Thermoplastic polyurethane composite material and preparation method thereof

A technology of thermoplastic polyurethane and composite materials, which is applied in the field of polymer materials, can solve the problems of poor heat resistance and poor mechanical properties, and achieve the effects of good mechanical properties, stable performance, and increased impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

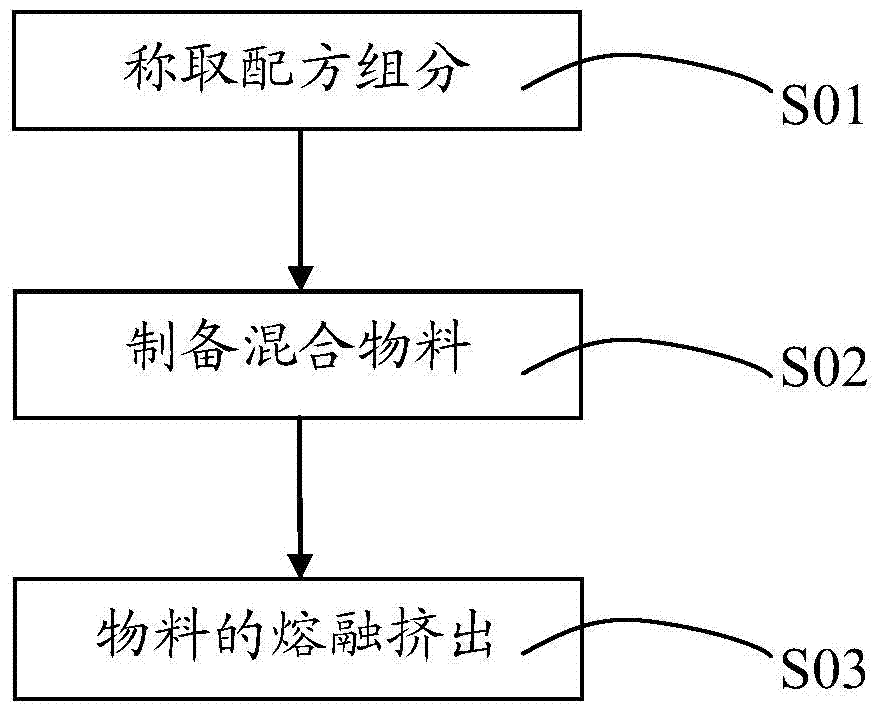

[0027] Correspondingly, an embodiment of the present invention provides a method for preparing a thermoplastic polyurethane composite material, including the following steps, as shown in the attached figure 1 Shown:

[0028] S01. Weighing the formula components: Weighing each component according to the above-mentioned thermoplastic polyurethane composite material formula;

[0029] S02. Prepare a mixed material: perform mixing treatment on the components weighed above except the basalt fiber to obtain a mixed material;

[0030] S03. Melt extrusion of materials: respectively add the mixed material and basalt fiber from different feeding ports, carry out melt extrusion, and granulate.

[0031] Specifically, in the above step S01, the formulation of the thermoplastic polyurethane composite material and the preferred content and type of each component in the formulation are as described above, and will not be repeated here to save space.

[0032]In the above step S02, the time fo...

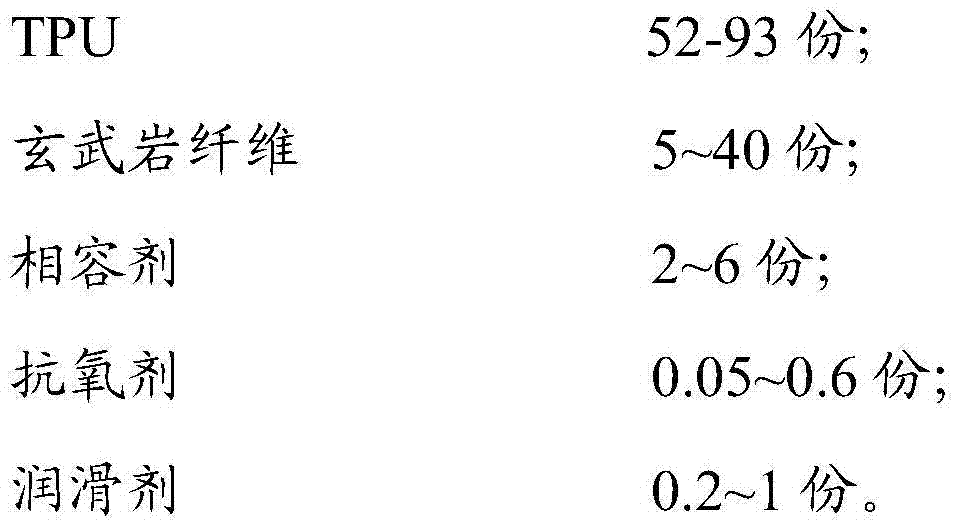

Embodiment 1

[0039] A kind of thermoplastic polyurethane composite material, the formula component that it comprises and the content of corresponding component are shown in embodiment 1 in the following table 1. Among them, the TPU is TPU1195, the compatibilizer is SMA, the antioxidant is Cyanox1790, and the lubricant is polysiloxane.

[0040] Preparation method of thermoplastic polyurethane composite material:

[0041] (1) Weigh each component according to the formula of Example 1 in Table 1;

[0042] (2) Referring to the step (2) of Example 1, the above-mentioned weighed components except the basalt fiber were placed in a medium-speed mixer and mixed for 15 minutes to obtain a mixed material;

[0043] (3) Referring to step (3) of Example 1; 5 parts of basalt fibers were added by side feeding, melted and blended, extruded and granulated to form a composite material. The temperature of each section is: 180°C in the first zone, 190°C in the second zone, 200°C in the third zone, 200°C in t...

Embodiment 2

[0045] A kind of thermoplastic polyurethane composite material, the formula component that it comprises and the content of corresponding component are shown in embodiment 1 in the following table 1. Wherein, the TPU is TPU1195, the compatibilizer is SMA, the antioxidant is Irganox1076 and Irganox168 with a weight ratio of 1:1, and the lubricant is polysiloxane and pentaerythritol stearate with a weight ratio of 1:1.

[0046] Preparation method of thermoplastic polyurethane composite material:

[0047] (1) Weigh each component according to the formula of Example 1 in Table 1;

[0048] (2) Referring to the step (2) of Example 1, the above-mentioned weighed components except the basalt fiber were placed in a medium-speed mixer and mixed for 15 minutes to obtain a mixed material;

[0049] (3) Refer to step (3) of Example 1; add 10 parts of basalt fiber by side feeding, melt blend, extrude and granulate to form a composite material. The temperature of each section is: 180°C in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com