Hollow molecular sieve fiber and preparation method thereof

A molecular sieve and solid fiber technology, applied in the direction of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc. Control the effective hollow structure morphology, the harsh requirements of molecular sieve components, etc., to achieve the effect of good reaction and separation performance, fast speed and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

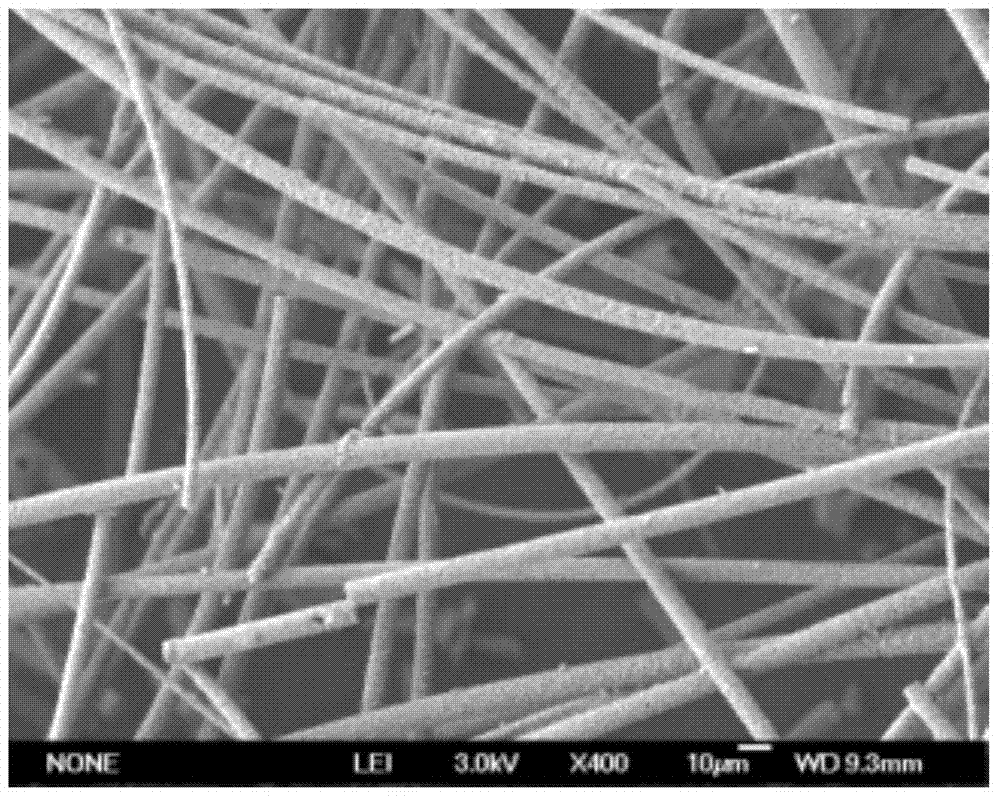

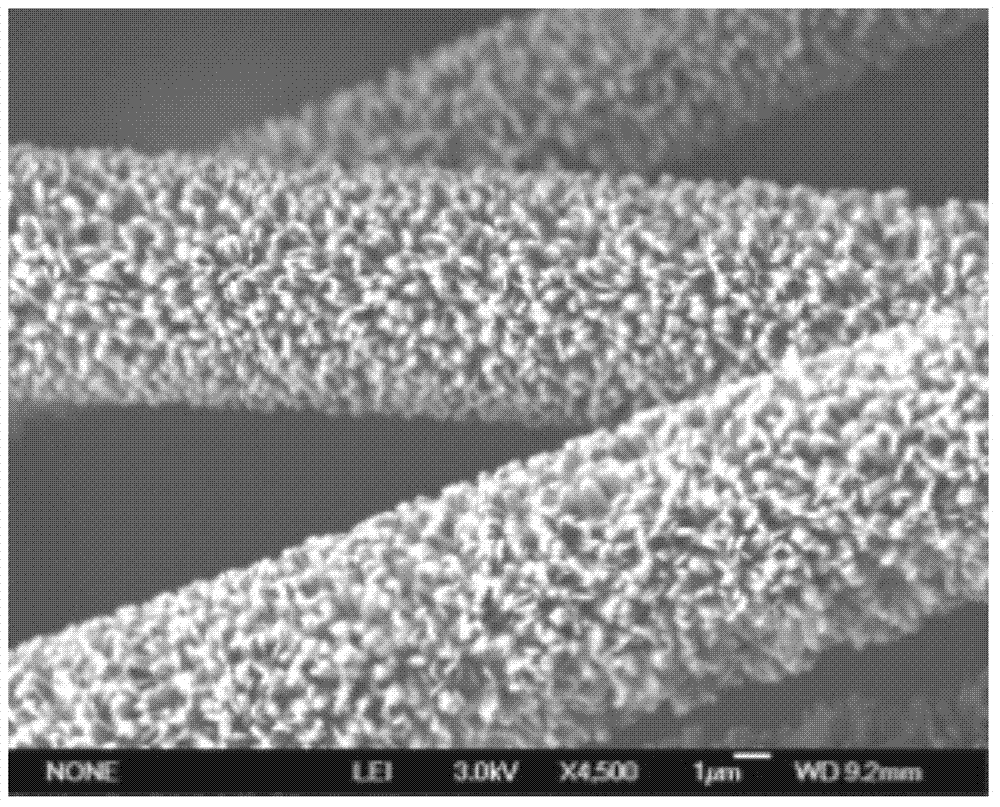

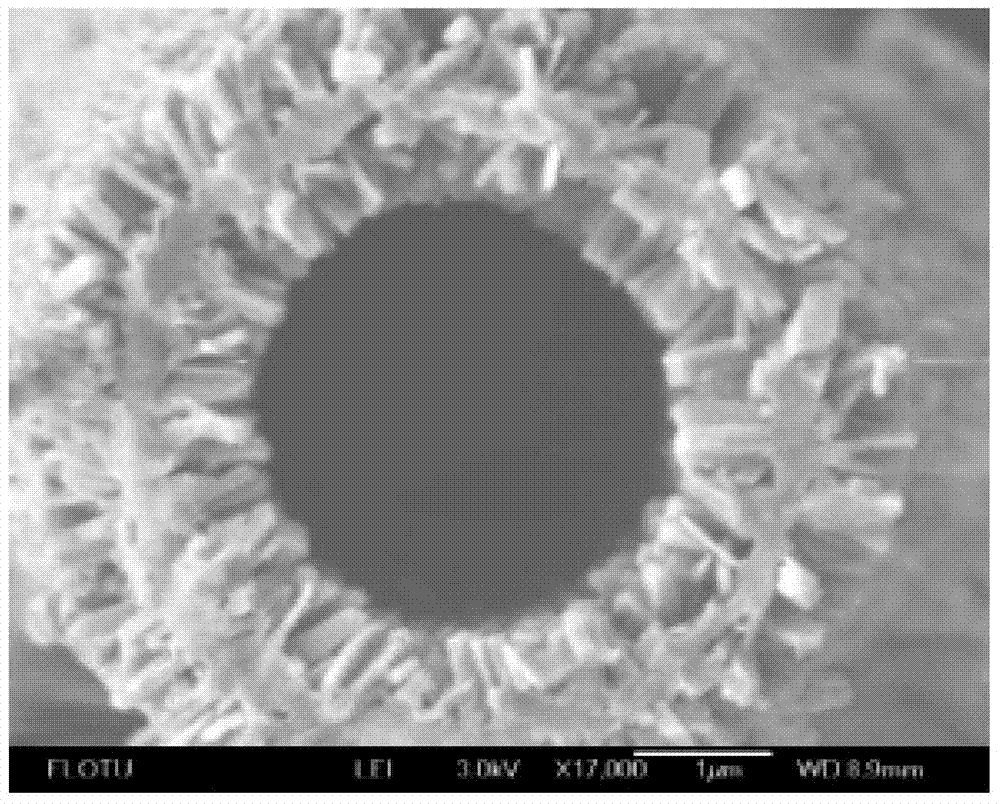

[0043] After mixing tetrapropylammonium hydroxide solution with a mass fraction of 25% and tetraethylorthosilicate at a mass ratio of 1:0.9 for 3 hours, pre-crystallized at 100°C for 48 hours to obtain ZSM-5 molecular sieve seed crystals. The total mass fraction of silicon and oxygen in the solid fiber containing silicon and oxygen elements is 100%, the outer diameter is 8 μm, and the aspect ratio is 20:1 (hereinafter referred to as the solid fiber). The ZSM-5 molecular sieve crystal seed, the solid fiber Mix with sodium metaaluminate at a molar ratio of 100:10:10 for 3 hours to make the ZSM-5 molecular sieve seeds evenly adhere to the surface of the solid fiber, then remove it and dry at 120°C for 0.2 hours to obtain a dry powder .

[0044] Place a support with a height of 3 times the diameter of the hydrothermal kettle in a hydrothermal kettle with a polytetrafluoroethylene liner, and pour water into it to control the amount of water added to just submerge the bracket, place...

Embodiment 2

