Semicrystalline polyester resin for TGIC-cured high-leveling powdery paint and synthetic method thereof

A technology of powder coatings and polyester resins, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as high glass transition temperature and low melt viscosity, and achieve low melt viscosity, high melting point, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment F

[0032] Example F: In a 10-liter reactor, add 1,6-hexanediol in the ratio listed in Table 1, heat up to the material melts; then add terephthalic acid and butyl tin oxide in sequence, and continue to heat up with nitrogen gas Reaction, esterification water starts to be generated and distilled at around 180°C, and then gradually rises to 250°C, and reacts for a total of 8-13 hours from the completion of feeding until 95% of the esterification water is discharged, and the acid value reaches 10-20mgKOH / g After vacuuming for 1~2h, the acid value after vacuuming is 5~8 mgKOH / g, then add acidolysis agent, react for 3~5h, the acid value reaches 38~45mgKOH / g, vacuumize for about 1~4h, and the acid value reaches 30-36mgKOH / g, after cooling down to 200°C, the sample polyester resin can be obtained by discharging.

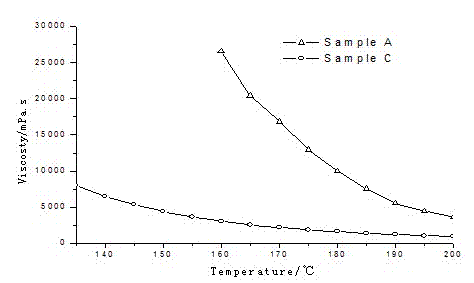

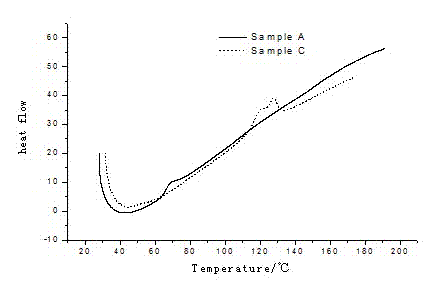

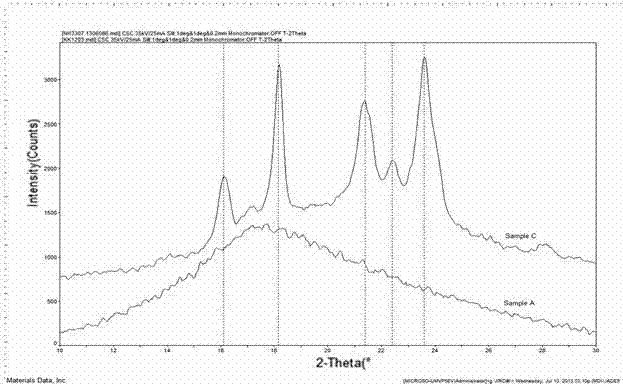

[0033]Acid value: 30~36mgKOH / g; melting point: 100~130°C (DSC); 200°C melt viscosity (ICI cone and plate viscometer): 400~3000mPa·s; crystallinity: 0~60% (XRD).

Embodiment G

[0034] Example G: For Example G, its synthesis process is as follows: In a 10-liter reactor, add 1,6-hexanediol in the proportion listed in Table 1, heat up to the melting of the material; then add terephthalic acid, For butyl tin oxide, nitrogen gas continues to heat up the reaction, esterification water begins to form and distill out around 180°C, and then gradually heats up to 250°C, when the internal temperature of the reactor reaches 250°C, add a proportion of trimethylolpropane and keep it warm Reaction, react for 8-13 hours in total from the start of feeding, until 95% of the esterified water is discharged, the acid value reaches 10-20mgKOH / g, then add acidolysis agent, react for 3-5h, the acid value reaches 38-45mgKOH / g , vacuum polycondensation for about 1-4 hours, the acid value reaches 30-36 mgKOH / g, then cool down to 200 ° C, and then the sample polyester resin can be obtained by discharging.

[0035] Acid value: 30~36mgKOH / g; melting point: 100~130°C (DSC); 200°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com