Aroma polyamide composite membrane with surface containing salicylaldehyde and quaternary ammonium salt and preparing method of aroma polyamide composite membrane

An aromatic polyamide and composite membrane technology, which is used in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Chlorine and oxygen stability of composite membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

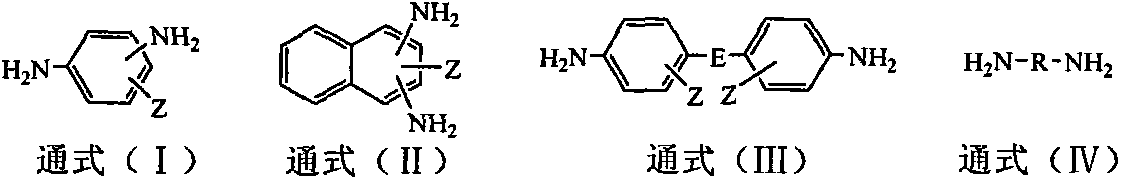

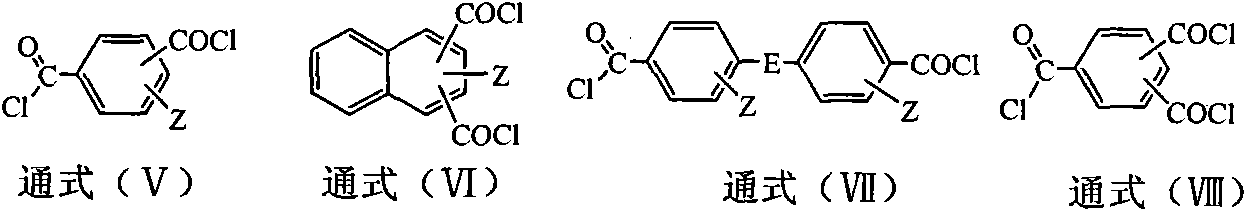

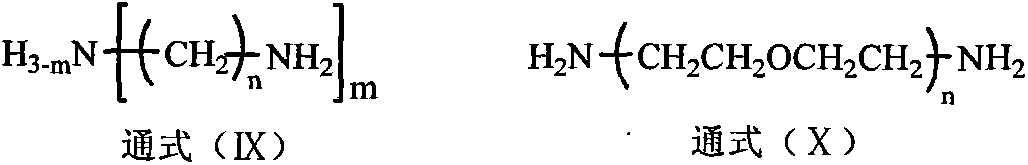

Method used

Image

Examples

Embodiment 1

[0062] Example 1 Preparation of aromatic polyamide / polysulfone composite membrane containing salicylaldehyde and quaternary ammonium salt on the surface

[0063] Step 1 Preparation of aromatic polyamide / polysulfone composite membrane containing acid chloride groups on the surface

[0064] Take the purified and dried polysulfone support membrane with a molecular weight cut-off of 20,000-50,000 and immerse it in a dichloromethane solution with a mass percent concentration of 0.5-15% m-phenylenediamine, immerse it at room temperature for 24 hours, take it out and air-dry it, and spray it at room temperature A dichloromethane solution containing isophthaloyl chloride, trimesoyl chloride and triethylamine with a concentration of 0.5-15% by mass, after reacting at room temperature for 0.2 hours, raising the temperature to 50-90°C and continuing the reaction for 2 hours , washed with acetone, and vacuum-dried to prepare an aromatic polyamide / polysulfone composite membrane containing ...

Embodiment 2

[0071] Example 2 Preparation of aromatic polyamide / polypropylene fiber non-woven composite membrane containing salicylaldehyde and quaternary ammonium salt on the surface

[0072] According to the method and operation steps of Example 1, the polysulfone support membrane in Step 1 of Example 1 was replaced with polypropylene non-woven fabric, and the aromatic polyamide / Polypropylene non-woven composite diaphragm (abbreviated as APA / PP-1-QAS composite diaphragm).

Embodiment 3

[0073] Example 3 Preparation of aromatic polyamide / cotton fiber filter paper composite membrane containing salicylaldehyde and quaternary ammonium salt on the surface

[0074] According to the method and operation steps of Example 1, the polysulfone support membrane in Step 1 of Example 1 is replaced with cotton fiber filter paper, and the ethylenediamine group in Step 2 is replaced with Diethylenetriamine, so that the surface contains salicylaldehyde Aromatic polyamide / cotton fiber filter paper composite membrane with quaternary ammonium salt (abbreviated as APA / FP-2-QAS composite membrane).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com