Coke quality prediction method in coal silo mode

A prediction method and coke quality technology, applied in coke ovens, fuel oil testing, special data processing applications, etc., to achieve the effect of predicting and pre-controlling coke quality in advance and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and several preferred embodiments, but is not limited thereto.

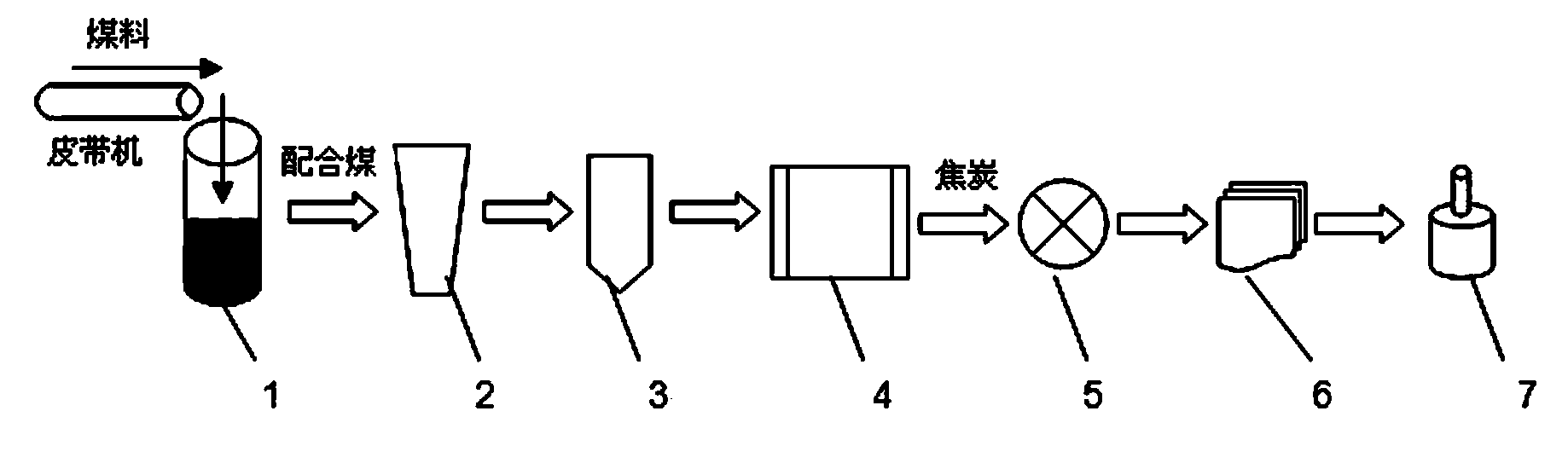

[0017] Concrete implementation steps of the present invention are as follows:

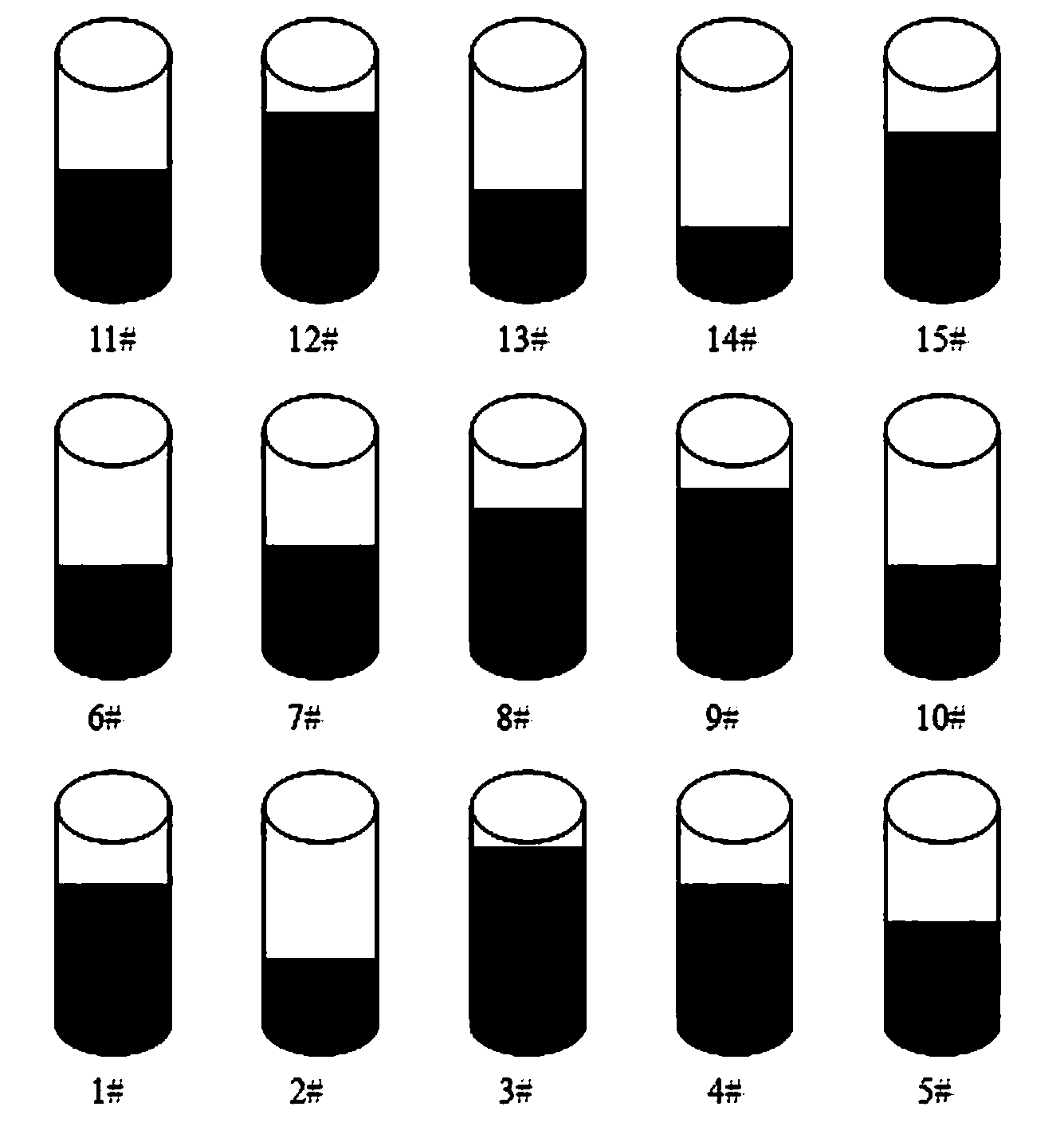

[0018] Step 1: Simulate the operation rules of batch materials in the coal silo, and establish a mathematical model based on the incoming coal index, proportioning scheme, pulverization index information, coke oven type, turnaround time, standard temperature, coke quenching method, and granulation method information ; Predict the coke conventional indicators and according to the manual entry of material information into the warehouse, the computer automatically collects the warehouse information, establishes columnar graphs and charts, real-time dynamic changes; predicts coke conventional indicators, including ash A, sulfur S, crushing strength M 40 , abrasion resistance M 10 , take the formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com