Stainless-steel sheet for metal mask

A technology of stainless steel plate and metal mask, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve problems such as corner cracks, achieve the effect of improving strength, increasing productivity, and suppressing thermal influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Hereinafter, an example and a comparative example of the present invention will be described.

[0059] [Production of stainless steel plate]

[0060] Stainless steels having the respective compositions shown in Table 1 were melted in a 30 kg vacuum furnace and cast into ingots. The obtained ingot was divided into slabs, and the slabs were hot-rolled at 920° C. to form hot-rolled steel strips with a thickness of 3.0 mm.

[0061] [Table 1]

[0062] Steel No.

C

Si

mn

P

S

Ni

Cr

N

Mo

Cu

A1

V

B

Ti

Nb

Remark

1

0.070

0.50

0.30

0.025

0.001

2.0

16.3

0.01

—

—

—

—

—

—

—

—

2

0.085

0.70

1.40

0.030

0.001

1.2

15.0

0.01

—

—

—

—

—

—

—

—

3

0.065

0.50

0.25

0.003

0.001

2.1

15.2

0.01

—

—

—

0.60

—

—

—

V

...

PUM

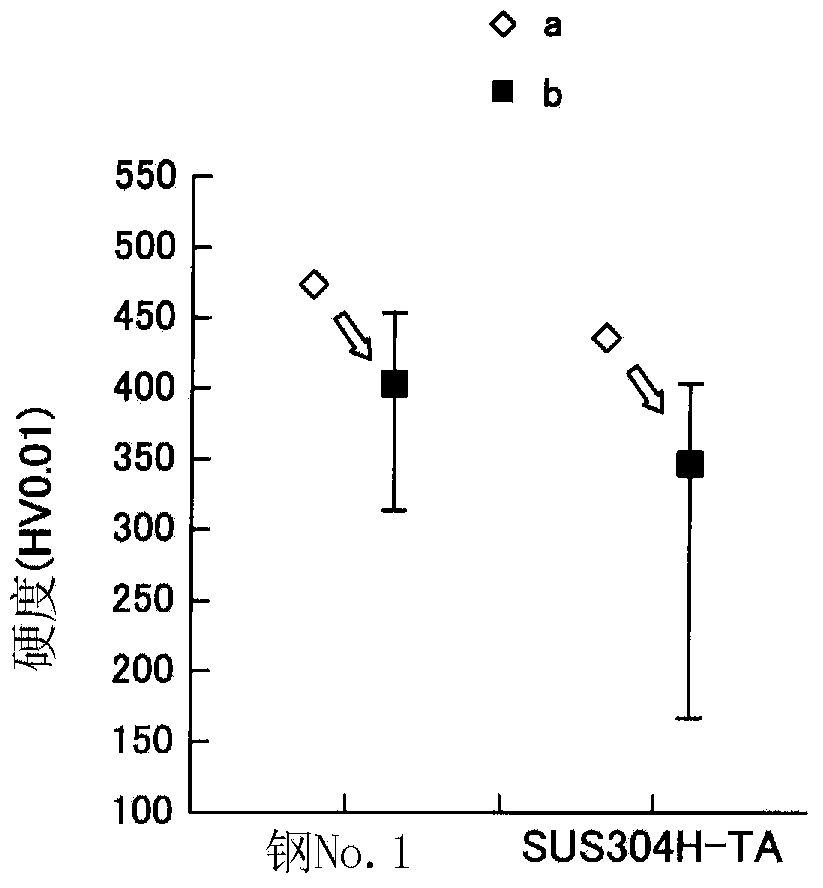

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com