High-crack-resistance low-shrinkage high-ductility mortar and preparation method thereof

A low shrinkage, high ductility technology, applied in the field of high crack resistance, low shrinkage and high ductility mortar, can solve the problems of ECC selection and performance defects, high cost performance, etc., to achieve the effect of being conducive to dispersion, improving cost performance and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

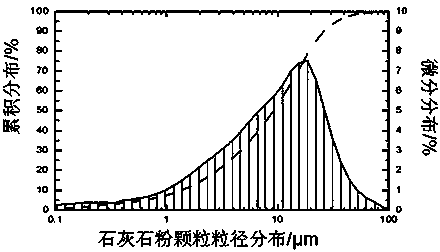

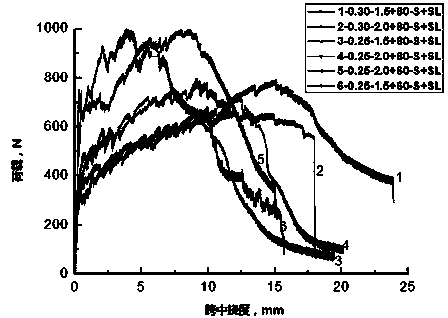

[0036] 1. Mixing ratio:

[0037] See Table 2 for specific ratios.

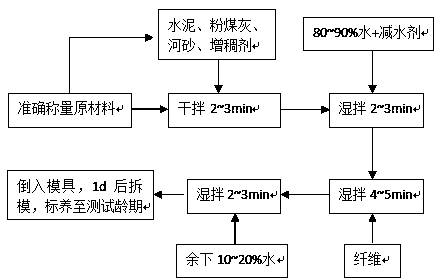

[0038] 2. Preparation method:

[0039] 1) Pour the accurately weighed cement, fly ash, fine aggregate, limestone powder, and thickener into the mixer, and dry mix for 2 minutes until evenly mixed;

[0040] 2) Add 80% of the water dissolved in the water reducing agent into the dry powder, and wet mix for 2 minutes until a slurry with suitable fluidity and cohesion is formed;

[0041] 3) Add artificially pre-dispersed polyvinyl alcohol fibers into the slurry, and wet mix for 4 minutes until the fibers are evenly dispersed in the slurry;

[0042] 4) Add the remaining 20% water into the slurry, and mix for another 2 minutes. After the end, turn off the power of the mixer, and pour the evenly mixed slurry into the mold.

[0043] 3. Maintenance system:

[0044] After 1 day of mold curing under natural conditions, demould, put the specimen into a standard curing room (temperature 20±2°C, relative humidity ≥90%)...

Embodiment 2

[0050] 1. Mixing ratio:

[0051] See Table 2 for specific ratios.

[0052] 2. Preparation method:

[0053] 1) Pour the accurately weighed cement, fly ash, fine aggregate, limestone powder, and thickener into the mixer, and dry mix for 3 minutes until the mixture is uniform;

[0054] 2) Add 90% of the water dissolved in the water reducing agent into the dry powder, and wet mix for 3 minutes until a slurry with suitable fluidity and cohesiveness is formed;

[0055] 3) Add the artificially predispersed polyvinyl alcohol fibers into the slurry, and wet mix for 5 minutes until the fibers are evenly dispersed in the slurry;

[0056] 4) Add the remaining 10% water into the slurry, and mix for another 3 minutes. After the end, turn off the power of the mixer, and pour the evenly mixed slurry into the mold.

[0057] 3. Maintenance system:

[0058] After 1 day of mold curing under natural conditions, demould, put the specimen into a standard curing room (temperature 20±2°C, relative...

Embodiment 3

[0064] 1. Mixing ratio:

[0065] See Table 2 for specific ratios.

[0066] 2. Preparation method:

[0067] 1) Pour the accurately weighed cement, fly ash, fine aggregate, limestone powder, and thickener into the mixer, and dry mix for 2.5 minutes until evenly mixed;

[0068] 2) Add 85% of the water dissolved in the water reducing agent to the dry powder, and mix it wet for 2.5 minutes until a slurry with suitable fluidity and cohesiveness is formed;

[0069] 3) Add the artificially pre-dispersed polyvinyl alcohol fibers into the slurry, and wet mix for 4.5 minutes until the fibers are evenly dispersed in the slurry;

[0070] 4) Add the remaining 15% water into the slurry, and mix for another 2.5 minutes. After the end, turn off the power of the mixer, and pour the evenly mixed slurry into the mold.

[0071] 3. Maintenance system:

[0072] After 1 day of mold curing under natural conditions, demould, put the specimen into a standard curing room (temperature 20±2°C, relative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Four point bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com