A kind of organic-inorganic hybrid polymer solid electrolyte material and its application

A technology of solid electrolyte and solid electrolyte membrane, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as poor safety performance and poor cycle stability, and achieve enhanced mechanical properties, stable cycle performance, and increased migration rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare a polymer electrolyte whose components are MIL-53(Al), polyethylene oxide (PEO), and lithium bistrifluoromethanesulfonimide (LiTFSI). The specific preparation process is as follows:

[0034] Synthesis of MOF: According to the technical requirements, first synthesize MIL-53 (Al), according to the molar ratio of aluminum nitrate nonahydrate (Al (NO 3 ) 3 9H 2 O): Terephthalic acid (H 2 BDC): N-N dimethylformamide (DMF): deionized water (H 2 O)=1:0.5:153:80, add 1.5g (4mmol) Al(NO 3 ) 3 9H 2 O, 0.664 g (2 mmol) H 2 BDC, 15mLDMF and 5.76mLH 2 O, react in an autoclave for 48 hours at 150°C and a stirring speed of 400r / min to obtain a white milky substance, which is washed with deionized water at a volume ratio of 1:1, filtered, and vacuum-dried at 130°C After 24 hours, a white powder of MIL-53(Al) nanoparticles was obtained, and the particle size range was distributed between 5 nm and 20 μm.

[0035] Film formation: Dissolve 0.1g of the prepared white powder...

