Non-phosphorus slow-dissolving glass water treatment agent

A technology of water treatment agent and glass water, which is applied in the direction of complex/solubilizer treatment, etc., can solve problems such as limited outlets, environmental protection, etc., and achieve enhanced corrosion inhibition performance, slow down corrosion, excellent anti-corrosion and anti-scaling effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

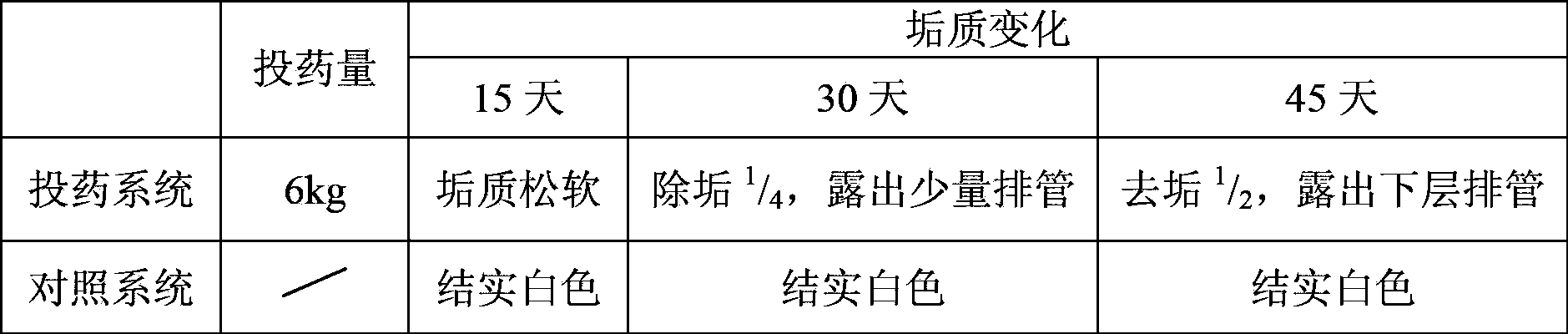

Image

Examples

Embodiment 1

[0029] Weigh glass matrix raw material: sodium oxide Na 2 O 14.0 kg, silicon oxide SiO 2 35.0 kg, boron oxide B 2 o 3 48.0 kg, potassium oxide K 2 O 1.2 kg, alumina Al 2 o 3 1.8 kg;

[0030] Weigh additive raw materials: zinc sulfate ZnSO 4 12.2 kg, sodium tungstate Na 2 WO 4 9.4 kg, silver nitrate AgNO 3 0.18 kg.

[0031] The above-mentioned glass matrix raw materials and additive raw materials are fully stirred, mixed evenly, smelted at 1500°C for 2.5 hours, then quenched, solidified, broken, broken, dried, and sieved to obtain a phosphorus-free slow-dissolving glass water treatment agent. Used in subsequent Test Examples 1-2.

Embodiment 2

[0033] Weigh glass matrix raw material: sodium oxide Na2 O 17.5 kg, silicon oxide SiO 2 30.0 kg, boron oxide B 2 o 3 50.0 kg, potassium oxide K 2 O 1.0 kg, alumina Al 2 o 3 1.5 kg;

[0034] Weigh additive raw materials: zinc sulfate ZnSO 4 10.0 kg, sodium tungstate Na 2 WO 4 7.5 kg, silver nitrate AgNO 3 0.16 kg.

[0035] The above-mentioned glass matrix raw materials and additive raw materials are fully stirred, mixed evenly, melted at 1400°C for 2 hours, then quenched, solidified, broken, broken, dried, and sieved to obtain a phosphorus-free slow-dissolving glass water treatment agent. Used in subsequent Test Examples 1-2.

Embodiment 3

[0037] Weigh glass matrix raw material: sodium oxide Na 2 O 10.0 kg, silicon oxide SiO 2 38.0 kg, boron oxide B 2 o 3 48.8 kg, potassium oxide K 2 O 1.2 kg, alumina Al 2 o 3 2.0 kg;

[0038] Weigh additive raw materials: zinc sulfate ZnSO 4 11.0 kg, sodium tungstate Na 2 WO 4 8.0 kg, silver nitrate AgNO 3 0.17 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com