Sanitary ceramics with anti-scaling function and preparation method thereof

A technology of sanitary ceramics and functions, which is applied in the field of sanitary ceramics with anti-scaling function, which can solve the problems of poor anti-fouling, no inhibition of scale formation, and unguaranteed antibacterial effect, etc., and achieve the effect of anti-scaling function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Sanitary ceramics with anti-scaling function include the following components (% by weight): 9 calcite, 6 dolomite, 2 talc, 31 feldspar, 26 quartz, 2 kaolin, 11 zircon, 1 barium carbonate, 1 burnt zinc oxide, 7wt% copper-loaded medical stone (copper loading) 2, 3wt% cerium oxide doped tourmaline 8, sepiolite mineral nanofiber 1.

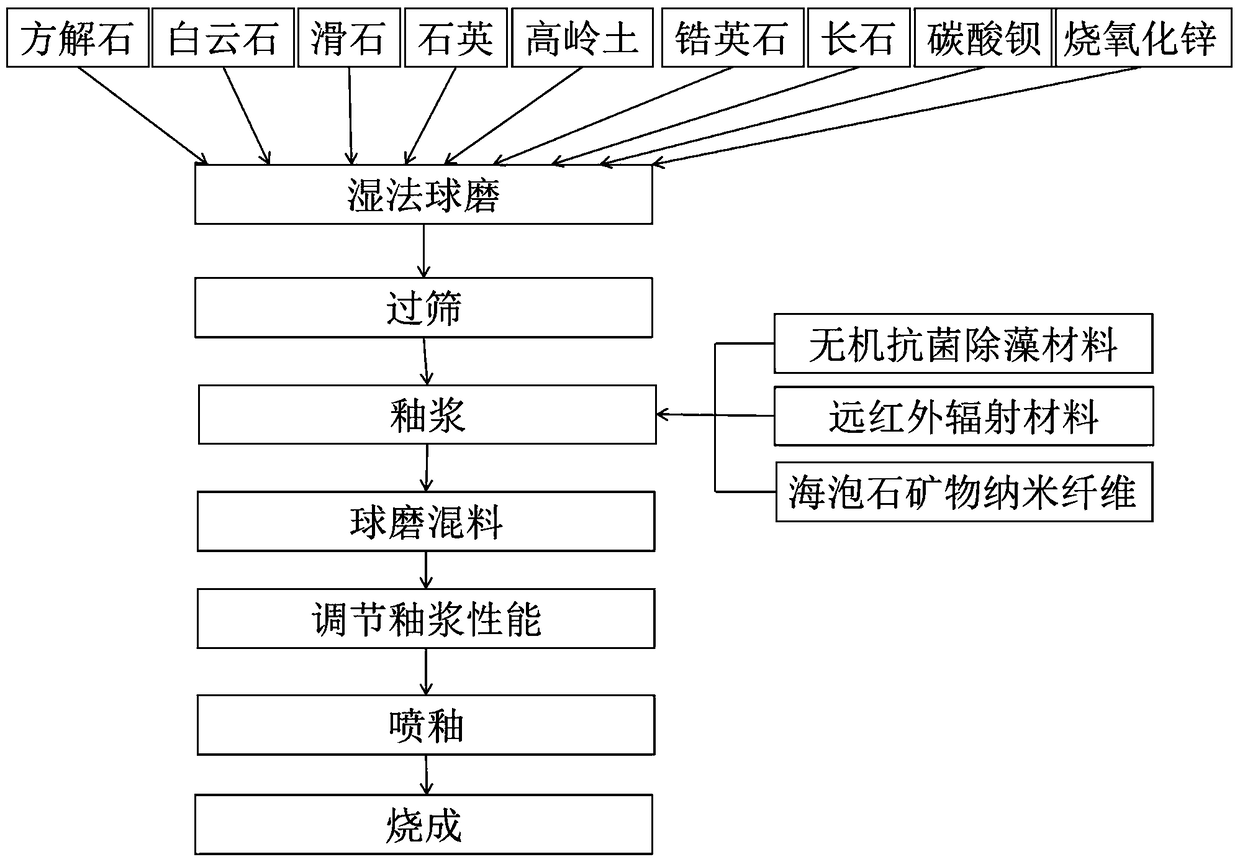

[0040] The production process of the antiscaling functional sanitary ceramics of the present invention comprises the following steps:

