes the following steps:

[0054] a. Pretreatment of the sample, specifically including the following steps:

[0055] (1) Weigh 0.3g of ERM-EC681k into a beaker, add 5mL of concentrated sulfuric acid with a mass concentration of 98%, place the beaker on a heating plate, heat to 270°C-280°C and emit sulfuric acid fumes, the sample is digested and carbonized, Thus, all the mercury contained in the polymeric material forms mercury sulfate, and the organic components in it are completely carbonized into black substances;

[0056] (2) Add concentrated nitric acid with a mass concentration of 68% dropwise to the sample that has been carbonized in step (1) and emits sulfuric acid fumes until the black carbonized substance disappears completely, and a clear, co...

Embodiment 2

[0065] The mercury-containing polymer material sample described in this embodiment, ERM-EC680k is selected as a "blind sample" for detection, and the detection method of mercury content in the polymer material specifically includes the following steps:

[0066] a. Pretreatment of the sample, specifically including the following steps:

[0067] (1) Weigh 0.5g of ERM-EC680k into a beaker, add 5mL of concentrated sulfuric acid with a mass concentration of 98%, place the beaker on a heating plate, heat it to 270°C-280°C and emit sulfuric acid fumes, the sample is decomposed and carbonized, Thus, all the mercury contained in the polymeric material forms mercury sulfate, and the organic components in it are completely carbonized into black substances;

[0068] (2) Add concentrated nitric acid with a mass concentration of 65% dropwise to the sample that has been carbonized in step (1) and emits sulfuric acid fumes until the black carbonized substance disappears completely, and a clea...

Embodiment 3

[0075] The mercury-containing polymer material sample described in this embodiment, BW3079 is selected as a "blind sample" for detection, and the method for detecting mercury content in the polymer material specifically includes the following steps:

[0076] a. Pretreatment of the sample, specifically including the following steps:

[0077] (1) Weigh 0.2g of BW3079 into a beaker, add 3mL of concentrated sulfuric acid with a mass concentration of 98%, place the beaker on a heating plate, and heat it to 270°C-280°C to emit sulfuric acid fumes. The sample is decomposed and carbonized, thereby polymerizing the material All the mercury contained in it will generate mercuric sulfate, and the organic components in it will be completely carbonized into black substances;

[0078] (2) Add concentrated nitric acid with a mass concentration of 68% dropwise to the sample that has been carbonized in step (1) and emits sulfuric acid fumes until the black carbonized substance disappears compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com