High-efficiency suspended filler and preparation method thereof

A suspended filler, high-efficiency technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of easy deformation, long film hanging time, decreased material flexibility, etc. High, short film hanging time, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] High-efficiency suspended filler of the present invention, its preferred embodiment is:

[0027] The hydrophilic non-woven fabric comprises a hydrophilic fiber layer and a water-repellent polymer layer bonded together on a rigid support.

[0028] The rigid support is a plastic film or porous net, the hydrophilic fibers include plant fibers and / or hydrophilic polymer fibers, and the water-repellent polymer includes polyethylene and / or polypropylene.

[0029] The height dimension of the ribs of the porous network is greater than the thickness dimension.

[0030] The preparation method of the above-mentioned high-efficiency suspended filler of the present invention, its preferred embodiment comprises steps:

[0031] First, the water-repellent polymer is sprayed from the high-temperature melt nozzle after melting, forming fibers attached to the surface of the rigid support, and at the same time, the hydrophilic fiber is sprayed from the hydrophilic fiber nozzle and evenly ...

specific Embodiment

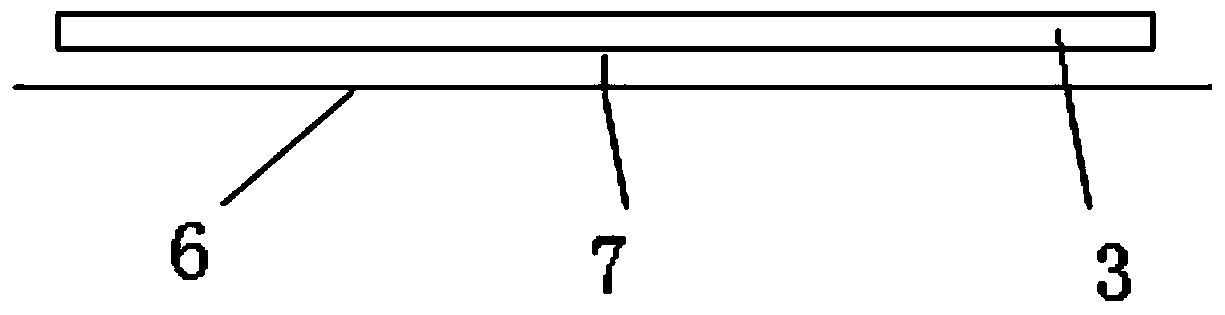

[0038] Such as figure 1 As shown, the basic material structure of the high-efficiency suspended filler of the present invention includes a hydrophilic non-woven fabric 6, a rigid support 3, a connection point 7, and the like.

[0039] The non-woven fabric is composed of a large number of fibers and lacks the rigidity of the plastic sheet. In the present invention, the soft hydrophilic fiber cloth is supported by a rigid plastic film or net so that it has the mechanical strength of the plastic sheet. The hydrophilic non-woven fabric and the rigid support can be fixed by methods such as fusion connection.

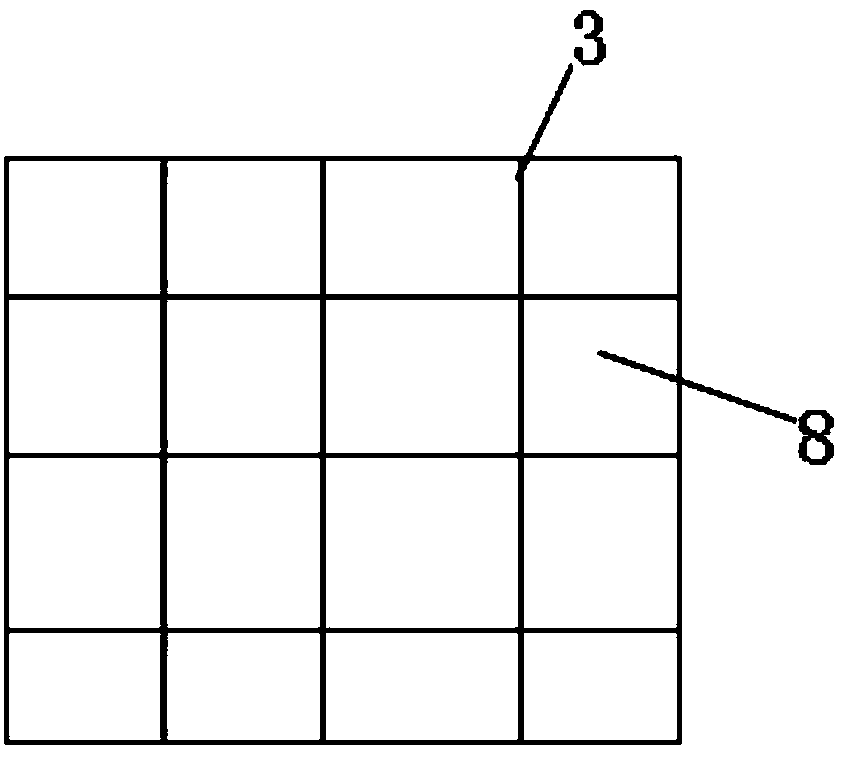

[0040] Such as figure 2 As shown, the rigid support is a plastic film or a porous net, and the height of the ribs of this porous net is greater than the thickness. This structure saves the use of materials and increases the mechanical strength of the support material. The pore size of the rigid support porous network can be changed according to different needs. When the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com