Manufacturing technology of suspending agent with strong spray-drift prevention function

A manufacturing technology and anti-drift agent technology, applied in the field of pesticides, can solve the problems of smaller droplet granules and aggravated drift, etc., and achieve the effects of low product cost, simple process and convenient purchase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 : 24% tebufenozide anti-spray drift suspension.

[0025] First, 60% of methylated soybean oil, 30% of polyvinyl acetate milk, 5% of urea-formaldehyde resin, 5% of 500# emulsifier, and 5% of 602 emulsifier are mixed and stirred evenly to make a composite anti-spray and drift agent, and then according to the quality Percent tebufenozide 24%, dispersant alkyl polyoxyethylene ether sulfonate 5%, wetting agent nonylphenol polyoxyethylene ether 1%, aluminum magnesium silicate 1.5%, xanthan gum 0.15%, antifreeze Ethylene glycol 5%, defoamer organic silicone 0.4%, water added to 100%. After mixing evenly, sand mill to the qualified particle size. Finally, add the mixed compound anti-spray and drift agent into the sanded tebufenozide suspending agent in an amount of 20%. Finally, it will be homogeneously sheared at a high speed with a thickener, etc. Serve.

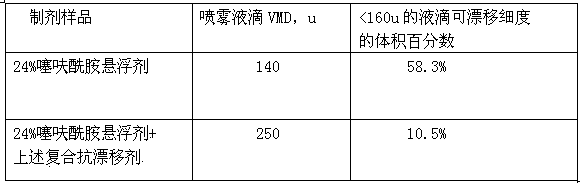

[0026] The spraying performance test of the final suspending agent is carried out. The nozzle is used to spr...

Embodiment 2

[0030] Example 2 : 30% quinclorac sustained-release suspension concentrate.

[0031] First, mix and stir 80% of methyl ester tea seed oil, 10% of polyacrylamide, 3% of urea-formaldehyde resin, 6% of 1601# emulsifier, and 4% of 33# emulsifier to make a composite anti-spray drift agent, and then press the quality Percentage 30% quinclorac, quinclorac 30%, dispersant polycarboxylate 4.5%, wetting agent wetting penetrant T 1%, aluminum magnesium silicate 1%, xanthan gum 0.2%, antifreeze Ethylene glycol 5%, defoamer organic silicone 0.4%, water added to 100%. After mixing evenly, sand mill to the qualified particle size, and finally add the mixed compound anti-spray and drift agent in an amount of 20% to the sand-milled quinclorac suspension, and finally, together with the thickener, etc., high-speed homogeneous shear Serve evenly. Carry out spraying performance test according to the method in example 1, control agent is the 30% quinclorac suspension concentrate that does not a...

Embodiment 3

[0034] Example 3 : 15% mesotrione suspension concentrate.

[0035] First, 70% of methyl esterified peanut oil, 20% of epoxy resin modified styrene-acrylic emulsion, 5% of urea-formaldehyde resin 700# emulsifier, and 5% of 1601 emulsifier were mixed and stirred evenly to make a composite anti-spray drift agent, and then Mesotrione 15% by mass, dispersant alkylnaphthalene formaldehyde condensate sulfonate 3.5%, fatty alcohol polyoxyethylene ether 1%, aluminum magnesium silicate 1.7%, xanthan gum 0.1%, antifreeze agent ethylene glycol Alcohol 5%, defoamer organic silicone 0.4%, water added to 100%. After mixing evenly, sand mill to the qualified particle size, and finally add the mixed compound anti-spray and drift agent into the sanded mesotrione suspending agent in an amount of 20%, and finally, together with the thickener, etc., shear at high speed and homogeneously Serve evenly. Spray performance test was carried out according to the method in Example 1, and the control a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com