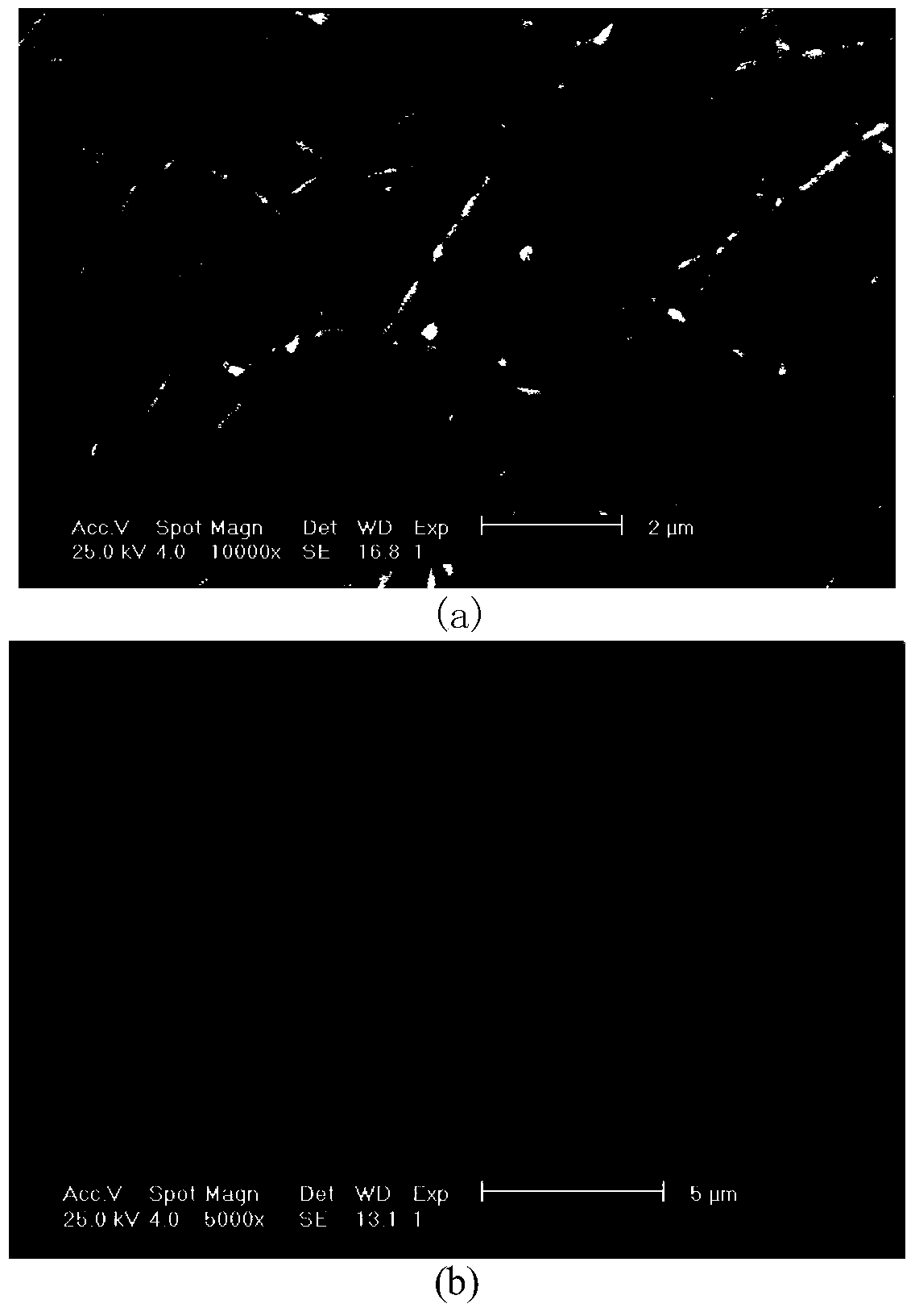

[0041]Glaze preparation: mix calcite, dolomite, talc, feldspar, quartz, kaolin, zircon, barium carbonate, and burnt zinc oxide according to the ratio, and add carboxymethyl cellulose (CMC) with a mass ratio of 0.3% of the above glaze , add water so that water accounts for 35% of the total mass, use zirconia balls as the grinding body, add balls for wet grinding according to the ratio of material: ball = 1:1.5, the glaze particle size D50 is 5 μm, pass through a 120 mesh sieve, and remove iron to obtain For th...

Embodiment 2

[0048] Sanitary ceramics with anti-scale function include the following components (% by weight): 8 calcite, 6 dolomite, 2 talc, 30 feldspar, 25 quartz, 2.5 kaolin, 12 zircon, 0.5 barium carbonate, 1 burnt zinc oxide, 7wt% copper-loaded medical stone 3, 2wt% lanthanum oxide doped medical stone 8, sepiolite mineral nanofiber 2.

[0049] The production process of the antiscaling functional sanitary ceramics of the present invention comprises the following steps:

[0050] Glaze preparation: mix calcite, dolomite, talc, feldspar, quartz, kaolin, zircon, barium carbonate, and burnt zinc oxide according to the ratio, add CMC with a mass ratio of 0.3% of the above glaze, and add water to make the water account for the water. 40% of the total mass of the material, use zirconia balls as the grinding body, add grinding balls according to the ratio of material: ball = 1:1.5, and carry out wet grinding. When the glaze particle size D50 is 5 μm, pass through a 120 mesh sieve to remove iron...

