Far-infrared heating slurry, heating coating and preparation method and application of far-infrared heating slurry and heating coating

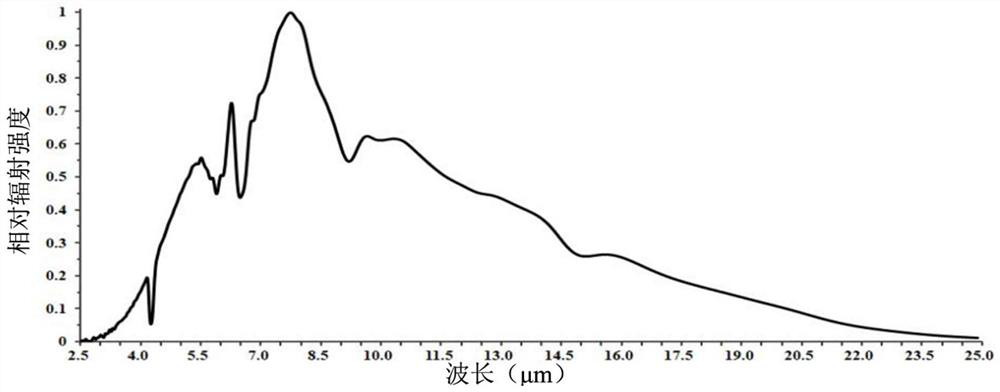

A technology of far-infrared heating and heating coatings, applied in coatings, epoxy resin coatings, etc., can solve the problems of low normal total emissivity, uneven temperature of the radiation surface, low conversion efficiency of electric-thermal radiation, etc., to achieve High normal total emissivity, uniform temperature, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

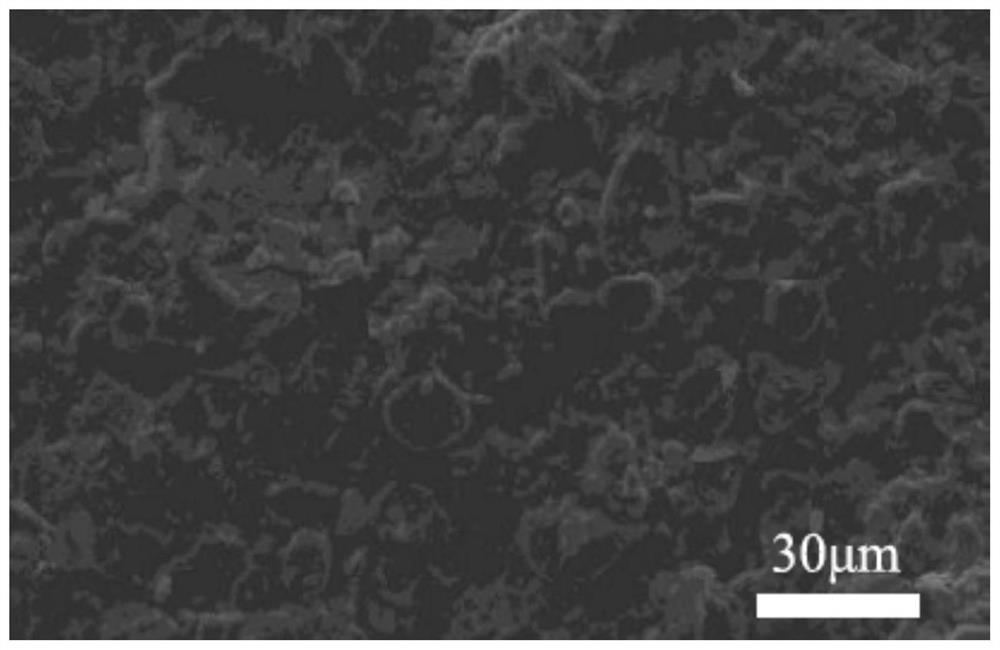

Embodiment 1

[0058] This embodiment provides a far-infrared heating slurry, including 20 parts by weight of graphene, 10 parts of titanium carbonitride (TiCN), 6 parts of molybdenum carbide (Mo 2 C), 15 parts of polyacrylic acid resin (acrylic resin MB-2952, purchased from Shanghai Jiushi Chemical Co., Ltd.), 10 parts of polycarboxylate ammonium salt dispersant (model HT-5020, purchased from Nantong Hantai Chemical Co., Ltd.) , 1 part of wetting agent GS-2455, 0.8 part of defoamer GS-5901, 0.6 part of leveling agent GS-1432, 15 parts of solvent water and 15 parts of solvent ethanol.

