Manufacturing method of rotationally-forged aluminum alloy hub

An aluminum alloy wheel hub and aluminum alloy technology, which is applied in the field of automobile parts manufacturing, can solve the problems of high energy consumption and cost, high forging cost, complicated process, etc., and achieve the effects of reducing energy consumption, improving alloy structure and simplifying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

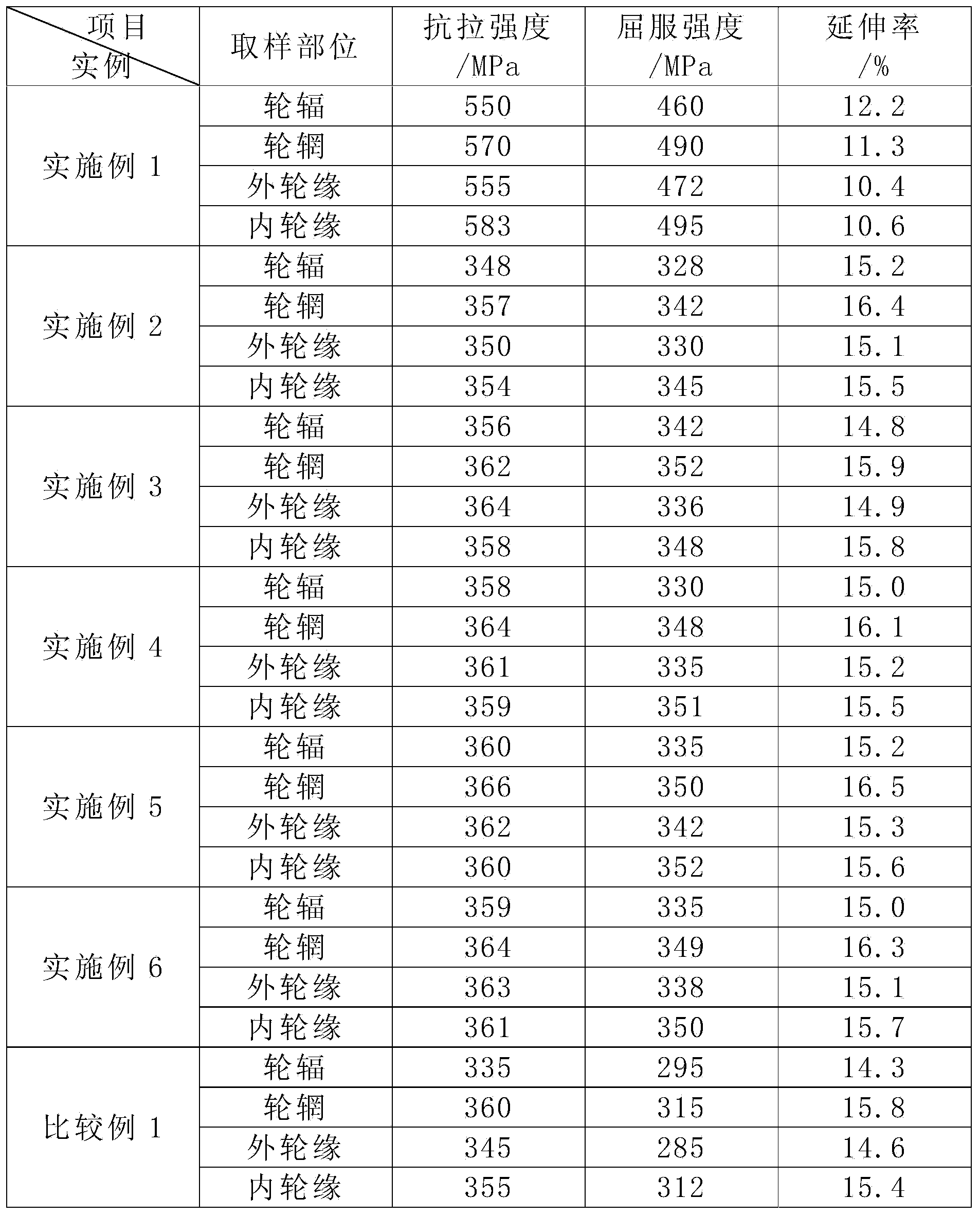

Embodiment 1

[0030] This embodiment is based on a 17-inch automobile forged aluminum alloy wheel hub:

[0031] According to the size of the aluminum alloy wheel hub, the volume of the required blank is calculated, and the aluminum alloy hot-rolled thick plate is punched into a round cake-shaped blank; more specifically, the 7A04 aluminum alloy thick plate with a thickness of 65mm is punched into a size of Φ350mm×65mm round cake-shaped billet; then, the billet surface is cleaned and degreased; preferably, the 7A04 aluminum alloy hot-rolled thick plate is made of 7A04 aluminum alloy ingot through hot rolling;

[0032] Put the round cake-shaped blank obtained by punching above into a heating furnace and heat it to 440°C for preheating for 30 minutes;

[0033] Before forging and pressing, preheat the mold to 450°C in 20 minutes, separate the upper mold and the lower mold of the mold, and spray a lubricant on the working surface of the mold, such as artificial wax; then, the above Put the preh...

Embodiment 2

[0036]This embodiment is based on a 17-inch automobile forged aluminum alloy wheel hub:

[0037] According to the size of the aluminum alloy wheel hub, the volume of the required blank is calculated, and the aluminum alloy hot-rolled thick plate is punched into a round cake-shaped blank; more specifically, the 6061 aluminum alloy hot-rolled thick plate with a thickness of 65mm is punched into a size of Φ350mm×65mm round cake-shaped blank; then, cleaning and degreasing the surface of the blank; preferably, the 6061 aluminum alloy hot-rolled thick plate is made of 6061 aluminum alloy ingot through hot rolling;

[0038] Put the round cake-shaped blank obtained by punching above into a heating furnace and heat to 470°C for preheating for 40 minutes;

[0039] Before forging and forming, preheat the mold to 460°C in 25 minutes, separate the upper mold and the lower mold of the mold, and spray a lubricant on the working surface of the mold, such as artificial wax; then, the above Pu...

Embodiment 3

[0042] This embodiment is based on a 17-inch automobile forged aluminum alloy wheel hub:

[0043] According to the size of the aluminum alloy wheel hub, the volume of the required blank is calculated, and the aluminum alloy hot-rolled thick plate is punched into a round cake-shaped blank; more specifically, the 6061 aluminum alloy hot-rolled thick plate with a thickness of 58mm is punched into a size of Φ370mm×58mm circular cake-shaped blank; then, clean and degrease the surface of the blank;

[0044] Put the round cake-shaped blank obtained by punching above into a heating furnace and heat to 450°C for preheating for 40 minutes;

[0045] Before forging and forming, preheat the mold to 450°C in 20 minutes, then separate the upper mold and the lower mold of the mold, and spray a lubricant on the working surface of the mold, such as artificial wax; then, Put the above-mentioned preheated round cake-shaped blank into a mold, and use a 1500-ton forging press to perform forging an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com