Method for preparing lithium-enriched manganese-based anode material of nano-oxide-coated lithium ion battery

A nano-oxide, lithium-rich manganese-based technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve problems such as poor controllability and complex coating process, and achieve improved rate performance, low irreversible capacity, and rate performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

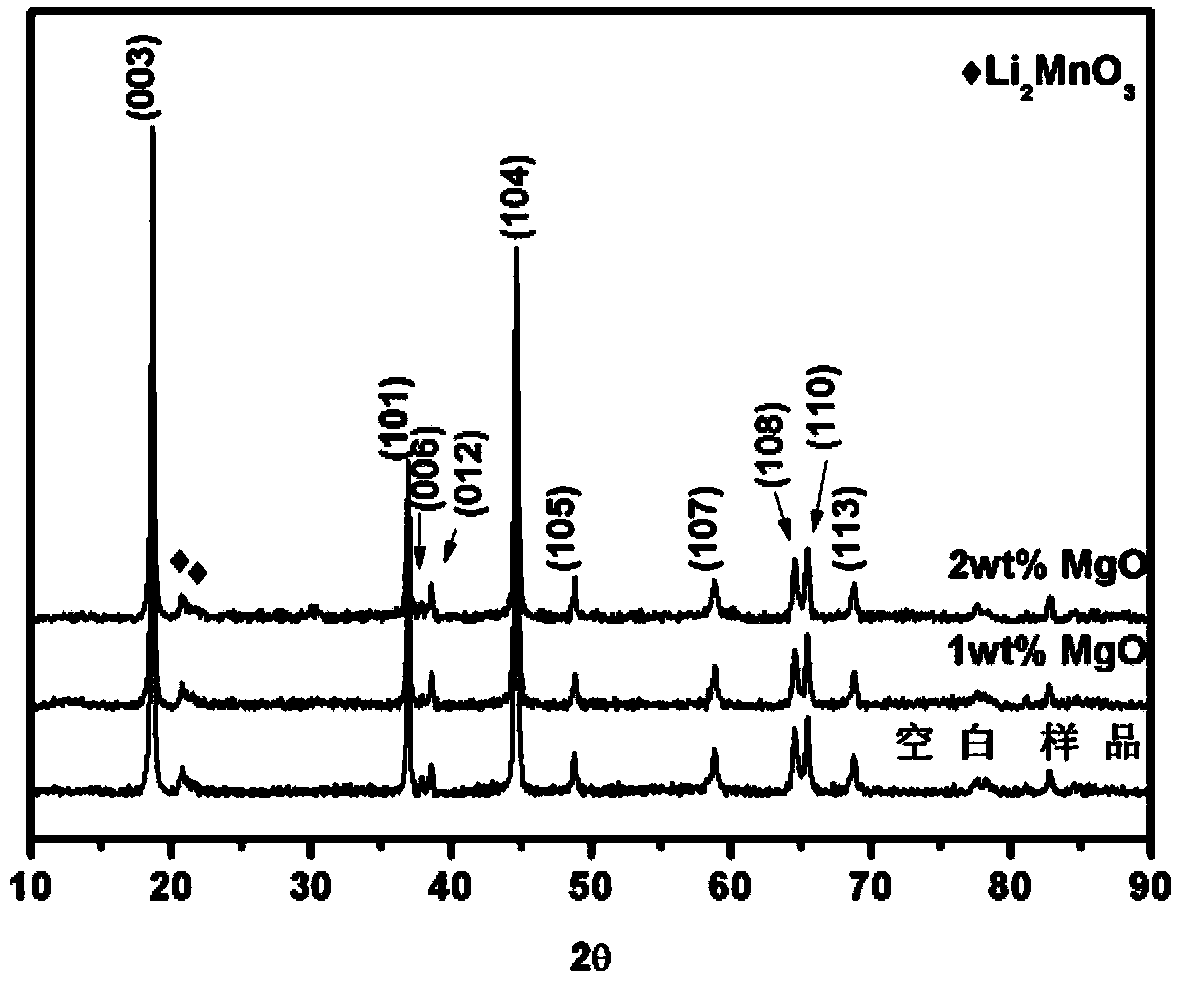

[0031] 1) Preparation of lithium-rich cathode material Li 1.2 mn 0.6 Ni 0.2 o 2 :

[0032] Weigh NiSO according to the molar ratio Mn:Ni=0.6:0.2 4 ·6H 2O and MnSO 4 ·H 2 O, prepared into a solution A with a metal ion concentration of 2mol / L; then press the metal ion and OH - Weigh NaOH with a molar ratio of 1:2, and prepare a NaOH solution with a concentration of 4mol / L; according to the concentration of ammonia water in the solution after mixing is 0.25mol / L, add an appropriate amount of ammonia water to the prepared NaOH solution, mix well and record it as a solution B: Slowly add solutions A and B into the reactor at the same time at the same rate, control the pH value of the reaction process to be 11.6-11.8, the temperature is 60°C, and the stirring speed is 500 rpm. After the reaction is complete, age for 6 hours. Then suction filter, wash, and dry to obtain nickel-manganese hydroxide precursor powder; sinter the prepared precursor powder at 500°C for 6 hours to c...

