Liquid-phase sintering method for preparing high-melting-point hard material particle dispersion-strengthened copper-based composite material and electromagnetic sintering device

A technology of hard material particles and copper-based composite materials, which is applied in the powder metallurgy preparation method and sintering device field of copper-based composite materials, can solve the problems of unsteady control of the production process, complicated process, and easy contamination of the composite material interface. Achieve the effect of low cost, simple process and increase effective viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, alumina powder is used as the high melting point hard material for dispersion strengthening, and copper alloy is used to prepare copper-containing powder to make Cu-Al 2 o 3 Powder metallurgy is carried out on the prefabricated powder round billet to prepare a dense high-strength copper-based composite material billet of copper alloy dispersion-strengthened by high-melting-point hard material particles.

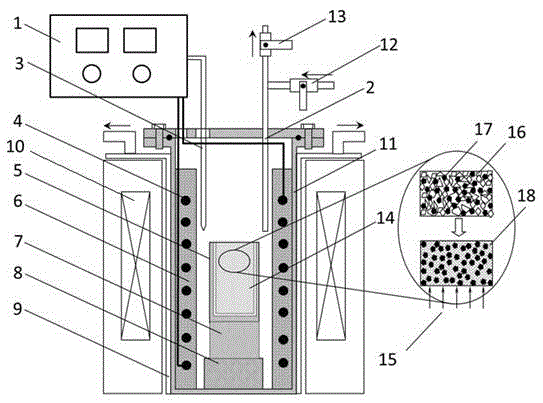

[0028] In this example, see figure 1 , the electromagnetic sintering device for the method of preparing high-melting-point hard material particles dispersion-strengthened copper-based composite material by liquid-phase sintering is composed of a heating and heat preservation device, an atmosphere control device and a constant magnetic field generating device 10, specifically:

[0029] The heating and heat preservation device is composed of a stainless steel furnace body 11, a crucible 5, a refractory fiber 6, a heating element 4, a temperature control...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035] In this example, the copper powder and micro-alumina powder prepared in the above-mentioned Example 1 are replaced with copper powder with dispersed distribution of nano-alumina prepared by the internal oxidation method, without powder mixing, and directly pressed into a compact, and then the above-mentioned In the same liquid-phase sintering process as in Example 1, the magnetic induction intensity is controlled to 16T, the liquid-phase sintering temperature is 1100°C, and the temperature is kept at 10 hours, then a high-strength and high-conductivity copper alloy billet with nano-alumina dispersion strengthening can also be prepared. Then, various nano-alumina dispersion-strengthened copper alloy rods, pipes, plates or wires can be prepared by conventional rolling and drawing processes, and have excellent strength and electrical conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com