LNG gasification system based on double-heat-source heat pump

A gasification system and dual heat source technology, applied in heat pumps, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as limitations, utilization of LNG cold energy, high heating costs, etc., and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

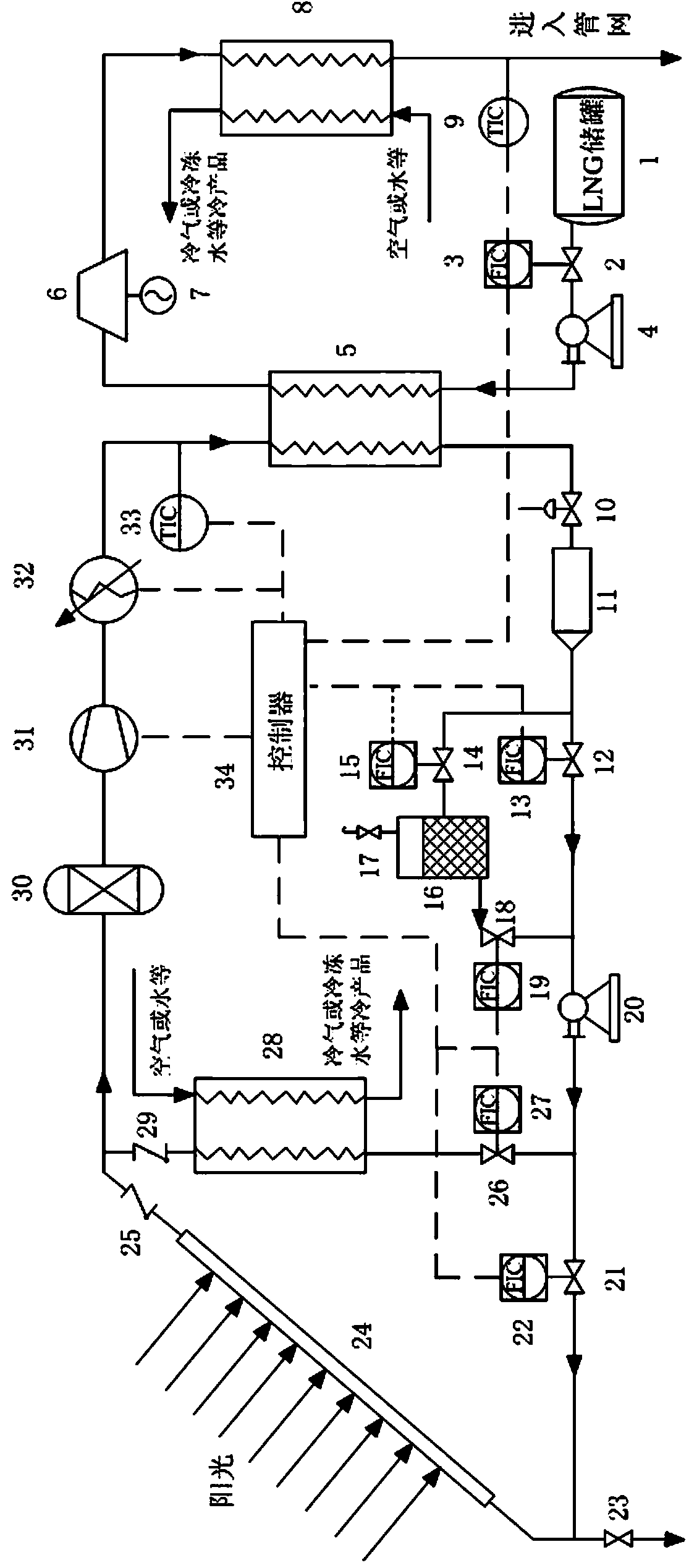

[0031] Such as figure 1 As shown, the LNG gasification system based on the dual heat source heat pump provided by the present invention comprises:

[0032] The LNG gasification heating and expansion main circuit is composed of LNG storage tank 1, electric flow regulating valve 2, LNG booster pump 4, condenser 5, expansion turbine 6 and heat exchanger (8). The main circuit is connected with the natural gas pipe network or user connections;

[0033] An expansion generating unit composed of an expansion turbine 6 and a generator 7;

[0034] Condenser 5, filter 11, cold storage tank 16, working fluid circulation pump 20, first evaporator 24, second evaporator 28 are used to store part of the refrigerant inside the system to prevent liquid shock and Gas-liquid separator 30 for diluting compressor oil due to excessive refrigerant, inverter compressor 31, backup heater 32, electronic expansion valve 10, electric flow control valves 12, 14, 18, 21, 26, breather valve 17, industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com