Polymer by grafting cyclodextrins onto polylysine and preparation method of polymer

A technology of polylysine and succinyl polylysine, which is applied in the field of preparation of pharmaceutical supramolecular carriers, can solve problems such as the difficulty of making medicines alone, and achieve the effects of simple operation, mild reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

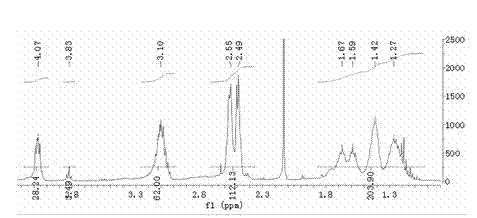

[0041] Embodiment 1: the preparation of N-succinyl polylysine

[0042] Add 5g (1.25mmol) ε-polylysine to 100mL dimethyl sulfoxide and stir evenly at room temperature, add 4.5g (45.0mmol) succinic anhydride to the obtained solution, stir evenly and heat to 45°C for reaction 96h, after the reaction was finished and left to cool, the reaction liquid was dropped into 600mL of acetone and stirred at the same time. 87.5%.

Embodiment 2

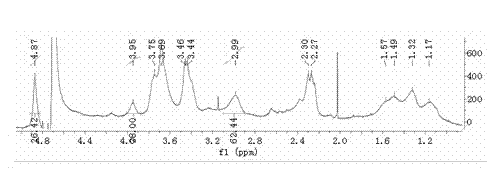

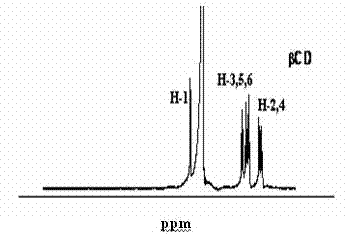

[0043] Example 2: Preparation of mono(6-amino-6-deoxy)-β-cyclodextrin grafted polylysine polymer

[0044] Add 0.5g (0.0735mmol) N-succinyl polylysine to 100ml of solvent water, add EDCI 0.423g (2.207mmol), NHS 0.068g (0.591mmol), and stir at 4°C for 1.0h; Add 2.503 g (2.207 mmol) of mono(6-amino-6-deoxy)-β-cyclodextrin to the obtained solution, stir at 40°C for 60 hours, filter to remove insoluble matter, and place the reaction solution in a dialysis bag with a molecular weight of 10,000 After 96 hours of dialysis, the solvent in the reaction solution was evaporated to dryness after dialysis to obtain mono(6-amino-6-deoxy)-β-cyclodextrin grafted polylysine polymer with a yield of 75.8% and a grafting rate of 32.1%. .

Embodiment 3

[0045] Example 3: Preparation of mono(6-triethylenetetraamine-6-deoxy)-γ-cyclodextrin grafted polylysine polymer

[0046] Add 0.5g (0.0735mmol) N-succinyl polylysine to 100ml solvent N,N-dimethylformamide (DMF), add DCC 0.52g (2.573mmol), HOBT 0.2779g (2.058mmol) , stirred at 0°C for 0.5h, added mono(6-triethylenetetramine-6-deoxy)-γ-cyclodextrin 2.932g (2.058mmol) to the obtained solution, stirred at 20°C for 108h, filtered Remove the insoluble matter; drop the reaction solution into 150ml of acetone to precipitate, filter with suction to obtain the precipitate, then dissolve it in 16ml of water, and finally dialyze it with a dialysis bag with a molecular cut-off of 10,000 for 96 hours, evaporate to dryness and concentrate to obtain the product, with a yield of 70.8% , The grafting rate is 35.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com