Large supercritical circulating fluidized bed boiler with low primary wind power consumption

A circulating fluidized bed and supercritical technology, which is applied to fluidized bed combustion equipment, combustion type, and fuel burning in a molten state, etc., can solve the problem of high primary air power consumption, high primary air power consumption, and large energy loss. and other problems, to achieve the effect of simplifying the structure, reducing heat consumption and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

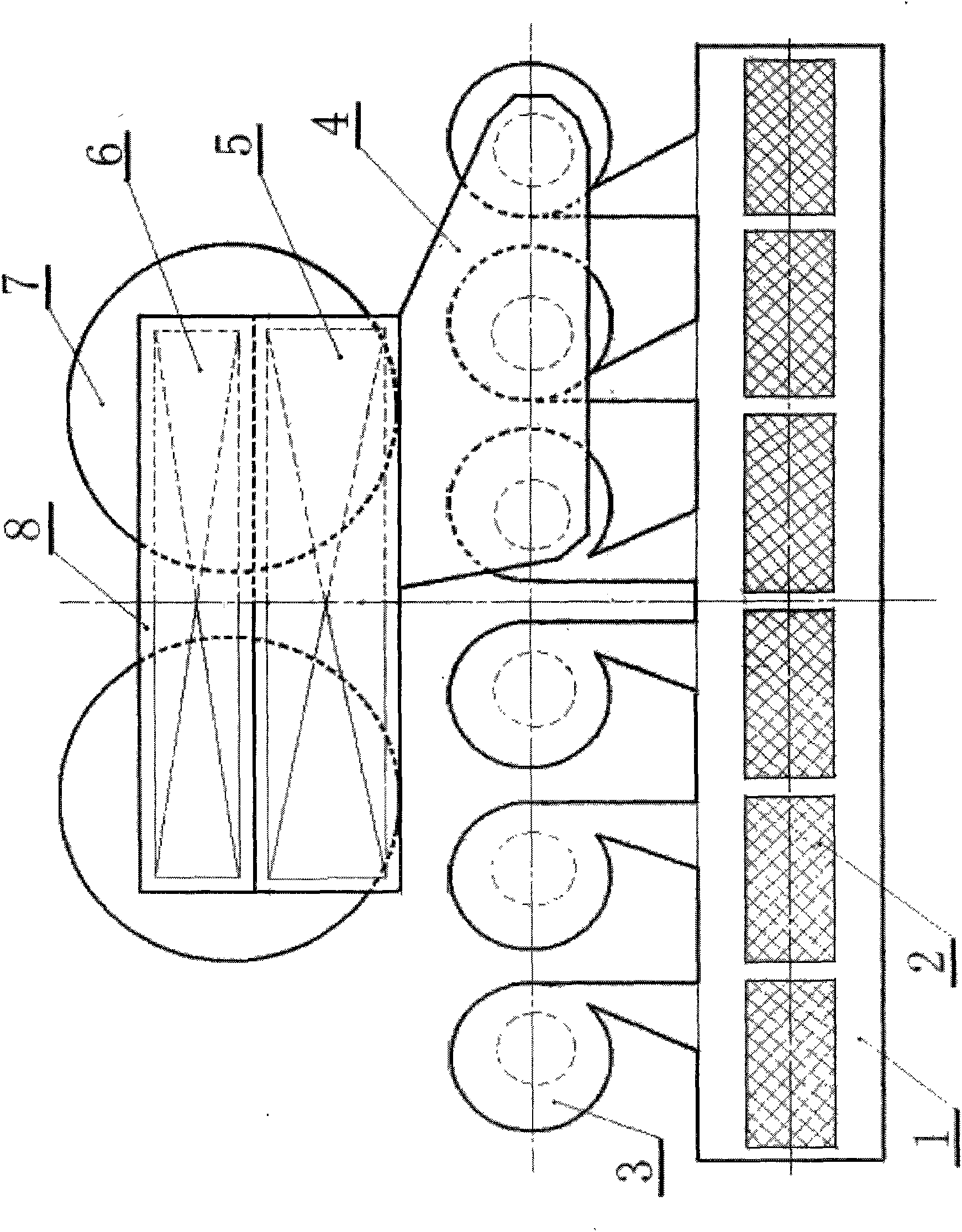

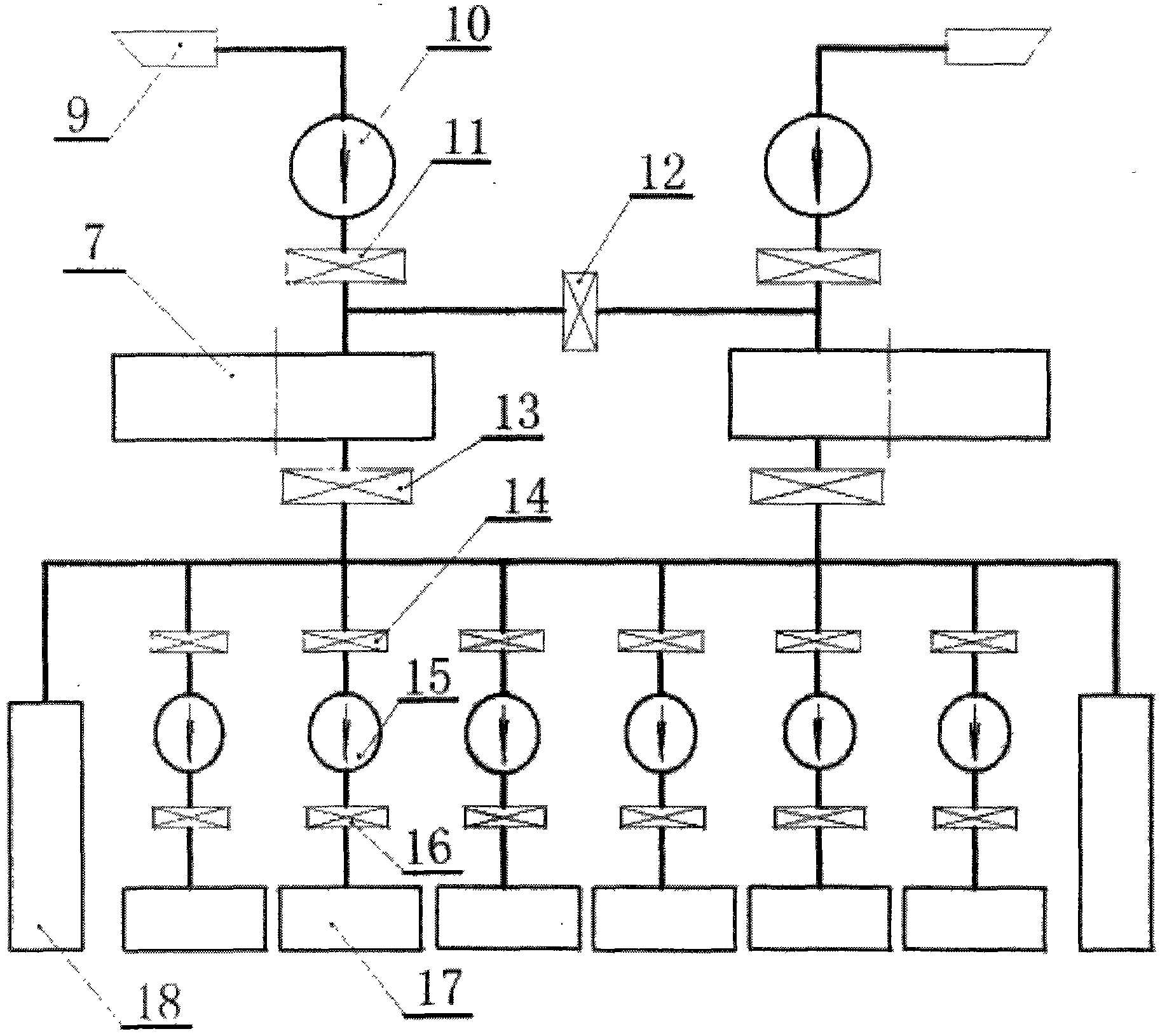

[0041] Combine now figure 1 Taking a 1000MW level supercritical circulating fluidized bed boiler with primary steam temperature / reheat steam temperature design value of 605°C / 613°C as an example to illustrate the optimal way to realize the invention.

[0042] The large-scale low primary air power consumption supercritical circulating fluidized bed boiler of the present invention includes a large width-to-depth ratio furnace composed of membrane water-cooled walls, 6 air distribution plates arranged in a line, 6 primary air bellows, and 6 speed regulators Hot primary fan, 6 cyclone separators, 6 speed-regulating fluidized fans, 6 weighing coal feeders, horizontal connecting flue, tail flue, high-temperature superheater arranged inside the front wall of the furnace, arranged in the furnace High-temperature reheater inside the front wall, low-temperature reheater arranged in the tail front flue, low-temperature superheater arranged in the tail rear flue, economizer arranged in th...

Embodiment 2

[0051] Taking a 600MW level supercritical circulating fluidized bed boiler with primary steam temperature / reheat steam temperature design value of 605°C / 613°C and burning lignite as an example to illustrate the optimization of the invention Way.

[0052] The large-scale low primary air power consumption supercritical circulating fluidized bed boiler of the present invention includes a large width-to-depth ratio furnace composed of membrane water-cooled walls, 4 air distribution plates arranged in a line, 4 primary air bellows, and 4 speed regulators Hot primary fan, 4 cyclone separators, 4 speed-regulating fluidized fans, 4 weighing coal feeders, horizontal connecting flue, tail flue, high-temperature superheater arranged inside the front wall of the furnace, arranged in the furnace High-temperature reheater inside the front wall, low-temperature reheater arranged in the tail front flue, low-temperature superheater arranged in the tail rear flue, economizer arranged in the tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com