Embodiment 2

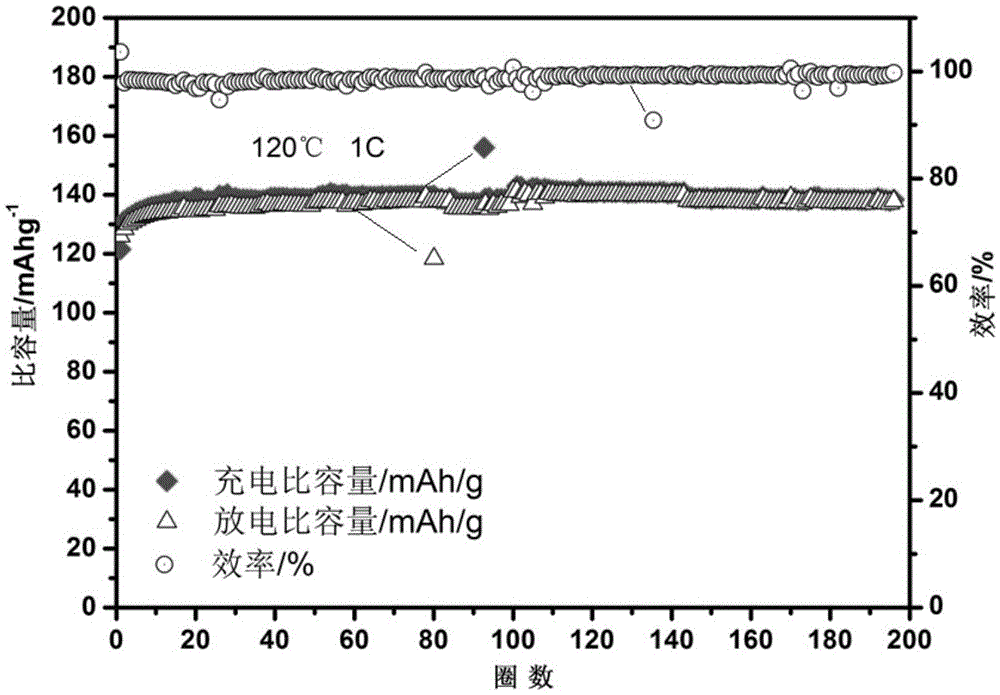

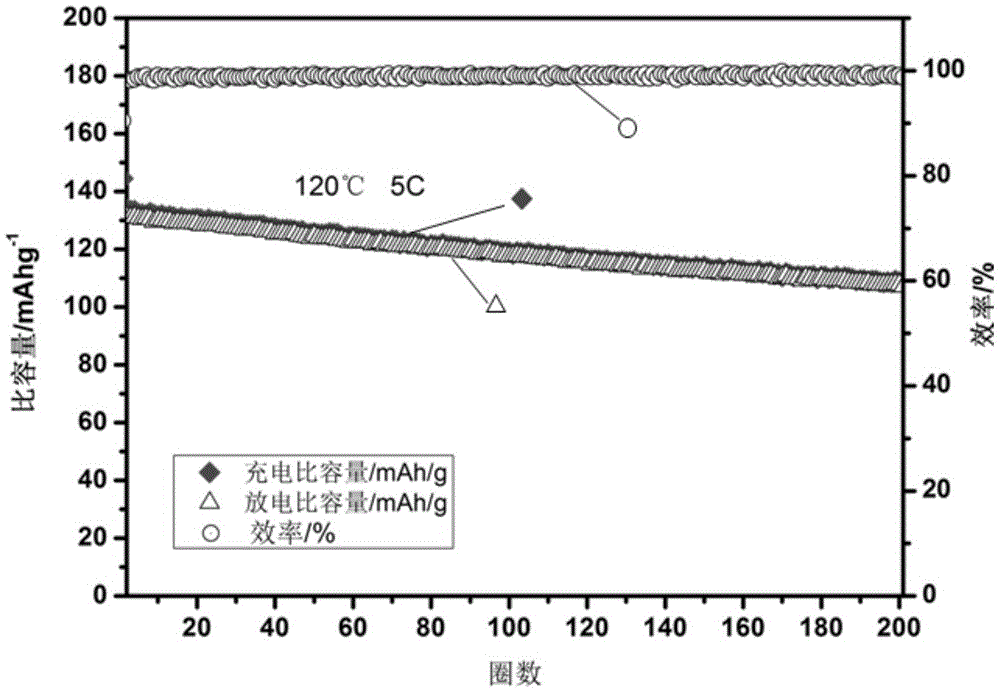

[0038] Prepare the same polymer electrolyte as in Example 1 and assemble into LiFePO 4 Half-battery, 1C rate charge and discharge test at 120°C, the first charge specific capacity is 131.1mAh / g, the discharge specific capacity is 128.4mAh / g, the efficiency is 97.9%, and the charge specific capacity after 200 cycles is 138.3mAh / g g, the discharge specific capacity is 137.8mAh / g, and the efficiency is 99.7%. The 5C rate charge and discharge test was carried out at 120°C. The first charge specific capacity was 133.8mAh / g, the discharge specific capacity was 131.2mAh / g, and the efficiency was 98.1%. After 200 cycles, the charge specific capacity is 108.7mAh / g, the discharge specific capacity is 107.8mAh / g, and the efficiency is 99.1%. Specific cycle test data such as figure 1 (a) (b) shown.

Embodiment 3

[0040] The preparation component is MIL-53 (Cr), LiBOB, the polymer electrolyte membrane of polyvinylidene fluoride, and its preparation method is as follows:

[0041] Synthesis: The first is the preparation of MIL-53(Cr), according to the molar ratio of 1:2, weigh 1.6g (4mmol) of Cr(NO 3 ) 3 9H 2 O, and 0.332g (2mmol) terephthalic acid (H 2 BDC) into the flask, add 5mL of deionized water and 1mL of hydrofluoric acid (HF), stir for 60min at a speed of 400r / min, react in a polytetrafluoroethylene autoclave at 220°C for 72h, cool, and use 50 mL of deionized water was left to wash for 12 hours, filtered, and vacuum-dried at 120° C. for 12 hours to obtain white nanoparticles MIL-53 (Cr), with particle sizes ranging from 5 nm to 20 μm.

[0042] Membrane production: Weigh 0.15 g of white nanoparticles MIL-53 (Cr) and 0.2 g of LiBOB, dissolve in 15 mL of acetonitrile, stir for 2 h, add 0.4 g of PVDF to the above solution, stir for 48 h, and rotate at 700 r / min. First, the solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com