Preparation method of polyethylene glycol-polyester triblock copolymer drug-loaded nanomicelle

A technology of polyethylene glycol and drug-loaded nanometers, which is applied in the field of polymers, can solve problems such as the limitation of preparation methods of drug-loaded micelles, and achieve the effects of improving encapsulation efficiency and solubility, simple operation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

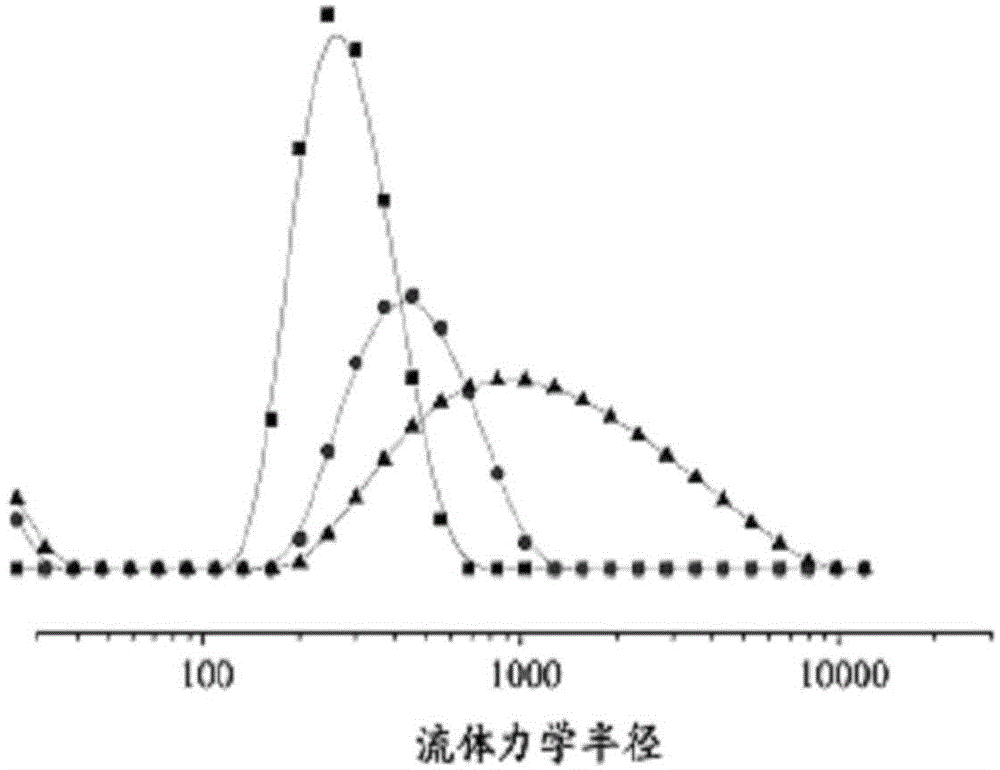

[0032] The embodiment of the present invention discloses a preparation method of a polyethylene glycol-polyester triblock copolymer drug-loaded nanomicelle, comprising the following steps:

[0033] (A) drop the mixture of small molecule drug and organic solvent into polyethylene glycol-polyester triblock copolymer to obtain a mixed solution;

[0034] (B) adding ultrapure water dropwise while stirring the mixed solution for the first time, after continuing the second stirring, dialysis to remove the organic solvent and freeze-drying to obtain drug-loaded nanomicelles;

[0035] The polyethylene glycol-polyester triblock copolymer is shown in formula (I),

[0036]

[0037] where -R- is or

[0038] m is the degree of polymerization, 10≤m≤250, preferably 40≤m≤200, more preferably 60≤m≤150; n is the degree of polymerization, 10≤n≤220, preferably 30≤n≤20, more preferably 60≤n≤150.

[0039] In the present invention, the nano-sedimentation method is used to prepare the polyet...

