Heavy oil thermal conversion and green coke gasification method and integrated device

A combined device, thermal conversion technology, applied in non-catalytic thermal cracking, granular/powder fuel gasification, cracking, etc., can solve the problems of high temperature and unfavorable light oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

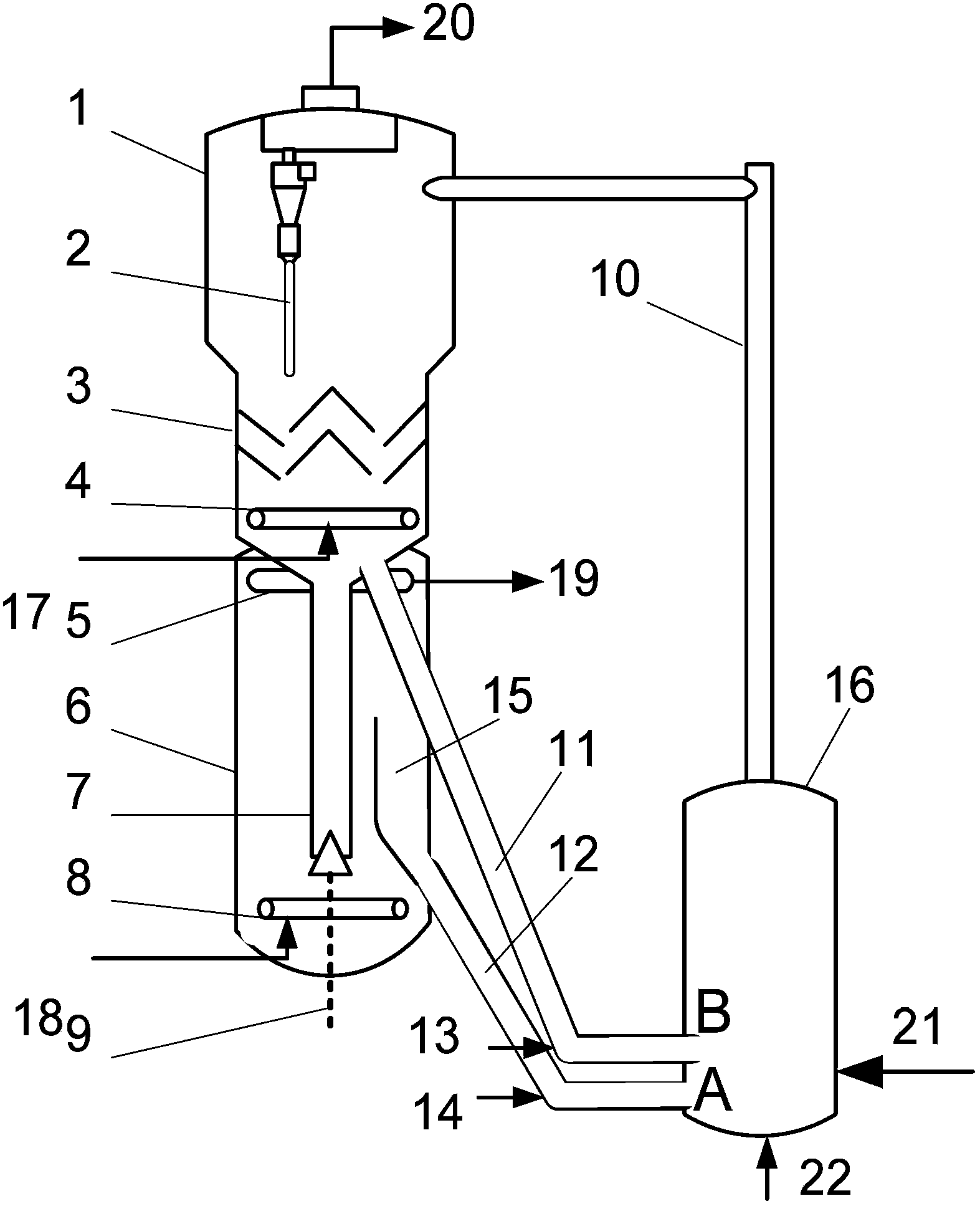

[0039] use figure 1 In the device shown, the raw material oil is vacuum residue oil, the residual carbon is 9wt%, and the heat carrier is completely inert non-porous silica particles with a particle size range of 40-120 μm. The vacuum residue is preheated to 300°C and enters the fast bed 16, where it contacts and reacts with the fluidized silicon oxide particles. The temperature in the bed is maintained at 520°C, and the apparent gas velocity is 1.1-1.8m / s. The superficial gas velocity is 3.5-5m / s, the silicon oxide and oil and gas enter the settler 1, and the oil and gas 20 are produced at the top. The silicon oxide particles are removed by the stripper 3 and the residual oil and gas are removed all the way through the inclined pipe 11 to return to the fast bed 16, and all the way through the vertical Pipe 7 enters the gasification reactor 6, and the bottom of the gasification reactor is fed with a mixed gas of oxygen and water vapor, with a volume ratio of 1:2.5, and the syn...

Embodiment 2

[0041] use figure 1 In the device shown, the raw material oil is hard pitch, the residual carbon is 27wt%, and the heat carrier is completely inert non-porous silica particles with a particle size range of 40-120 μm. The raw material is preheated to 380°C and enters the fast bed 16, where it contacts and reacts with the fluidized silicon oxide particles. The temperature in the bed is maintained at 560°C, the apparent gas velocity is 1.4-1.6m / s, and the apparent gas in the riser 10 is maintained. At a speed of 4-6m / s, the silicon oxide and oil and gas enter the settler 1, and the oil and gas 20 are produced at the top. The silicon oxide particles are removed by the stripper 3 and the residual oil and gas are removed all the way through the inclined pipe 11. Return to the fast bed 16, and enter through the standpipe 7 all the way. Gasification reactor 6, the bottom of the gasification reactor is fed with a mixed gas of oxygen and water vapor, with a volume ratio of 1:2.5, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com