Embodiment 3

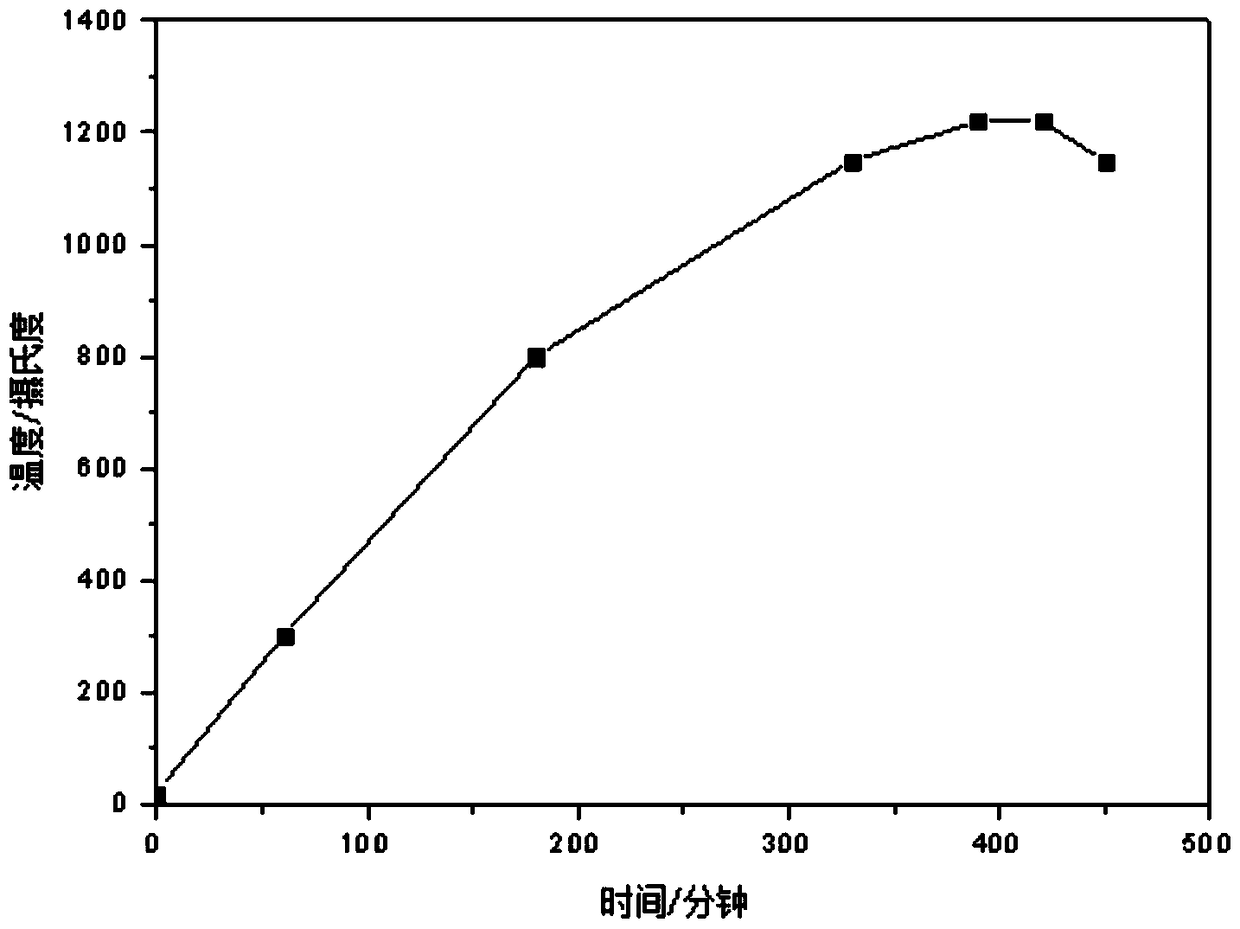

[0055] Other steps are the same as in Example 1, except that calcite, dolomite, talc, feldspar, quartz, kaolin, zircon, barium carbonate, burnt zinc oxide, copper-loaded medical stone, 3wt% cerium oxide doped tourmaline The components are respectively changed to calcite 9, dolomite 5, talc 3, feldspar 31, quartz 24, kaolin 2, zircon 12, barium carbonate 1, burnt zinc oxide 1, 7wt% copper-loaded medical stone 4, 2wt% Neodymium oxide doped with 70wt% tourmaline 28wt% medical stone6, sepiolite mineral nanofiber2. The highest firing temperature is 1200°C. Its properties are: the growth rate of glazed calcite crystals is reduced by 65%, the algae inhibition rate is 97%, the antibacterial rate is 98%, and the Vickers hardness is 660Hv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com