Embodiment 1~6

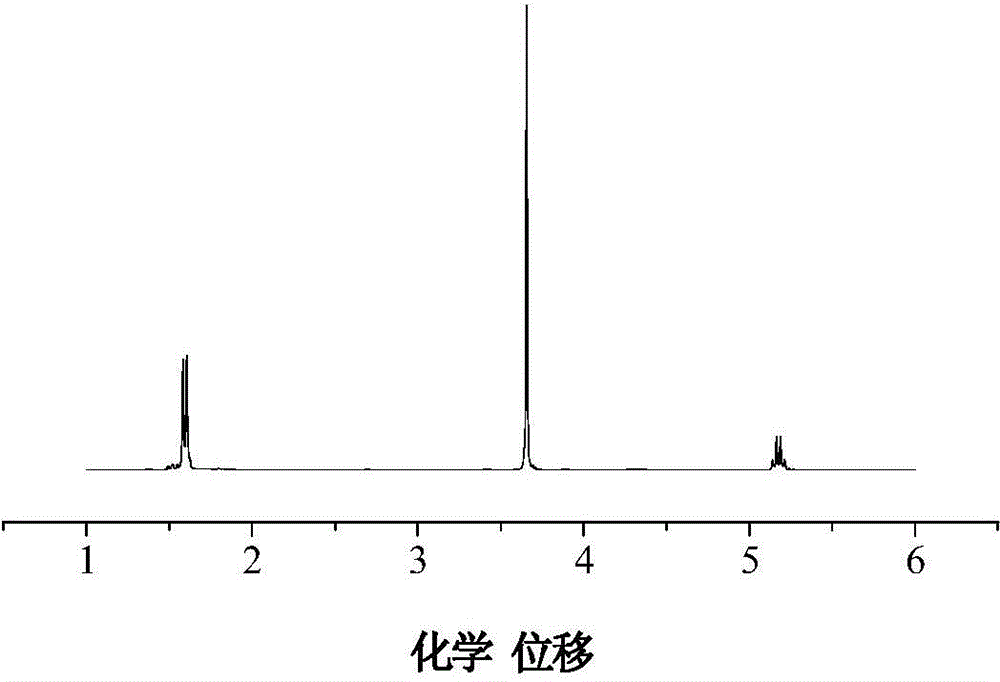

[0052] Preparation of polyethylene glycol-poly(D-lactide) triblock copolymers initiated by polyethylene glycol with different number average molecular weights

[0053] Weigh polyethylene glycol (PEG) 1.67g, 6.67g, 13.33g, 16.67g, 33.33g, 66.57g with molecular weights of 1000, 4000, 8000, 10000, 20000, and 40000, respectively, and put them into the reaction flask, and azeotropically remove them. Water, add 12 g of D-lactide (DLA) in an anhydrous and oxygen-free environment, ventilate, the volume (mL) of toluene is 10 times the weight (g) of the ester monomer, 120 mL, the volume of stannous octoate and The molar ratio of the ester monomer was 1 / 1000, and 1 mL of 0.1 mol / L stannous octoate toluene solution was injected with a syringe, and then put into an oil bath at 120°C for reaction for 24 hours. After the reaction is completed, the solution is cooled, and 1200 mL of diethyl ether is used to settle while stirring. The amount ratio of diethyl ether and toluene is 10 / 1. The Buch...

Embodiment 7~10

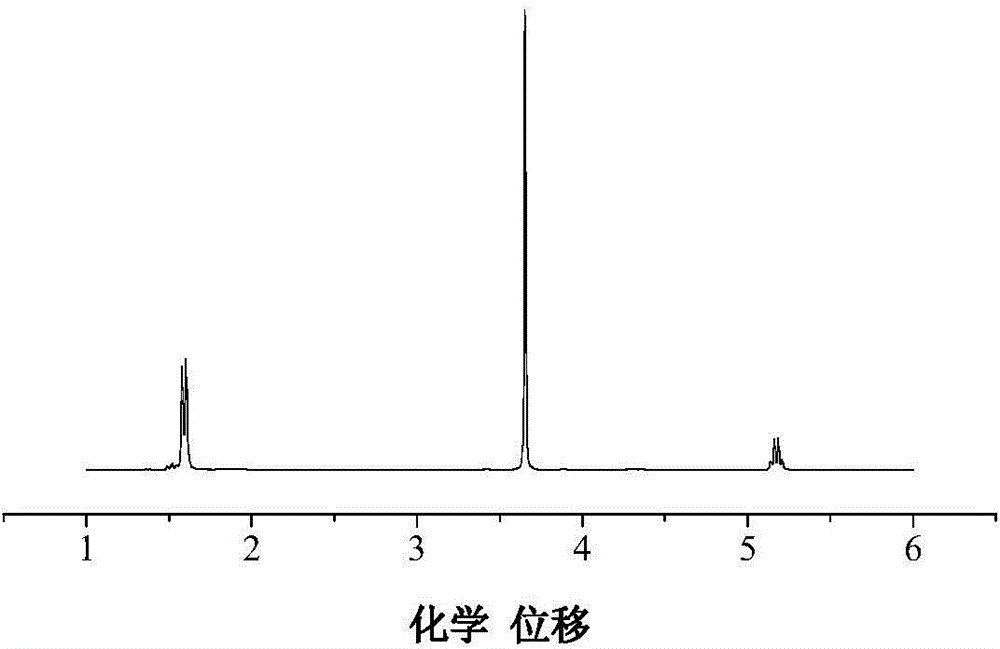

[0059] Preparation of polyethylene glycol-poly(D-lactide) triblock copolymers with different degrees of polymerization initiated by polyethylene glycol

[0060] Weigh 4g, 6g, 8g, 12g of polyethylene glycol (PEG) with a molecular weight of 4000 and put them in a reaction flask, remove water azeotropically, and add 12g of D-lactide (DLA) in an anhydrous and oxygen-free environment. Ventilation, the volume (mL) of toluene is 10 times the weight (g) of the ester monomer, 120mL, the volume of stannous octoate and the molar ratio of the ester monomer are 1 / 1000, and 0.1mol / L octanoic acid is injected with a syringe 1 mL of stannous solution in toluene was put into an oil bath at 120 °C for 24 h. After the reaction is completed, the solution is cooled, and 1200 mL of diethyl ether is used to settle while stirring. The amount ratio of diethyl ether and toluene is 10 / 1. The Buchner funnel is filtered, and the obtained product is dissolved in chloroform, and then settled with diethyl et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com