Processing method for program control weak electrolyte dipping function food based on magnetic trap

A technology of weak electrolyte and processing method, applied in the direction of food forming, food science, application, etc., can solve the problems of over salty products and difficult quality control, and achieve the effect of strengthening functional ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

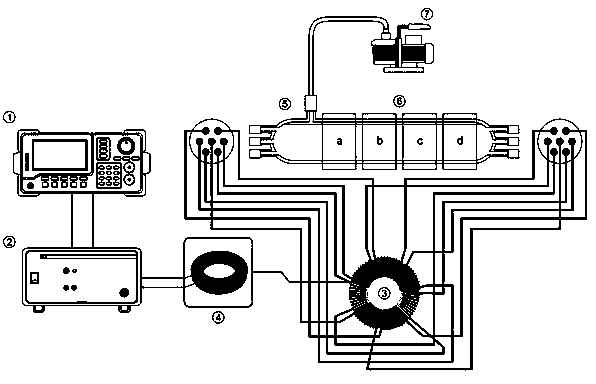

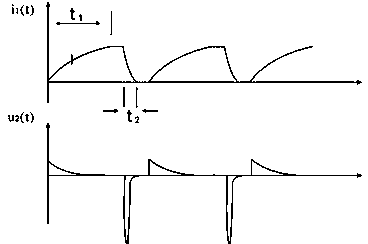

[0022] Example 1: Quick anti-browning dipping of potato slices

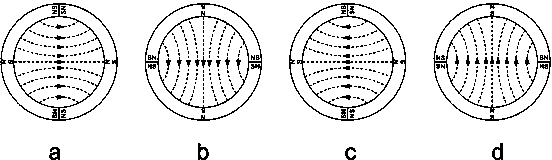

[0023]After peeling the potatoes, cut them into slices with a thickness of 3mm and place them in the dipping tank. The cavity size of the groove is 100mm in inner diameter, 600mm in length, and 3mm in wall thickness. There is a radial magnetic field array composed of 4 pairs of semicircular magnetic tiles located outside the chamber of the dipping tank. The angles of the central magnetic field lines of each adjacent pair of annular magnetic tiles differ by 90 degrees. The size of a semicircular magnetic tile is 120mm inner diameter, 135mm outer diameter, 15mm thick, and 100mm long. The magnetic field on the center surface of the magnetic tile is 3000Gs, and the center strength of the radial magnetic field composed of each pair of magnetic tiles is 400Gs. Inject the impregnating solution, whose ascorbic acid and citric acid contents are 0.08% and 0.5% respectively, until the sample is submerged. At this time, the...

Embodiment 2

[0024] Embodiment 2: pork skin flavoring

[0025] 2-Methylhexanoic acid is soluble in water and has a greasy smell of lard and chicken fat. This example is for adding flavor to rehydrated fried pork skin. Weigh 300 grams of dried pigskin, soak and rehydrate, cut into 1×1×5cm strips, and place them in a dipping tank. The cavity size of the groove is 100mm in inner diameter, 600mm in length, and 3mm in wall thickness. There is a radial magnetic field array composed of 4 pairs of semicircular magnetic tiles located outside the chamber of the dipping tank. The angles of the central magnetic field lines of each adjacent pair of annular magnetic tiles differ by 90 degrees. The size of a semicircular magnetic tile is 120mm inner diameter, 135mm outer diameter, 15mm thick, and 100mm long. The magnetic field on the center surface of the magnetic tile is 3000Gs, and the center strength of the radial magnetic field composed of each pair of magnetic tiles is 400Gs. Inject 2-methylhexano...

Embodiment 3

[0026] Example 3: Glutamate Fortified Carrots

[0027] L-glutamic acid is often added as a food nutritional supplement to liquid food or food that needs to be crushed and restructured. The food selected in this example is a semi-moist solid. Weigh 800 grams of fresh carrots, peel and wash, cut into 2×2×2cm blocks, and place them in a dipping tank. The cavity size of the groove is 100mm in inner diameter, 600mm in length, and 3mm in wall thickness.

[0028] There is a radial magnetic field array composed of 4 pairs of semicircular magnetic tiles located outside the chamber of the dipping tank. The angles of the central magnetic field lines of each adjacent pair of annular magnetic tiles differ by 90 degrees. The size of a semicircular magnetic tile is 120mm inner diameter, 135mm outer diameter, 15mm thick, and 100mm long. The magnetic field on the center surface of the magnetic tile is 3000Gs, and the center strength of the radial magnetic field composed of each pair of magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com