Phosphogypsum ball and preparation method and application thereof

A technology of gypsum balls and phosphogypsum, which is applied in the field of utilization of phosphogypsum, a solid waste of phosphorus chemical industry, can solve the problems of affecting the quality of cement, difficult to popularize and apply, and low strength, and achieve good economic and social benefits, reduce costs, and facilitate transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

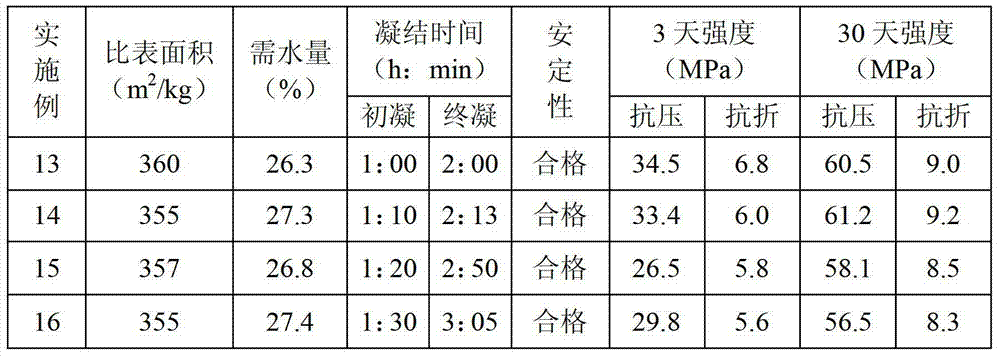

Examples

preparation example Construction

[0021] The present invention also provides a preparation method for the above-mentioned phosphogypsum balls, specifically: mixing various raw materials in any order, then granulating and aging to obtain phosphogypsum balls, and the raw materials are calculated in parts by weight: phosphogypsum spheres 82-95 parts, 3-10 parts of alkaline additives, 2-8 parts of gelling agent; wherein, the phosphorus-containing gypsum is a mixture of dihydrate gypsum and hemihydrate gypsum, and the weight ratio of dihydrate gypsum and hemihydrate gypsum is: 85-95: 5-15.

[0022] Preferably, the preparation method of the above-mentioned phosphogypsum balls is as follows: the phosphogypsum is firstly mixed with the basic additive, then the gelling agent is added, and then granulated and aged to obtain the phosphogypsum balls.

[0023] Preferably, in the above-mentioned preparation method of phosphogypsum balls, aging is performed for 10-30 days.

[0024] Preferably, the above-mentioned preparatio...

Embodiment 1

[0031] Take 85 parts of dihydrate gypsum, 8 parts of hemihydrate gypsum, 5 parts of lime, and 2 parts of bentonite. After the ingredients are mixed and stirred thoroughly, they are sent to a disc granulator. The disc speed is 13 rpm and the motor power is 11kw. Form into balls under certain conditions, store and age naturally for 15 days, and finally obtain modified phosphogypsum balls. The moisture content of the obtained phosphogypsum balls is 8wt%, and the soluble P 2 o 5 Content 0.05wt%, pH value 8.0, SO 3 : 41.55%, particle strength 52N, particle size 10mm.

Embodiment 2

[0033] Take 86 parts of dihydrate gypsum, 8 parts of hemihydrate gypsum, 3 parts of lime, and 3 parts of bentonite. After the ingredients are fully mixed and stirred, they are sent to a disc granulator. The disc speed is 13 rpm and the motor power is 12kw. Form into balls under certain conditions, store and age naturally for 17 days, and finally obtain modified phosphogypsum balls. The obtained phosphogypsum balls had a moisture content of 7.8wt%, soluble P 2 o 5 Content 0.04wt%, pH value 8.2, SO 3 : 42.15%, particle strength 53N, particle size 12mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com