Preparation method and application of supercapacitor based on ultrathin two-dimensional nickel hydroxide nano material

A technology of supercapacitor and nickel hydroxide, which is used in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of low specific capacity and short cycle life of supercapacitors, achieve good application prospects, improve cycle life, and improve specific capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Using ultra-thin two-dimensional nickel hydroxide nanomaterials as the active material, acetylene black as the conductive agent, and polytetrafluoroethylene as the binder, the mass ratio of the active material, conductive agent and binder is 80:10: Disperse in absolute ethanol at a ratio of 10, mix evenly with ultrasonic treatment for 30 minutes, and then coat it on the battery-grade nickel foam current collector, dry it in vacuum at 80°C for 10 hours, and press it under a pressure of 10MPa for 30 seconds. into a supercapacitor test electrode.

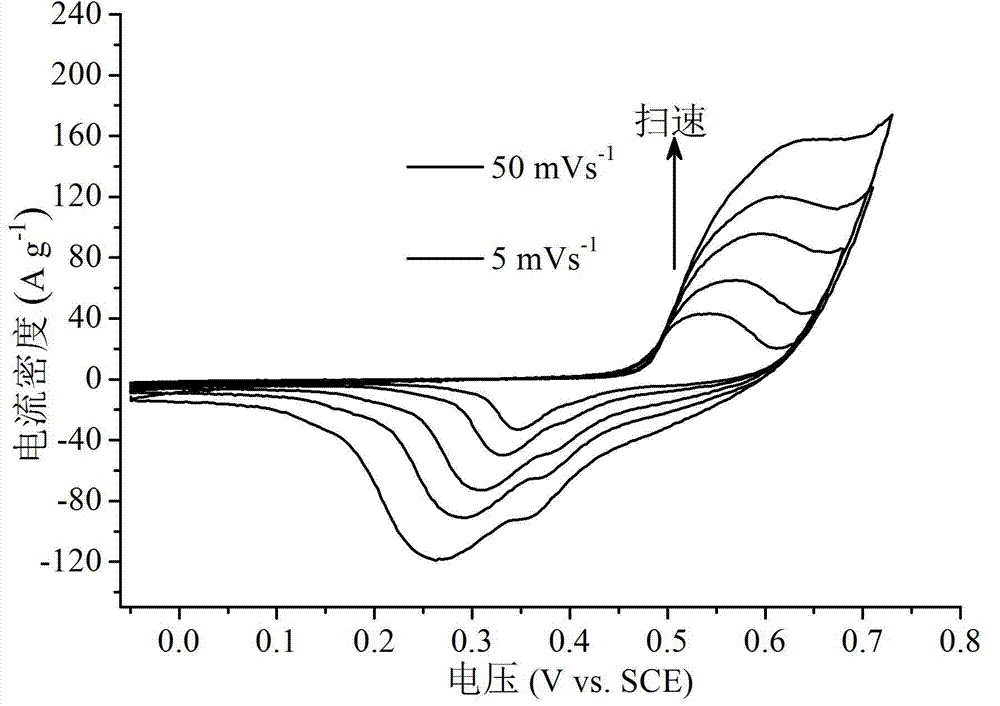

[0028] (2) Soak the supercapacitor test electrode prepared in step 1 in 6 M potassium hydroxide electrolyte for more than 10 hours for activation treatment, use a large-area platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode, 6 The potassium hydroxide solution of M was used as the electrolyte to assemble a simulated supercapacitor for electrochemical performance testing. Cy...

Embodiment 2

[0032] (1) Using ultra-thin two-dimensional nickel hydroxide nanomaterials as the active material, acetylene black as the conductive agent, and polytetrafluoroethylene as the binder, the mass ratio of the active material, conductive agent and binder is 75:15: Disperse in absolute ethanol at a ratio of 10, mix evenly with ultrasonic treatment for 30 minutes, and then coat it on the battery-grade nickel foam current collector, dry it in vacuum at 80°C for 10 hours, and press it under a pressure of 10MPa for 30 seconds. into a supercapacitor test electrode.

[0033] (2) Soak the supercapacitor test electrode prepared in step 1 in 6 M potassium hydroxide electrolyte for more than 10 hours for activation treatment, use a large-area platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode, 6 The potassium hydroxide solution of M was used as the electrolyte to assemble a simulated supercapacitor for electrochemical performance testing. Wh...

Embodiment 3

[0037](1) Using ultra-thin two-dimensional nickel hydroxide nanomaterials as the active material, acetylene black as the conductive agent, and polyvinylidene fluoride as the binder, the mass ratio of the active material, conductive agent and binder is 70:20 Disperse in N-methylpyrrolidone at a ratio of :10, mix evenly with ultrasonic treatment for 30 minutes, then coat it on the battery-grade copper foam current collector, dry it in vacuum at 100°C for 12 hours, and press it under a pressure of 10MPa for 30 seconds Afterwards, a supercapacitor test electrode is made.

[0038] (2) Soak the supercapacitor test electrode prepared in step 1 in 6 M potassium hydroxide electrolyte for more than 10 hours for activation treatment, use a large-area platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode, 6 The potassium hydroxide solution of M was used as the electrolyte to assemble a simulated supercapacitor for electrochemical performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com