Embodiment 2

[0038] 1) Preparation of lithium-rich cathode material Li 1.2 mn 0.6 Ni 0.2 o 2 , the steps are the same as step 1 of Example 1).

[0039] 2) Weigh 0.02g of nano-magnesium oxide and 9.98g of lithium-rich manganese-based cathode material Li 1.2 mn 0.6 Ni 0.2 o 2 , put in a ball mill, add 50ml of ethanol, and carry out ball milling and mixing, the rotating speed is 600r / min, and the ball milling time is 5h. The mixture was dried at 120°C for 20h, placed at 900°C for 5h, the heating and cooling rate was controlled at 5°C / min, and ground to prepare 2wt% nano-magnesium oxide-coated Li 1.2 mn 0.6 Ni 0.2 o 2 .

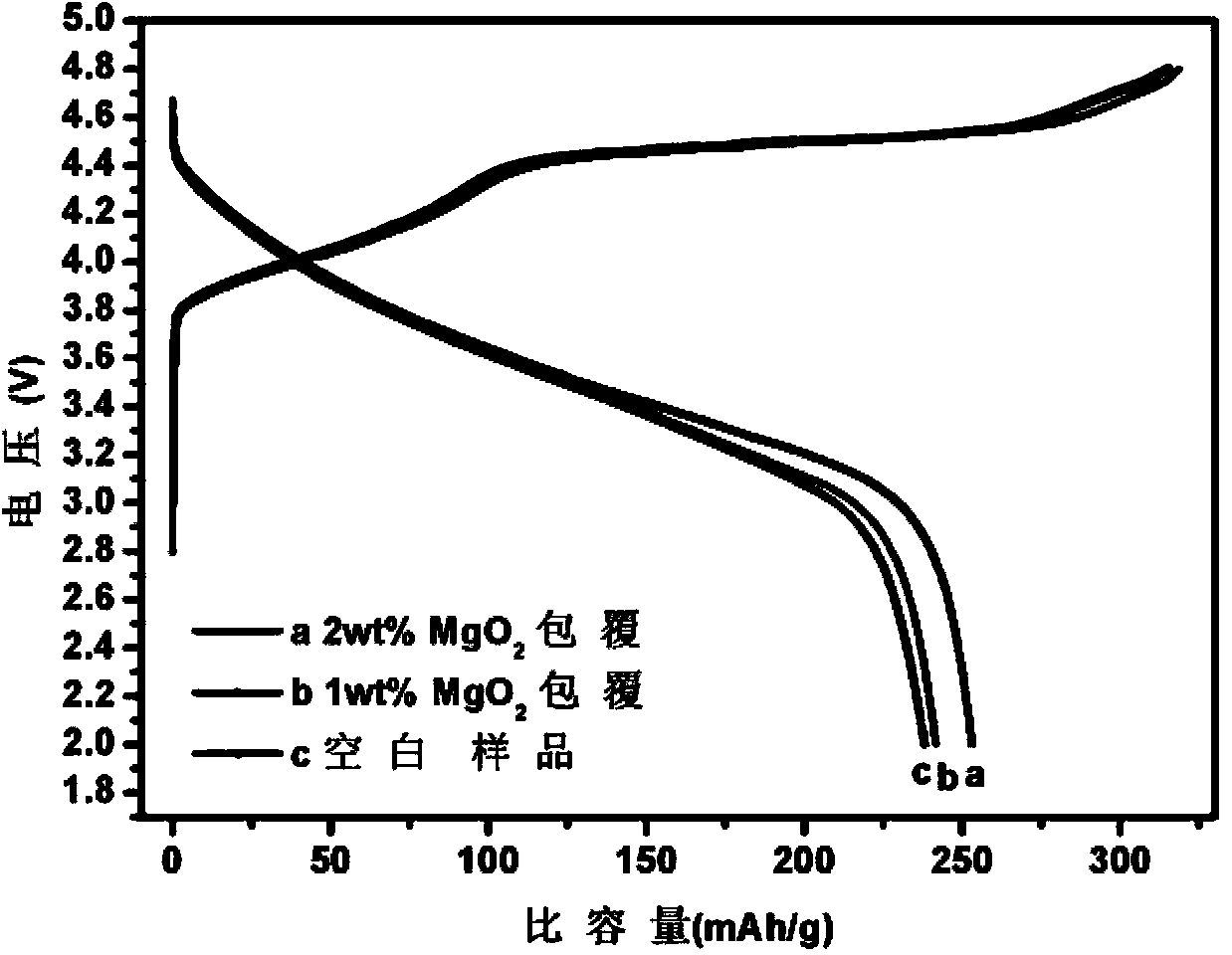

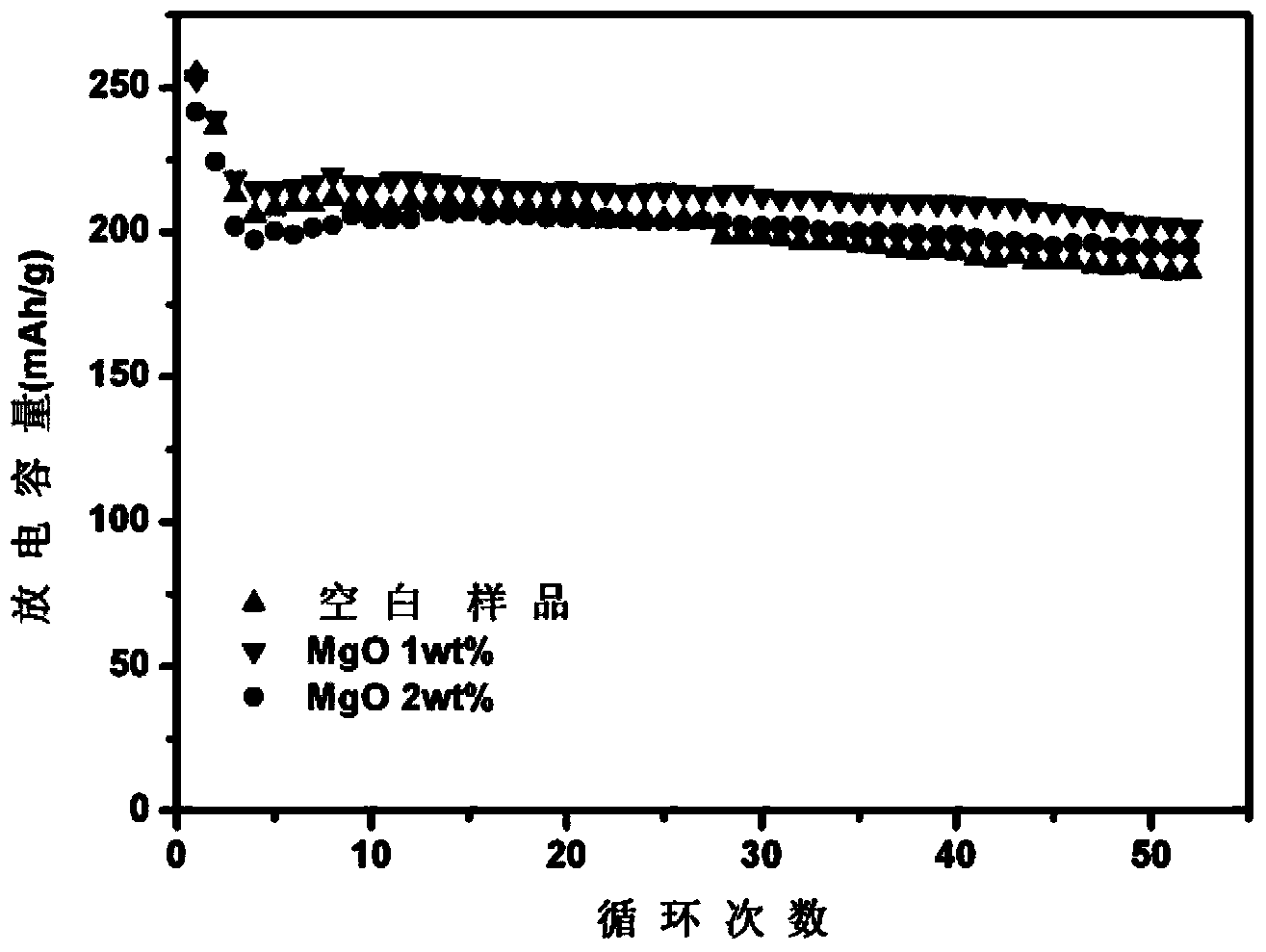

[0040] 2wt% MgO-coated sample was used as the positive electrode to form a button battery for testing. figure 2 with image 3 Compared with the electrochemical performance of uncoated samples, the first charge and discharge capacities of 2wt% coated samples were 314.5mAh / g and 241.7mAh / g respectively, and the first efficiency was 76.8%, which was significantly i...

Embodiment 3

[0042] 1) Preparation of lithium-rich cathode material Li 1.2 mn 0.6 Ni 0.2 o 2 , the steps are the same as step 1 of Example 1).

[0043] 2) Weigh 10g of nano-titanium oxide and 990g of lithium-rich manganese-based cathode material Li 1.2 mn 0.6 Ni 0.2 o 2 , placed in a high-speed mixer for high-speed mixing, the rotating speed is 5000r / min, and the mixing time is 3h. Then control the heating rate at 5°C / min, raise the temperature to 800°C, sinter at a constant temperature for 5 hours, then cool down to room temperature at 5°C / min, and grind to prepare nano-titanium oxide-coated Li 1.2 mn 0.6 Ni 0.2 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com