[0059] The present embodiment provides a preparation method of far-infrared heating slurry, comprising the following steps:

[0060] In Reactor A, first add 15 parts of solvent water, 5 parts of solvent ethanol, 10 parts of polycarboxylate ammonium salt dispersant, stir at 500r / min for 15min to ensure uniform stirring and mixing, then add 20 parts of graphene, at 700r Continue stirring for 25 minutes at / min...

Embodiment 2

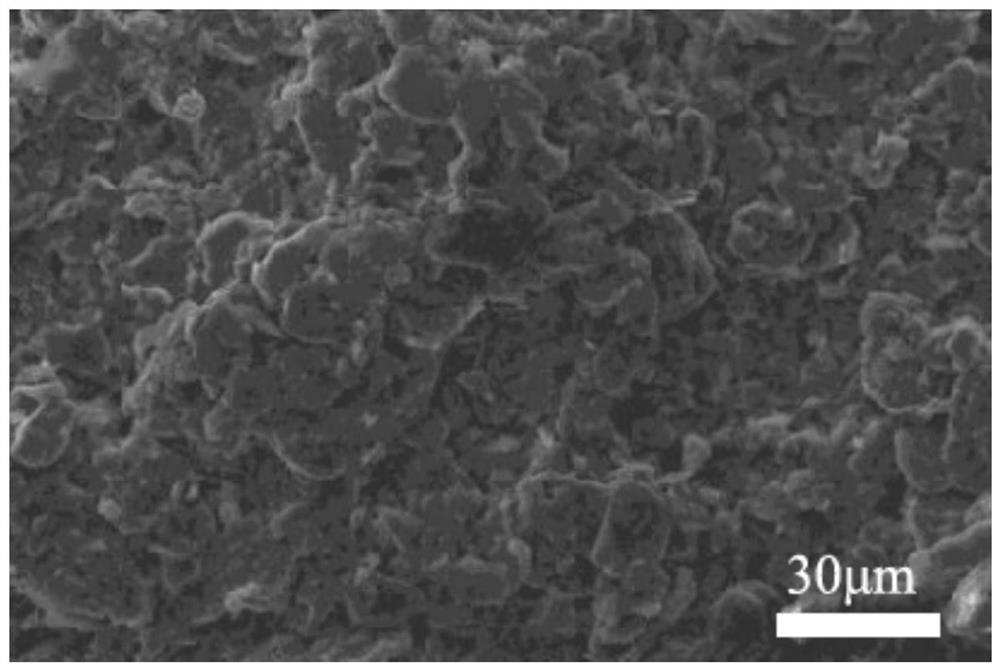

[0067] This embodiment provides a far-infrared heating slurry, including 20 parts by weight of graphene, 10 parts of chromium carbide (Cr 3 C 2 ), 10 parts of tungsten carbide (WC), 15 parts of epoxy resin (model: EPICLON EXA-4850, purchased from Shanghai Diaisheng Fine Chemical Co., Ltd.), 10 parts of polycarboxylate ammonium salt dispersant (model: HT-5020, Purchased from Nantong Hantai Chemical Co., Ltd.), 1 part of wetting agent GS-2455, 0.8 part of defoamer GS-5901, 0.6 part of leveling agent GS-1432, 15 parts of solvent water and 15 parts of solvent ethanol.

[0068] The present embodiment provides a preparation method of far-infrared heating slurry, comprising the following steps:

[0069] In Reactor A, first add 15 parts of solvent water, 5 parts of solvent ethanol, 10 parts of polycarboxylate ammonium salt dispersant, stir at 500r / min for 15min to ensure that the stirring and mixing are uniform, then add 20 parts of graphene, at 700r Continue stirring for 25 minutes...

Embodiment 3

[0076] This embodiment provides a far-infrared heating slurry, which in parts by weight includes 20 parts of graphene, 10 parts of zirconium carbide (ZrC), 10 parts of titanium carbide (TiC), and 15 parts of polyacrylic resin (acrylic resin MB- 2952, purchased from Shanghai Jiushi Chemical Co., Ltd.), 10 parts of polycarboxylate ammonium salt dispersant (model HT-5020, purchased from Nantong Hantai Chemical Co., Ltd.), 1 part of wetting agent GS-2455, 0.8 part of dispersant Foaming agent GS-5901, 0.6 parts leveling agent GS-1432, 15 parts solvent water and 15 parts solvent ethanol.

[0077] The present embodiment provides a preparation method of far-infrared heating slurry, comprising the following steps:

[0078] In Reactor A, first add 15 parts of solvent water, 5 parts of solvent ethanol, 10 parts of polycarboxylate ammonium salt dispersant, stir at 500r / min for 15min to ensure that the stirring and mixing are uniform, then add 20 parts of graphene, at 700r Continue stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com