Organic-inorganic composite coating on metal surface and preparation process thereof

A preparation process and metal surface technology, applied in coatings, electrolytic coatings, etc., can solve problems such as the unsustainable protective effect of metal substrates, the limitation of coating thickness, uniformity, and the inability of lasting protection of metal substrates, and achieve stable protection effects, The preparation process is simple and easy to implement, and the effect of low flatness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

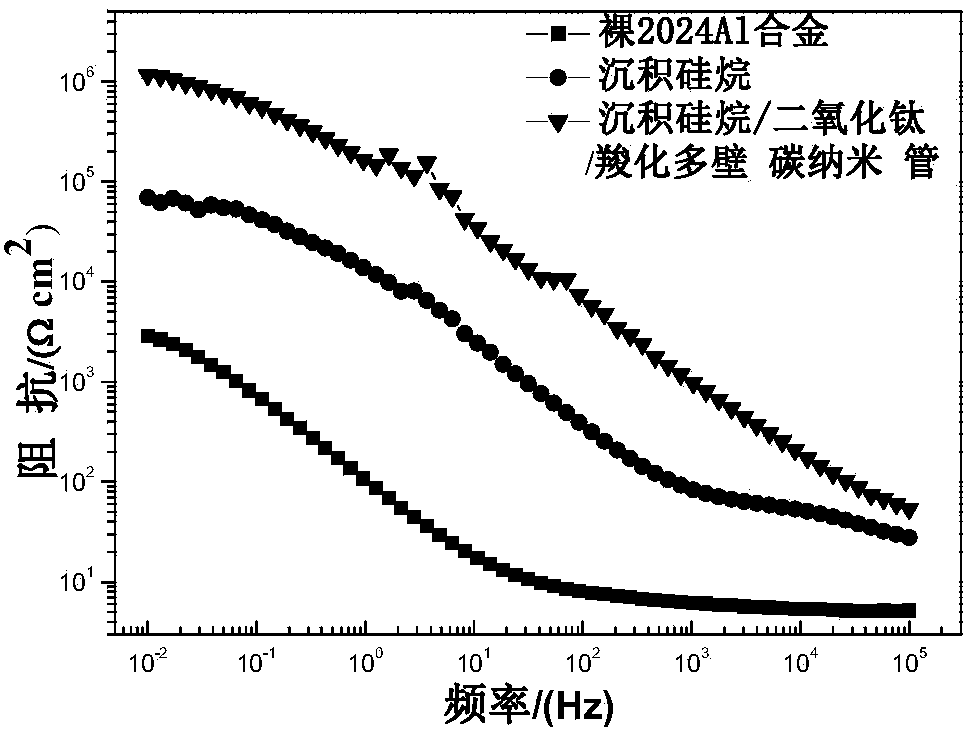

[0023] Example 1 : The sol of carboxylated carbon nanotubes covered by inorganic nanoparticles was added to the silane coupling agent on the surface of 2024Al alloy to prepare organic-inorganic composite coatings.

[0024] (1) Prepare 2%wt bis-[3-(triethoxy)silylpropyl]tetrasulfide (BTESPT) silane solution. BTESPT: deionized water: absolute ethanol, the volume ratio is 2:3:95, after ultrasonic dispersion for 20min, adjust the pH to 4.5 with glacial acetic acid, and keep in a constant temperature water bath at 25°C for 48h.

[0025] (2) Preparation of carboxylated multi-walled carbon nanotubes. Measure 0.15g of multi-walled carbon nanotubes, 10mL of concentrated nitric acid, and 30mL of concentrated sulfuric acid, put them into a three-neck flask for heating and stirring, mix and ultrasonically disperse in a water bath for 30 minutes, and then reflux in a water bath at 60°C for 4 hours. Pour the reacted product into a beaker for rapid cooling: put the beaker in an ice bath t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com