[0048] After mixing tetrapropylammonium hydroxide solution with a mass fraction of 50% and tetraethylorthosilicate at a mass ratio of 3:1 for 1 hour, pre-crystallized at 120°C for 72 hours to obtain ZSM-5 molecular sieve seed crystals. The total mass fraction of silicon and oxygen in the solid fiber containing silicon and oxygen elements is 80% (other components are sodium and calcium elements), the outer diameter is 0.5 μm, and the aspect ratio is 1000:1 (hereinafter referred to as solid fiber). Mix the ZSM-5 molecular sieve crystal seed, solid fiber and sodium metaaluminate at a molar ratio of 20:5:0.5 for 0.3 hours, so that the ZSM-5 seed crystal evenly adheres to the surface of the solid fiber, then pull it out, and Dry at 100°C for 3 hours to obtain dry powder.

[0049] Place a support with a height of 0.3 times the diameter of the hydrothermal kettle in a hydrothermal kettle with a polytetrafluoroethylene liner, and pour in water, control the amount of water added to jus...

Embodiment 3

[0052] After mixing tetrapropylammonium hydroxide solution with a mass fraction of 40% and tetraethylorthosilicate at a mass ratio of 1:1 for 3 hours, pre-crystallized at 105°C for 72 hours to obtain ZSM-5 molecular sieve seed crystals. The total mass fraction of silicon and oxygen in the solid fiber containing silicon and oxygen is 90% (others are potassium, aluminum, iron), the outer diameter is 2 μm, and the aspect ratio is 200:1 (hereinafter referred to as solid fiber). Mix the ZSM-5 molecular sieve crystal seed, solid fiber and sodium metaaluminate at a molar ratio of 10:5:0.1 for 1 hour, so that the ZSM-5 molecular sieve seed crystal evenly adheres to the surface of the solid fiber, and then remove it , and dried at 110° C. for 1 hour to obtain dry powder.

[0053] Place a support with a height of 1 times the diameter of the hydrothermal kettle in a hydrothermal kettle with a polytetrafluoroethylene liner, and pour water, control the amount of water added to just submerg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com