Energy-saving and environment-friendly building ornament material and preparation method thereof

A technology for building decoration materials, energy saving and environmental protection, applied in the field of building materials, can solve problems such as improper disposal of waste, environmental and ecological pollution, and limitation of application scope, and achieve low cost, stable performance, and simple and easy production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

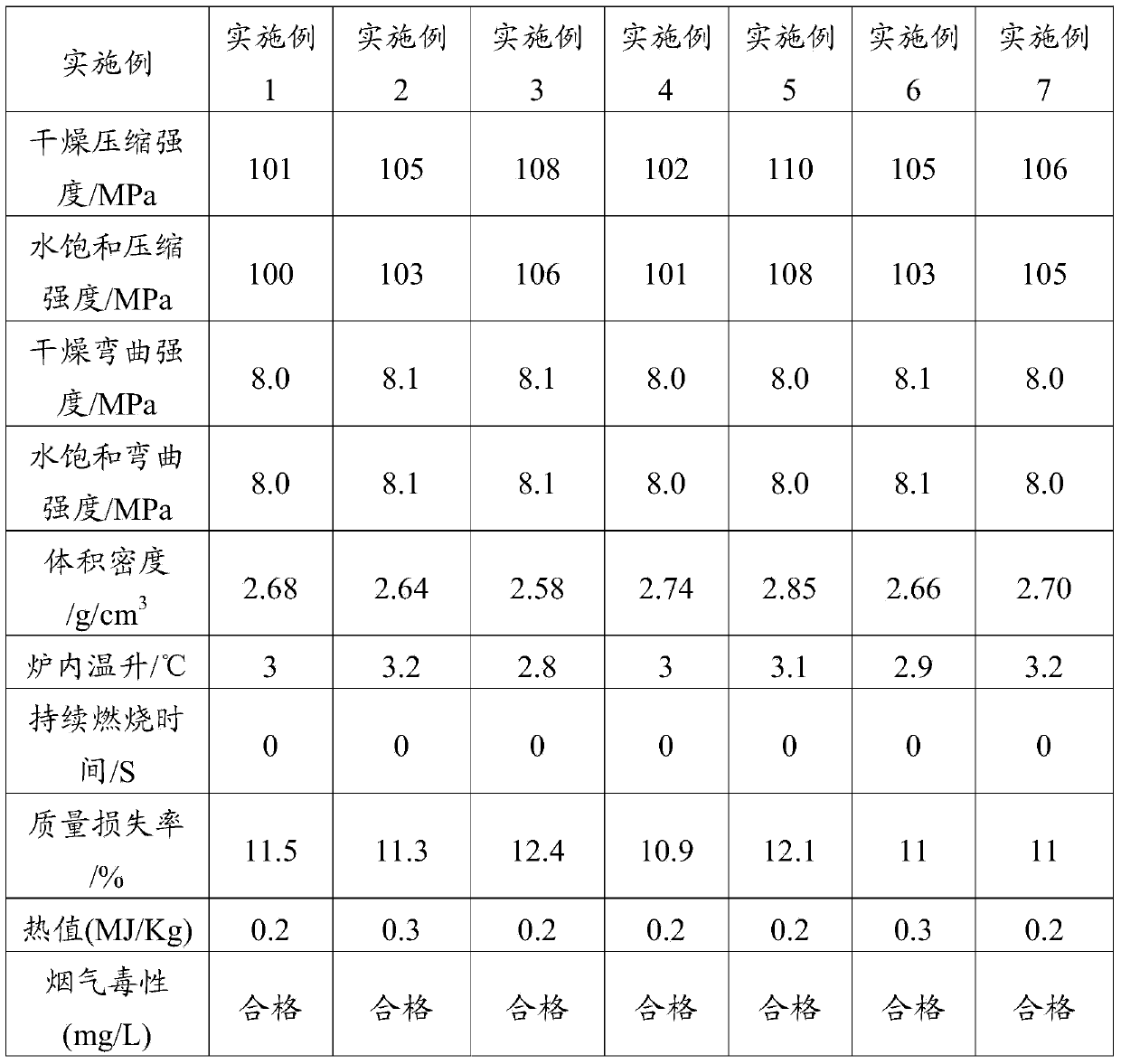

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of an energy-saving and environment-friendly building decoration material, comprising:

[0044]50-70 parts by mass of waste rock slag powder, 10-30 parts by mass of aggregate and / or 3-10 parts by mass of lightweight filler, 10-20 parts by mass of inorganic binder, 1-5 parts by mass of additives, 0-5 parts by mass of inorganic pigments are mixed and stirred evenly, then water of 5wt% to 20wt% of the total weight of the mixture is added, and stirred to obtain a slurry; then the obtained slurry is made into blanks and solidified to obtain architectural decoration Material.

[0045] First of all, the ingredients must be prepared. The raw materials include:

[0046] Waste rock slag powder. The present invention has no special requirements on the material, variety, specification and source of the waste rock slag powder. It can be the waste rock slag powder and leftovers left after general stone processing. Preferably, ...

Embodiment 1

[0059] Mix 60 parts by mass of waste rock powder, 17 parts by mass of aggregate, 20 parts by mass of inorganic binder, 3 parts by mass of auxiliary agent, and 2 parts by mass of inorganic pigment, and stir them evenly to obtain a mixed material, wherein the The waste rock powder is granite waste rock powder with a particle size of 20 to 100 mesh; the aggregate is waste rock slag of 0.1 to 10 mm in natural gradation; the binder is silicon with a weight ratio of 10:25:5:60 A mixture of sodium phosphate, silicon dioxide, aluminum oxide and calcium oxide; the additive is a mixture of modified silicon dioxide and silicon phosphate in a weight ratio of 2:1; after obtaining the mixed material, add 10wt of the total weight of the mixed material % water, stirred to obtain the slurry; the prepared slurry was transported to the mold, and mechanically molded to obtain the green body; after the obtained green body was kept at room temperature (25°C) for 7 days and cured, the finished paveme...

Embodiment 2

[0063] 50 parts by mass of waste rock powder, 27 parts by mass of aggregate, 20 parts by mass of inorganic binder, 3 parts by mass of additives, and 2 parts by mass of inorganic pigment are mixed and stirred evenly to obtain a mixed material, wherein the The waste rock powder is granite waste rock powder with a particle size of 20 to 100 mesh; the aggregate is sand of 0.1 to 1.0 mm in natural gradation; the binder is silicic acid with a weight ratio of 10:15:5:70 A mixture of potassium, aluminum silicate, aluminum oxide and calcium silicate; the additive is a mixture of aluminum phosphate and silicon phosphate in a weight ratio of 1:1; after obtaining the mixed material, add 10wt% water of the total weight of the mixed material , stir to obtain slurry; transfer the prepared slurry to a mold, and perform mechanical molding to obtain a green body; place the obtained green body at room temperature (25°C) for 2 days, and then dry it at 200°C for 4 hours Cool down naturally to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com