A kind of preparation method of high temperature microcrystalline bamboo charcoal

A technology of microcrystalline bamboo charcoal and high temperature, which is applied in the field of high-temperature microcrystalline bamboo charcoal and its preparation, can solve the problems of high refining temperature, restriction of comprehensive functions and wide applications of bamboo charcoal products, and low yield, and achieve the effect of increasing the far-infrared radiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

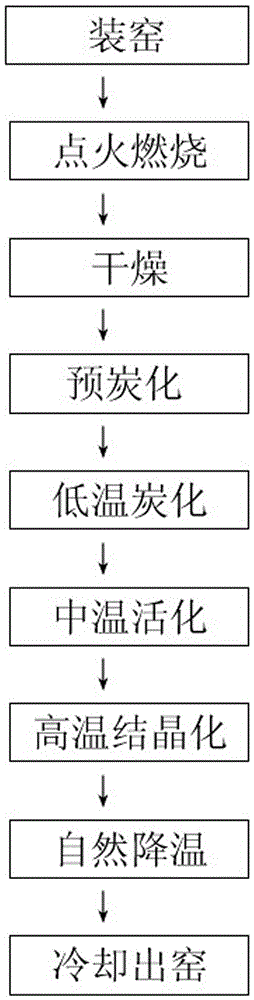

[0032] A preparation method of high-temperature microcrystalline bamboo charcoal, comprising the steps of:

[0033] (1) Put the bamboo raw material into the kiln from the feed port, and gradually dry the bamboo in the furnace with the heat of part of the bamboo combustion until it maintains spontaneous combustion;

[0034] (2) When the temperature in the furnace reaches 450°C, gradually reduce the smoke exhaust port and air inlet, and control the temperature of the kiln between 450-500°C to maintain the spontaneous combustion of bamboo and gradually carbonize;

[0035] (3) Adjust the air inlet and smoke exhaust port to raise the furnace temperature. When it rises to 850°C, send superheated steam from the water vapor and nitrogen gas supply pipes to activate the low-temperature bamboo charcoal. hold for 2 hours ;

[0036] (4) Slowly feed nitrogen gas from the water vapor and nitrogen gas supply pipes to make the medium-temperature bamboo charcoal in the furnace approach the s...

Embodiment 2

[0040] A preparation method of high-temperature microcrystalline bamboo charcoal, comprising the steps of:

[0041] (1) Put the bamboo raw material into the kiln from the feed port, and gradually dry the bamboo in the furnace with the heat of part of the bamboo combustion until it maintains spontaneous combustion;

[0042] (2) When the temperature in the furnace reaches 450°C, gradually reduce the smoke exhaust port and air inlet, and control the temperature of the kiln between 450-500°C to maintain the spontaneous combustion of bamboo and gradually carbonize;

[0043] (3) Adjust the air inlet and smoke exhaust port to raise the furnace temperature. When it rises to 850°C, send superheated steam from the water vapor and nitrogen gas supply pipes to activate the low-temperature bamboo charcoal. keep for 4 hours ;

[0044] (4) Slowly feed nitrogen gas from the water vapor and nitrogen gas supply pipes to make the medium-temperature bamboo charcoal in the furnace approach the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com