Preparation method of spherical hydroxy cobalt oxide

A cobalt oxyhydroxide, spherical technology, applied in the field of preparation of spherical cobalt oxyhydroxide, can solve the problems of complex process, difficult particle size control, loose secondary particle structure, etc., and achieves the effects of simple process, low cost and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The embodiment of the present invention provides a method for preparing spherical cobalt oxyhydroxide. The method utilizes the controlled crystallization method to react the reactants in a controlled crystallization tank with a buffer while performing non-uniform stirring, specifically comprising the following steps:

[0018] S1, providing a controlled crystallization kettle;

[0019] S2, injecting a buffer into the controlled crystallization tank, the buffer is used to control the reaction speed of the reactants;

[0020] S3, using the cobalt salt solution and the alkaline solution as reactants, injecting the controlled crystallization kettle with a buffer; and

[0021] S4. Stir the reactant only at the bottom area of the tank body of the controlled crystallization tank while reacting the reactant, so as to prepare spherical cobalt oxyhydroxide by a controlled crystallization method.

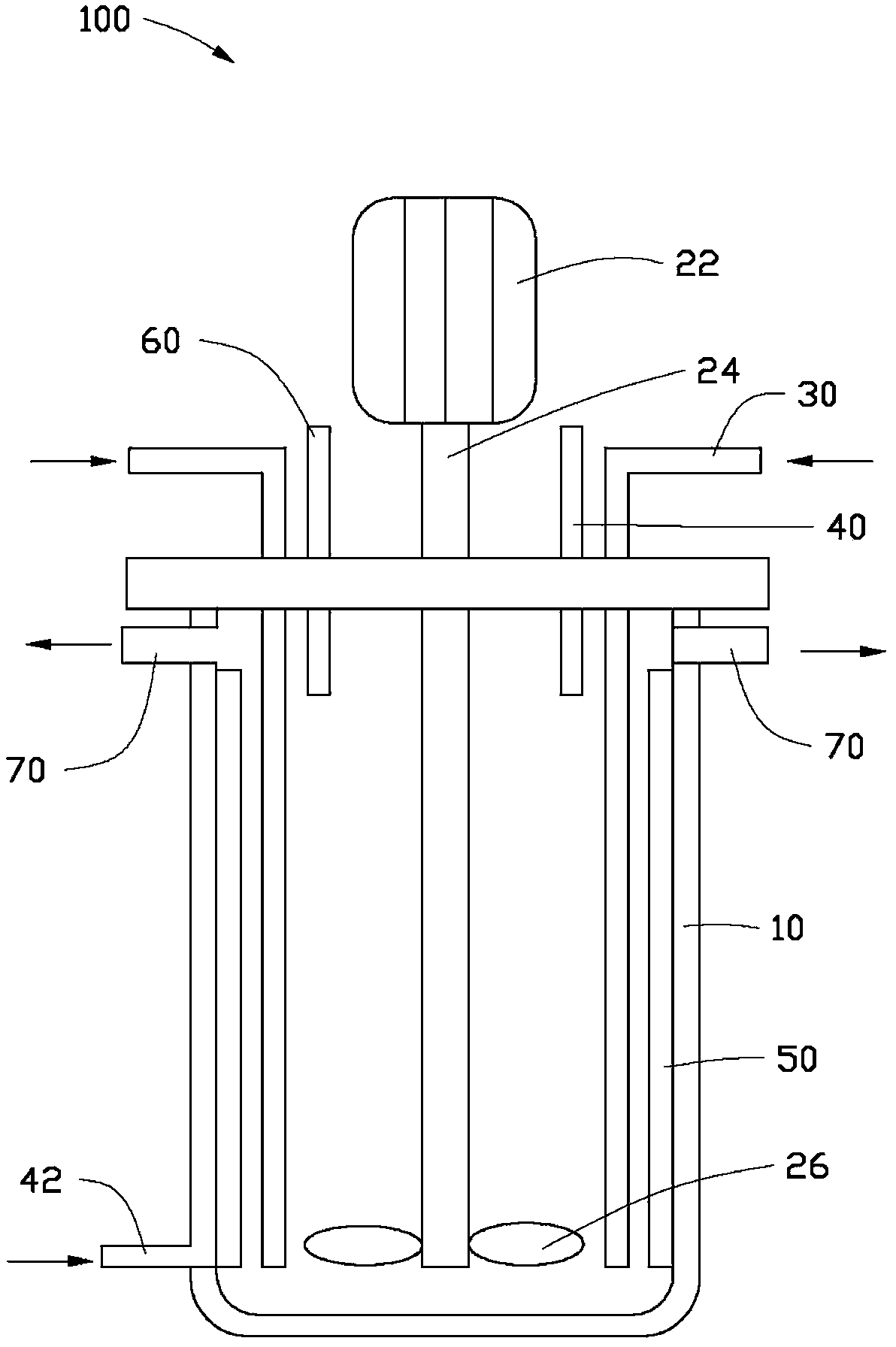

[0022] see figure 1 , The controlled crystallization kettle 100 includes a kettl...

Embodiment 1

[0053] 1) Add 4 mol / L ammonia solution into a 4-liter controlled crystallization kettle as a buffer, mechanically stir vigorously at 1,500 rpm, and slowly add 2 mol / L chloride from both sides with a peristaltic pump Cobalt aqueous solution and 4 mol / L sodium hydroxide aqueous solution, the feed rate is controlled at 0.5 milliliters per minute to obtain spherical cobalt oxyhydroxide.

[0054] 2) Take out the reaction product spherical cobalt oxyhydroxide in 1), repeatedly wash with deionized water and suction filter to preserve the obtained spherical cobalt oxyhydroxide;

[0055] 3) Mix 1 kg of the spherical cobalt oxyhydroxide obtained in 2) with an aqueous solution containing 400 g of saturated lithium hydroxide and put it into a high-pressure hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction kettle should be heated rapidly to 150°C and Insulated for 5 hours to obtain spherical lithium cobaltate;

[0056] 4) Take out the reaction product lithi...

Embodiment 2

[0060] 1) Add 8 mol / L ammonia solution in a 10-liter controlled crystallization kettle as a buffer, mechanically stir vigorously, the stirring intensity is 900 rpm, and slowly add 3 mol / L chloride from both sides with a peristaltic pump Cobalt aqueous solution and 6 mol / L sodium hydroxide aqueous solution, the feeding speed of two kinds of solutions all is controlled at 2 milliliters per minute, obtains spherical cobalt oxyhydroxide.

[0061] 2) Take out the reaction product spherical cobalt oxyhydroxide in 1), repeatedly wash with deionized water and suction filter to preserve the obtained spherical cobalt oxyhydroxide;

[0062] 3) Mix 3 kg of the spherical cobalt oxyhydroxide obtained in 2) with an aqueous solution containing 1 kg of saturated lithium hydroxide and put it into a high-pressure hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction kettle should be heated rapidly to 200°C and Insulated for 1 hour to obtain spherical lithium cobaltate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com