A casting method for a cylinder head of a marine diesel engine without cooling iron

A marine diesel engine and cylinder head technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of complex and difficult production operations, many factors to consider in casting methods, and high energy consumption, so as to eliminate leakage quality problems, casting cost savings, and the effect of improving surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

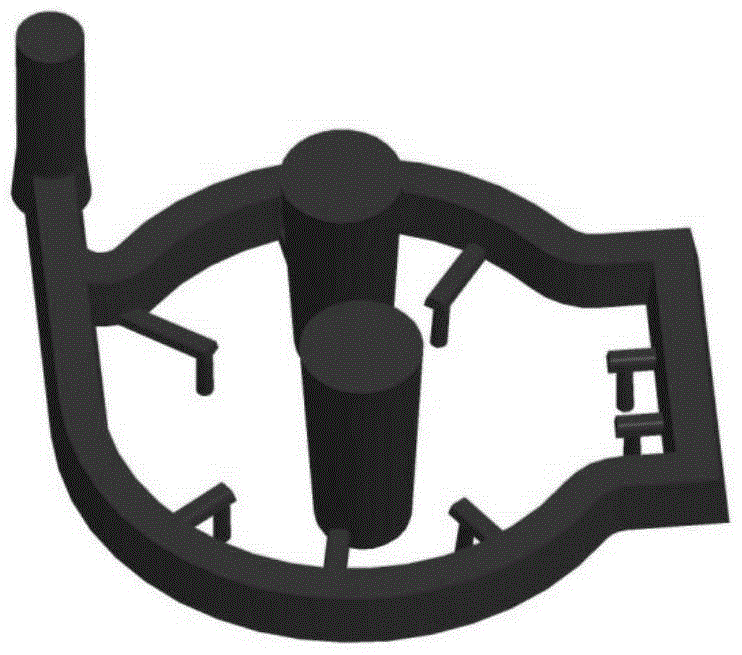

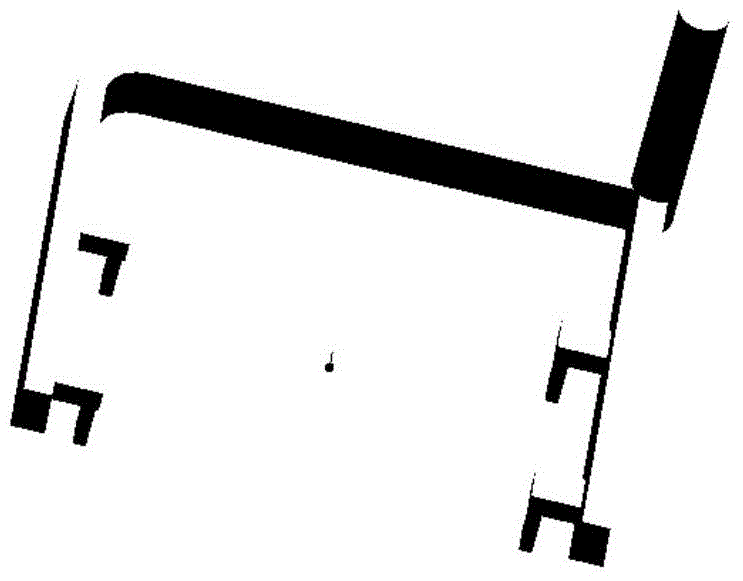

Image

Examples

Embodiment 1

[0047] M-type diesel engine cylinder head is made of HT350 cast iron, two pieces for each type, refractory pipe top injection, and two thermal insulation risers are designed to lead the ventilation of the core to the outside of the cavity. The top pouring system is adopted, and on the top surface of the cylinder head, 8 ingates are distributed from the top, thereby improving the temperature field distribution of the cylinder head casting and reducing the formation of shrinkage cavity and shrinkage defects of the casting. According to the solidification characteristics of the alloy material of the cylinder head, and taking into account the structure of the cylinder head itself. On the thick part of the casting, two Riser, Riser neck The riser not only plays the role of feeding, but also can discharge the gas in the cavity smoothly, and can also play the role of slag collection. Simultaneously set 5 on the top surface Air outlet rod, used to remove cavity gas.

[0048] Va...

Embodiment 2

[0051] The L-type diesel engine cylinder head is made of HT300 iron castings, and the castings are pressed to prevent leakage. The top injection pouring system is adopted, and the temperature drops rapidly during the pouring process. Since the casting can be filled smoothly, the lower the temperature, the smaller the liquid shrinkage, and the less conducive to the formation of shrinkage cavities and shrinkage porosity, so the top injection method is adopted. The gating system will improve the internal distribution of the cylinder head casting and reduce the formation of shrinkage cavity and porosity defects of the casting. At the same time, the temperature of the molten iron at the riser is higher than the internal temperature of the casting, which will also enhance the feeding effect of the casting. On the two thick parts of the top surface of its casting, two dimensions are placed Riser, Riser neck The riser not only plays the role of shrinkage feeding, but also can disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com