A kind of preparation method of liquid tetraketoxime base silane at room temperature

A technology of tetraketoxime and base silane, which is applied in the field of silane crosslinking agent synthesis, can solve the problems of restricted use, use restriction and the like, and achieves the effect of solving the inconvenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

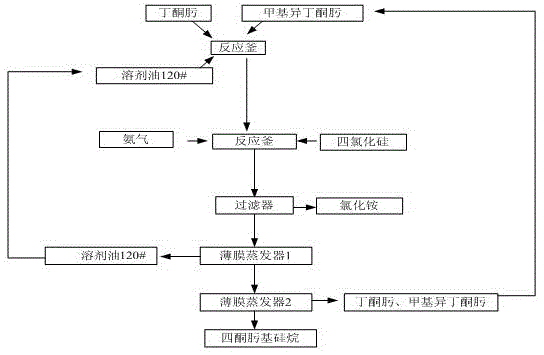

[0022] A kind of preparation method of liquid tetraketoxime base silane at room temperature, its technological process is as follows figure 1 Shown:

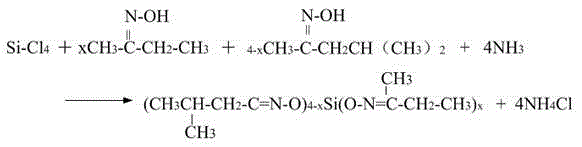

[0023] (1) Raw material ratio: The raw materials are silicon tetrachloride, butanone oxime, methyl isobutyl ketone oxime, ammonia gas and No. 120 solvent oil; according to the molar ratio, silicon tetrachloride: butanone oxime: methyl isobutyl Ketoxime: ammonia=1: (2-2.2): (2-2.2): (4-5.2), the amount of No. 120 solvent oil is 2-4 times the weight of silicon tetrachloride;

[0024] (2) Reaction conditions: Pump butanone oxime, methyl isobutyl ketone oxime and No. 120 solvent oil into the reactor with stirring according to the ratio, and add silicon tetrachloride and ammonia gas at the same time under stirring to control the four The speed of adding silicon chloride and ammonia gas is to keep the reaction temperature at 20-80°C (preferably 30-60°C). After the addition is complete, stop the reaction, filter, and separate the by-p...

Embodiment 1

[0026] Put 306kg of butanone oxime (commercially available), 401kg of methyl isobutyl ketone oxime (commercially available), and 598kg of No. 120 solvent oil (commercially available) into the reaction kettle, and add tetrachloro Silica, the addition rate is 100kg / hr; ammonia gas is passed at the same time, and the rate of ammonia gas flow is 2470 mol / hr. The temperature of the reaction process was controlled at 30°C. When the input amount of silicon tetrachloride was 299kg, stop adding silicon tetrachloride and stop flowing ammonia gas. Filter, separate out ammonium chloride, distill the liquid, first enter the first thin film evaporator, distill out No. 120 solvent oil, then enter the second thin film evaporator, distill out excess butanone oxime and methyl isobutyl Ketoxime, to obtain the product. The first thin-film evaporator controls the temperature at 90°C, and the second thin-film evaporator controls the temperature at 110°C. Obtain product chromaticity 10 (platinum-...

Embodiment 2

[0028] With the butanone oxime of 320kg, the methyl isobutyl ketone oxime of 420kg, No. 120 solvent oils of 598kg, drop in the reactor, under the situation of stirring, add silicon tetrachloride, adding speed is 100kg / hr; Ammonia gas, the rate of passing ammonia gas is 2560 mol / hr. The temperature of the reaction process was controlled at 60°C. When the input amount of silicon tetrachloride was 299kg, stop adding silicon tetrachloride and stop flowing ammonia gas. Filter to separate ammonium chloride. The liquid is distilled, first enters the first thin film evaporator, distills No. 120 solvent oil, then enters the second thin film evaporator, distills excess butanone oxime and methyl isobutyl ketone oxime, and obtains the product. The first thin-film evaporator controls the temperature at 80°C, and the second thin-film evaporator controls the temperature at 100°C. Obtain product chromaticity 10 (platinum-cobalt colorimetric method), obtain product 738kg, product yield 98.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com