Electric heating printing ink as well as preparation method and application thereof

A technology of electrothermal ink and graphene, applied in the direction of ink, application, electrothermal device, etc., can solve the problems of poor electrothermal performance, low solid content, heat resistance of easily agglomerated resin, etc., achieve high electrothermal radiation conversion efficiency and reduce contact resistance , Increase the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

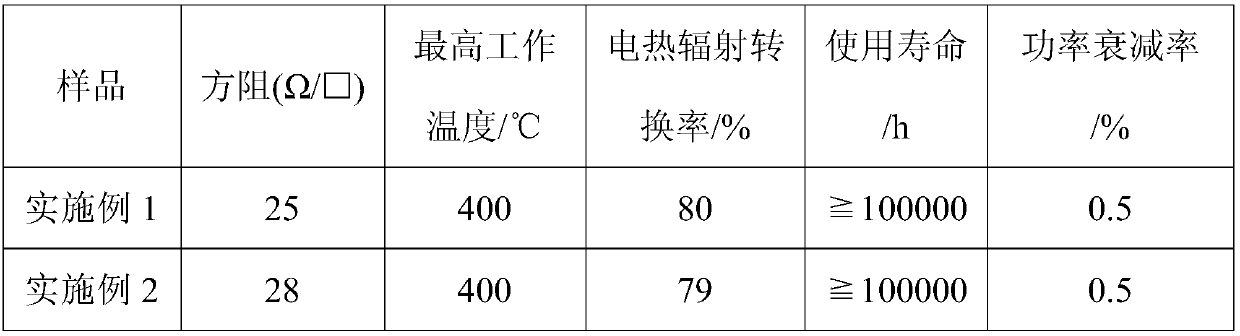

Embodiment 1

[0054] An electric heating ink is composed of 10 parts of conductive filler, 9 parts of dispersant, 40 parts of resin, 40 parts of solvent and 1 part of auxiliary agent.

[0055] Wherein, conductive filler is the conductive carbon black that contains graphene composition, and graphene contains Fe, Si and Al element, and the carbon-oxygen mass ratio of graphene is 40:1, and conductive carbon black accounts for 80wt% of conductive filler, and Fe, Si and Al Al element accounts for 1wt% of the conductive filler. The dispersant is Deqian 9200; the resin is a combination of silicone resin and phenolic resin with a mass ratio of 8:1; the solvent is a combination of DBE:cyclohexanone=4:1 (mass ratio); the auxiliary agent is Levaslip 468:Defom 6800 = 1:1 combination.

[0056] The preparation method is as follows:

[0057] (1) Graphene containing functional elements, conductive carbon black, dispersant and solvent were mixed for 1 hour, then ball milled for 4 hours to obtain a composi...

Embodiment 2-3

[0060] The only difference from Example 1 is that in this example, the carbon to oxygen mass ratio of graphene is 20:1 (Example 2) and 60:1 (Example 3).

Embodiment 4-8

[0062] The only difference with Example 1 is that in this example, conductive carbon black accounts for 75wt% (Example 4), 90wt% (Example 5), 50wt% (Example 6), and 40wt% (Example 4) of the conductive filler. Example 7), 97wt% (Example 8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com